SSeeccttiioonn 77

DDIIAAGGNNOOSSTTIICC TTEESSTTSS

2. If engine cranks in Step 3 when Wire 17 is grounded, but will

not crank when the Switch is set to “START”, replace the Start-

Stop Switch.

3. If the Start-Stop Switch (SW1) failed any part of Steps 5 or 6,

replace the switch.

4. If engine will not crank when Wire 17 is grounded, proceed as

follows:

a.Use a jumper wire to connect the circuit board's

Wire 17 (pin location J1-6) to ground. If engine

does NOT crank, proceed to Test 25.

b.If engine cranks now, but would not crank in

Step 3 of the procedure, check Wire 17 for con-

tinuity between the circuit board and Start-Stop

Switch. If “Continuity” is not measured, repair or

replace Wire 17 between the engine control

board and the Start-Stop Switch.

5. For Problem 9 (Section 6), if switch tests GOOD, go to Test 30.

TEST 25 - CHECK POWER SUPPLY TO WIRE 56

DISCUSSION:

If battery voltage is available to the Engine Controller

board in Test 23, then DC voltage should be delivered

to Wire 56 when the Start-Stop Switch is set to

“START” (Test 24). This test will check to see if the

circuit board is delivering battery voltage to the Wire

56 terminal.

PROCEDURE:

1. Set a VOM to measure DC voltage (12 VDC).

2. Disconnect Wire 56 from its Starter Contactor Relay terminal.

3. Connect the meter positive (+) test lead to Wire 56, just discon-

nected. Connect the other test lead to frame ground. No volt-

age should be indicated.

4. Actuate the Start-Stop Switch to its “START” position. The

meter should indicate battery voltage. If battery voltage is pre-

sent, stop the procedure.

5. Connect the VOM positive (+) test lead to Wire 56 (Pin

Location J1-1) at the Engine Controller Circuit Board. Connect

the other test lead to frame ground.

6. Actuate the Start-Stop Switch to the “START” position. The

meter should indicate battery voltage.

RESULTS:

1. If battery voltage was measured in Step 6, but not in Step 4,

repair or replace Wire 56 between the Engine Controller Circuit

Board and Starter Contactor Relay.

2. If battery voltage was not available in Step 6, replace the

Engine Controller Circuit Board.

3. If battery voltage is available in Step 4 but engine does not

crank, go to Test 26.

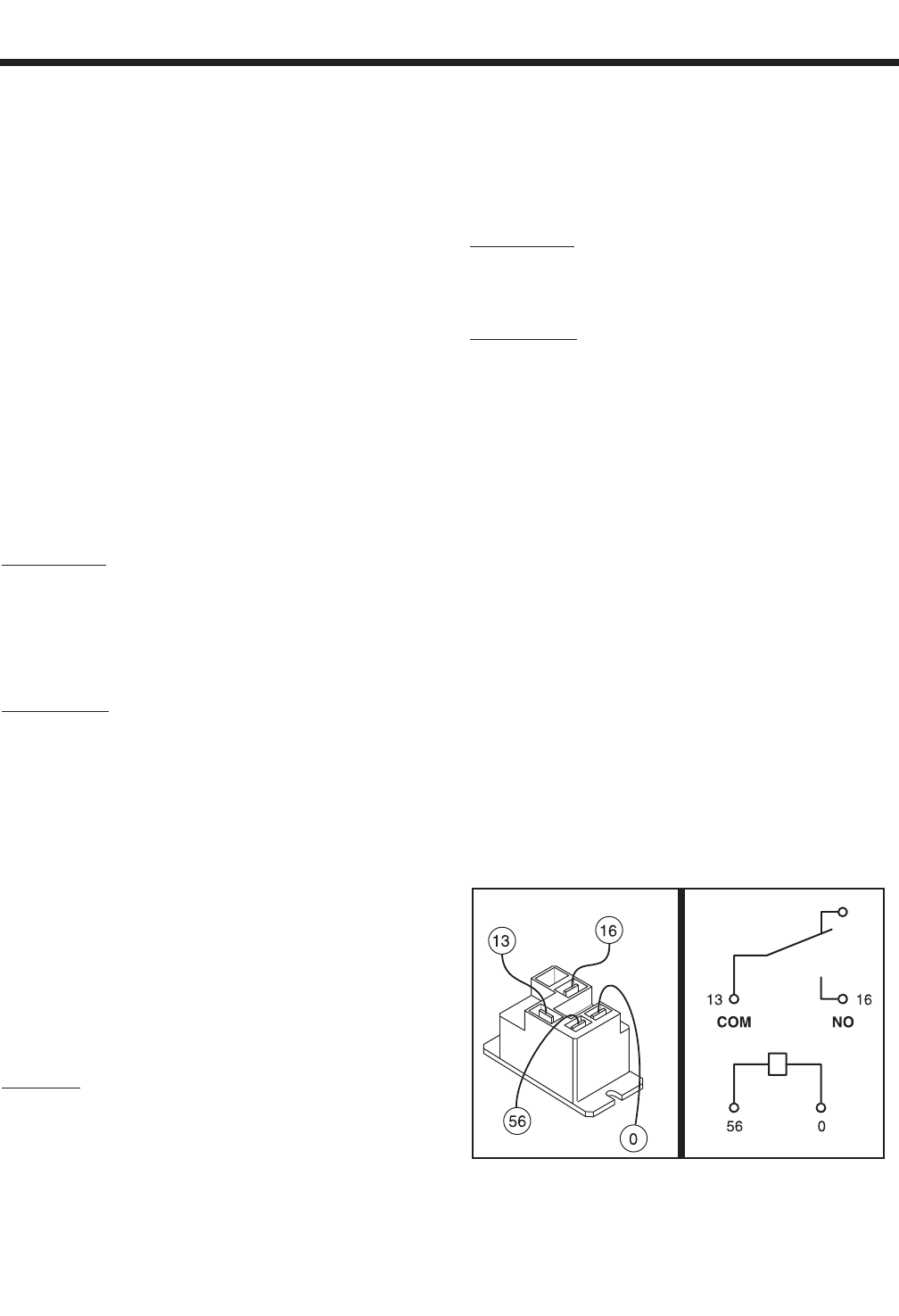

TEST 26- CHECK STARTER CONTACTOR

RELAY

DISCUSSION:

If battery voltage is available to Wire 56 but the

engine won't crank, the possible cause could be a

failed Starter Contactor Relay.

PROCEDURE:

1. Set the VOM to measure resistance (“R x 1” scale). Remove

Wire 0 from the Starter Contactor Relay (SCR). Connect one

meter test lead to Wire 0, and connect the other meter test lead

to frame ground.

“

Continuity” should be measured. Reconnect

Wire 0.

2. Set the VOM to measure resistance (“R x 1” scale). Disconnect

Wire 16 and Wire 13 (Wire 13 is 12VDC isolate from ground)

from the Starter Contactor Relay (SCR). Connect one meter

test lead to an SCR terminal, and connect the other meter test

lead to the remaining SCR terminal. “Infinity” should be mea-

sured. Set the Start-Stop Switch to “START”. The meter should

now read “Continuity”.

Short to Ground:

3. Set the VOM to measure resistance (“R x 1” scale). Disconnect

Wire 56 from the Starter Contactor Relay (SCR). Connect one

meter test lead to the SCR terminal from which Wire 56 was

just removed. Connect the other meter test lead to a clean

frame ground. Starter Contactor Relay coil resistance of 155

ohms should be measured. If

“

Continuity” is measured a short

to ground exists.

Note: Current draw of the Starter Contactor Relay

coil at nominal voltage is approximately 80ma.

Figure 7-19. – Starter Contactor Relay

Page 51