SSeeccttiioonn 77

DDIIAAGGNNOOSSTTIICC TTEESSTTSS

RESULTS:

1.If battery voltage is NOT indicated in Step 1, check

continuity of:

a. Wire 13 between Starter Contactor and

Starter Contactor Relay.

b. Wire 13 between Starter Contactor Relay

and 7.5 Amp Fuse (F1).

c. Wire 15 between the 7.5 Amp fuse (F1) and

the Battery Charge Rectifier.

d. Wire 15 between the Battery Charge

Rectifier and the Engine Controller Board.

Repair, reconnect or Replace bad wiring as necessary.

2. If battery voltage is indicated but engine will not crank, go to

Test 24.

3. If “Continuity” was not measured in Step 3, repair or replace

Wire 0 between the Engine Controller Circuit Board and the

Ground Terminal.

TEST 24 - CHECK START-STOP SWITCH

DISCUSSION:

Engine cranking and startup is initiated when Wire 17

from the Engine Controller board is connected to

frame ground by setting the Start-Stop Switch to

“START”.

Engine shutdown occurs when circuit board Wire 18

is connected to frame ground by the Start-Stop

Switch.

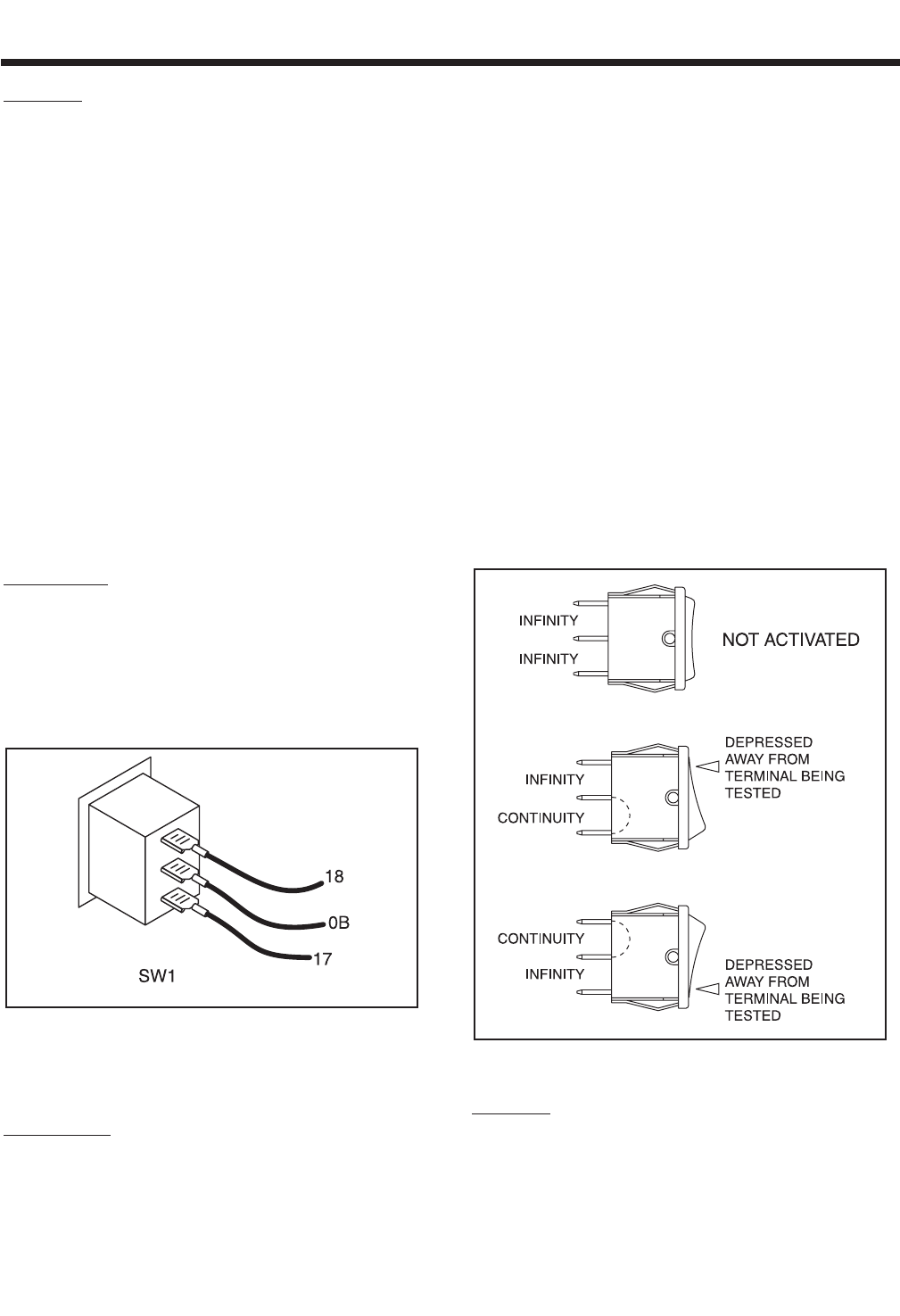

Figure 7-17. – Start-Stop Switch

A defective Start-Stop Switch can result in (a) failure

to crank when the switch is set to “START”, and/or (b)

failure to shut down when the switch is set to “STOP”.

PROCEDURE:

For Problem 6 (Section 6), perform all steps. For

Problem 9, perform Step 1 and Step 5 ONLY.

1. Set a VOM to its “Rx1” scale and zero the meter.

2. Inspect the ground Wire 0B, between the Start-Stop Switch

and the grounding terminal. Connect one meter test lead to

Wire 0B on SW1. Connect the other test lead to a clean frame

ground. “Continuity” should be measured.

3. Disconnect Wire 17 from its Switch terminal and connect it to

frame ground. The engine should crank.

4. Remove the 7.5 amp fuse. Disconnect Wire 18, Wire 0B and

Wire 17 from the Start-Stop Switch (SW1).

5. Connect one test lead to the center terminal of SW1. Connect

the other test lead to an outer terminal of SW1. “Infinity” should

be measured. Remove the test lead from the outer terminal of

SW1 and connect it to the opposite outer terminal. “Infinity”

should be measured.

6. Leave the test lead connected to the center terminal of SW1

from Step 5. Connect the other test lead to an outer terminal.

Depress the switch away from the terminal being tested (see

Figure 7-18). “Continuity” should be measured. Repeat the pro-

cedure with the test lead connected to the other outer terminal.

“Continuity” should be measured.

Figure 7-18. – Test 24, Step 6

RESULTS:

1. If “Continuity” is not measured in Step 2, repair, reconnect or

replace Wire 0B (between Start-Stop Switch and ground termi-

nal) as necessary.

Page 50