SSeeccttiioonn 77

DDIIAAGGNNOOSSTTIICC TTEESSTTSS

Page 60

3. If Step 1 produced spark and Step 2 tested good, set the VOM

to measure DC voltage. Connect one test lead to Wire 15 (J3

Terminal) on ECB. Connect the other test lead to frame

ground. Battery voltage should be measured. Verify that Wire

15 is connected to J3 and that Wire 14 is connected to J2; if

reversed the unit will produce no spark.

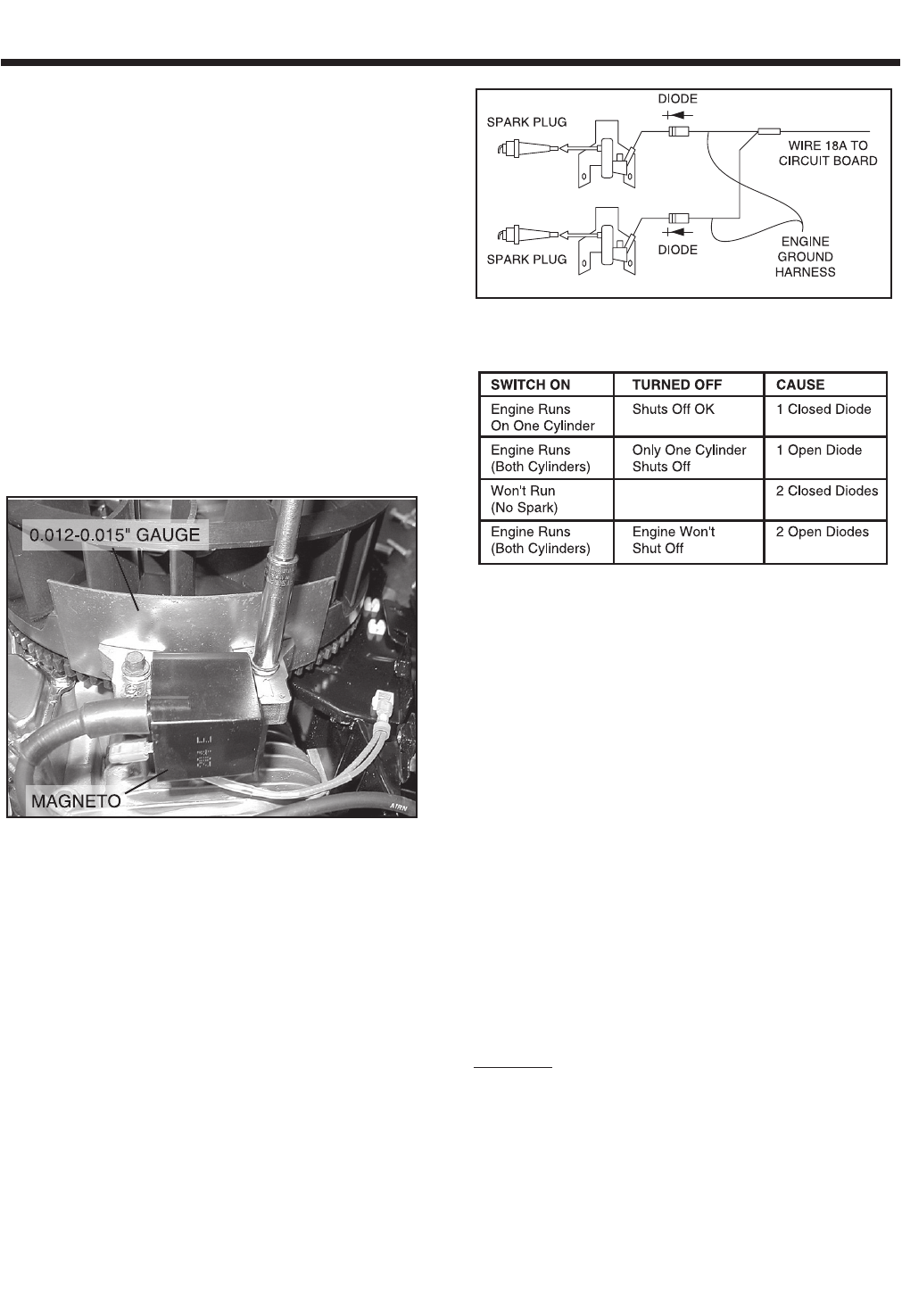

4. Rotate the flywheel until the magnet is under the module

(armature) laminations (see Figure 7-37).

5. Place a 0.012-0.015 inch thickness gauge between the fly-

wheel magnet and the module laminations.

6. Loosen the mounting screws and let the magnet pull the mag-

neto down against the thickness gauge.

7. Tighten both mounting screws.

8. To remove the thickness gauge, rotate the flywheel.

9. Repeat the above procedure for the second magneto.

Figure 7-37. – Setting Ignition Magneto

(Armature) Air Gap

10. Repeat Test 55 and check for spark across the spark tester

gap.

11. If air gap was not out of adjustment, test ground wires.

12. Set the VOM to the diode test position. The meter will display

forward voltage drop across the diode. If the voltage drop is

less than 0.7 volts, the meter will “Beep” once as well as dis-

play the voltage drop. A continuous tone indicates

“

Continuity”

(shorted diode). An incomplete circuit (open diode) will be dis-

played as “OL.”

13. Disconnect the engine ground harness from the ignition mag-

netos and stud connector (see Figure 7-38).

Figure 7-38. – Engine Ground Harness

Figure 7-39. – Diode Failure Diagnosis

14. Connect the positive (+) test lead to Connector ”A” (as shown in

Figure 7-40). Connect the negative (-) test lead to Connector “B.”

a.If meter “Beeps” once and displays voltage

drop, then the diode is good.

b.If the meter makes a continuous tone, the diode

is bad (shorted) and the harness must be

replaced.

c. If the meter displays “OL,” the diode is defective

(open) and the harness must be replaced.

d.Now repeat Steps 14a through 14c with the

negative meter test lead connected to

Connector “C” (Figure

7-40

).

15. If the ground harness tested good, check Wire 18A between

the insulated terminal stud and the J1 Connector for a short to

ground. Set a VOM to measure resistance The ground harness

should still be disconnected from the ignition magnetos.

Connect one meter test lead to Wire 18A which is still removed

from the J1 Connector. Connect the other meter test lead to

frame ground. “Infinity” should be measured.

RESULTS:

1. If “Infinity” was not measured in Step 2b, replace the Engine

Control Board.

Note: If VOM was set to Diode test, a reading of

0.5 volts would be observed when the Start-Stop

Switch is set to STOP. If the VOM was set to resis-

tance, a reading of 0.5 to 1.5M ohms would be