SSeeccttiioonn 77

DDIIAAGGNNOOSSTTIICC TTEESSTTSS

Figure 7-24. – Tachometer

TEST BRACKET:

A starter motor test bracket may be made as shown

in Figure 7-25.

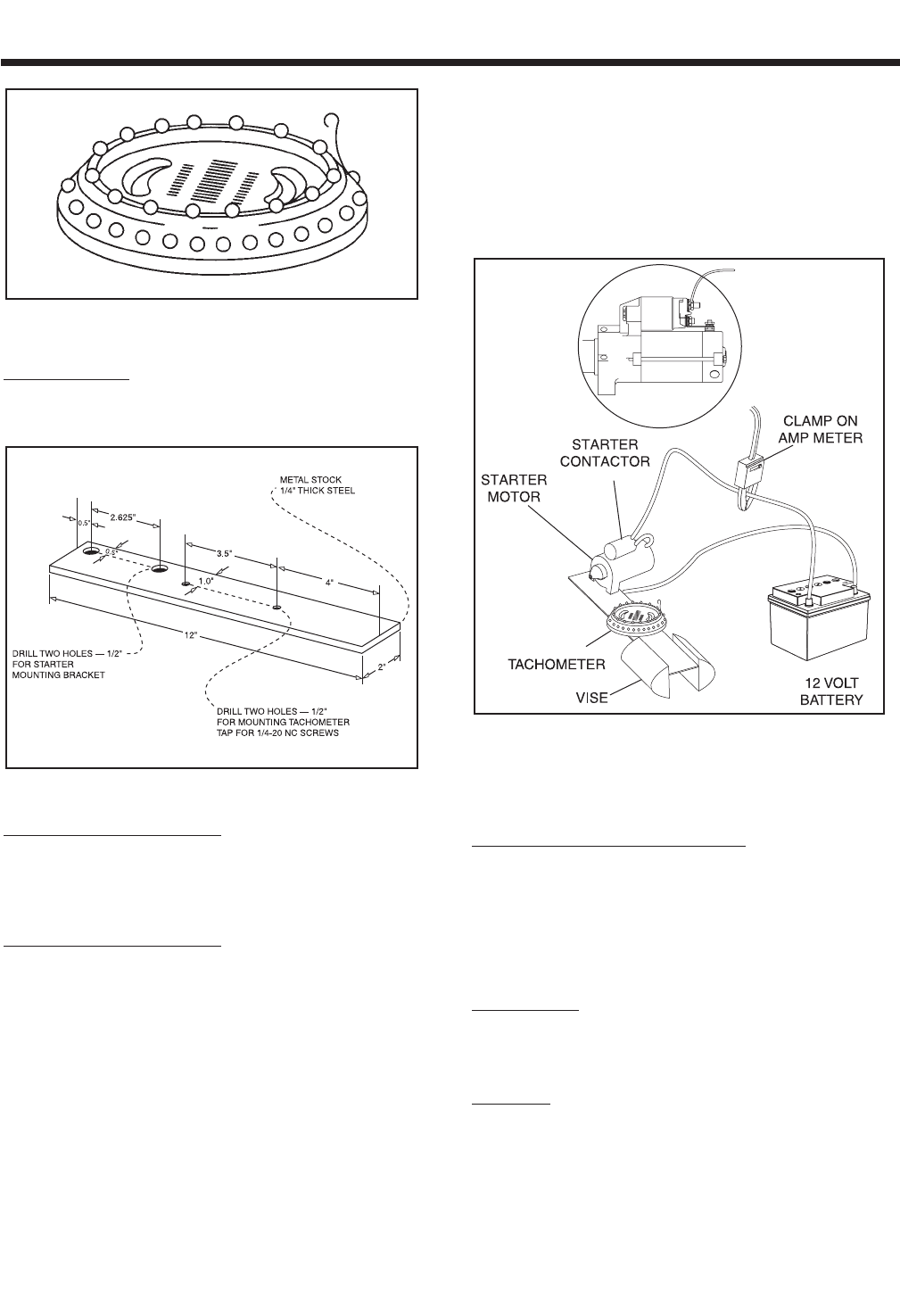

Figure 7-25. – Test Bracket

REMOVE STARTER MOTOR:

It is recommended that the Starter Motor be removed

from the engine when testing Starter Motor perfor-

mance. Assemble starter to test bracket and clamp

test bracket in vise (Figure 7-26).

TESTING STARTER MOTOR:

1. A fully charged 12 volt battery is required.

2. Connect jumper cables and clamp-on ammeter as shown in

Figure 7-26.

3. With the Starter Motor activated (jump the terminal on the

Starter Contactor to battery voltage), note the reading on the

clamp-on ammeter and on the tachometer (rpm).

Note: Take the reading after the ammeter

and tachometer are stabilized, approximately

2-4 seconds.

4. A starter motor in good condition will be within the following

specifications:

MMiinniimmuumm rrppmm 44550000

MMaaxxiimmuumm AAmmppss 5500

Note: Nominal amp draw of starter in generator is

60 amps.

Figure 7-26. – Testing Starter Motor Performance

TEST 28- CHECK FUEL SUPPLY

DISCUSSION (GASOLINE MODELS):

If the engine cranks but won't start, don't overlook the

obvious. The fuel supply may be low. Many RV gen-

erator installations “share” the fuel tank with the vehi-

cle engine. When such is the case, the Installer may

have used a generator fuel pickup tube that is shorter

than the vehicle engine's pickup tube. Thus, the gen-

erator will run out of gas before the vehicle engine.

PROCEDURE:

Check fuel level in the supply tank. Attach a fresh fuel

supply if necessary and restart. Fuel may be stale,

causing a hard start.

RESULTS:

1. If necessary, replenish fuel supply.

2. If fuel is good, go to Test 29 (for Problem 7, Section 6).

Go to Test 32 for Problem 8 (Section 6).

Page 54