SSeeccttiioonn 55

EENNGGIINNEE DDCC CCOONNTTRROOLL SSYYSSTTEEMM

The following chart applies:

CCAABBLLEE LLEENNGGTTHH ((IINN FFEEEETT)) RREECCOOMMMMEENNDDEEDD CCAABBLLEE SSIIZZEE

0-10 No. 2

11-15 No. 0

16-20 No. 000

EFFECTS OF TEMPERATURE:

Battery efficiency is greatly reduced by a decreased

electrolyte temperature. Such low temperatures have

a decided numbing effect on the electrochemical

action. Under high discharge rates (such as crank-

ing), battery voltage will drop to much lower values in

cold temperatures than in warmer temperatures. The

freezing point of battery electrolyte fluid is affected by

the state of charge of the electrolyte as indicated

below:

SSPPEECCIIFFIICC GGRRAAVVIITTYY FFRREEEEZZIINNGG PPOOIINNTT

1.220 -35° F. (-37° C.)

1.200 --20° F. (-29° C.)

1.160 0° F. (-18° C.)

ADDING WATER:

Water is lost from a battery as a result of charging

and discharging and must be replaced. If the water is

not replaced and the plates become exposed, they

may become permanently sulfated. In addition, the

plates cannot take full part in the battery action unless

they are completely immersed in electrolyte. Add only

DISTILLED WATER to the battery. DO NOT USE

TAP WATER.

NOTE: Water cannot be added to some “mainte-

nance-free” batteries.

CHECKING BATTERY STATE OF CHARGE:

Use an automotive type battery hydrometer to test the

battery state of charge. Follow the hydrometer manu-

facturer's instructions carefully. Generally, a battery

may be considered fully charged when the specific

gravity of its electrolyte is 1.260. If the hydrometer

used does not have a “Percentage of Charge” scale,

compare the readings obtained with the following:

SSPPEECCIIFFIICC GGRRAAVVIITTYY PPEERRCCEENNTTAAGGEE OOFF CCHHAARRGGEE

1.260 100%

1.230 75%

1.200 50%

1.170 25%

CHARGING A BATTERY:

Use an automotive type battery charger to recharge a

battery. Battery fluid is an extremely corrosive, sulfu-

ric acid solution that can cause severe burns. For that

reason, the following precautions must be observed:

❏The area in which the battery is being charged must

be well ventilated. When charging a battery, an

explosive gas mixture forms in each cell.

❏Do not smoke or break a live circuit near the top of

the battery. Sparking could cause an explosion.

❏Avoid spillage of battery fluid. If spillage occurs,

flush the affected area with clear water immediately.

❏Wear eye protection when handling a battery.

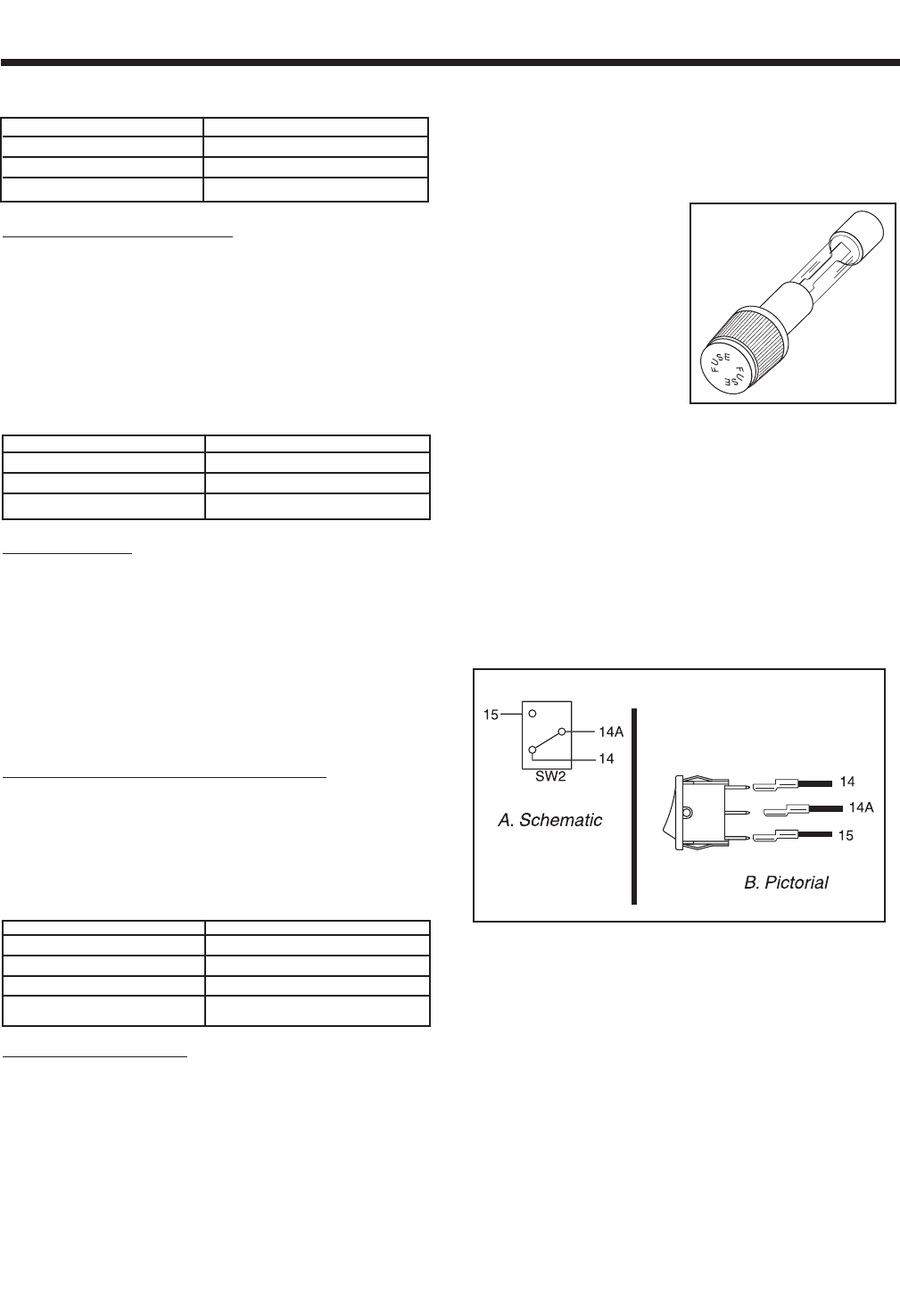

7.5 AMP FUSE

This panel-mounted Fuse

protects the DC control

circuit against overload

and possible damage. If

the Fuse has melted open

due to an overload, nei-

ther the priming function

nor the cranking function

will be available.

FUEL PRIMER SWITCH

Following generator installation and after the unit has

been idle for some time, the fuel supply line may be

empty. This condition will require a long cranking peri-

od before fuel can reach the carburetor. The Fuel

Primer Switch, when actuated to its “PRIME” position

will deliver battery voltage across the closed switch

contacts to the Fuel Pump (FP) to turn the Pump on.

Pump action will then draw fuel from the supply tank

to prime the fuel lines and carburetor.

Figure 5-5. – Primer Switch

START-STOP SWITCH

The Start-Stop Switch allows the operator to control

cranking, startup and shutdown. The following wires

connect to the Start-Stop Switch:

1. Wire No. 17 from the Engine Controller circuit board. This Is

the CRANK and START circuit. When the Switch is set to

'START”, Wire 17 is connected to frame ground via Wire OB.

a. With wire 17 grounded, a Crank Relay on

the circuit board energizes and battery volt-

Page 25

Figure5-4