20 Operation

MAN0943 (07/12/2011)

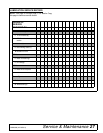

1. Leave standard flails located between the rows.

2. Remove others and install shorter flails to follow

ground contour. Be sure to mount the same size

flails on opposite sides of the tube. Measure the

row spacing and flail position carefully to minimize

ground contact. See page 36 and page 37.

.

Figure 9. Optional Flail Contour

Figure 10. “L” Flails

Figure 11. Cup Flails

Setting Flail Height

1. Be sure wheels are set to follow in the center of

furrow row. Set flails 3 to 6 inches (75 to 150

mm) above the ground. (See Balance Statement,

page 5.)

2. Align the unit with the working area on or between

rows on flat farming.

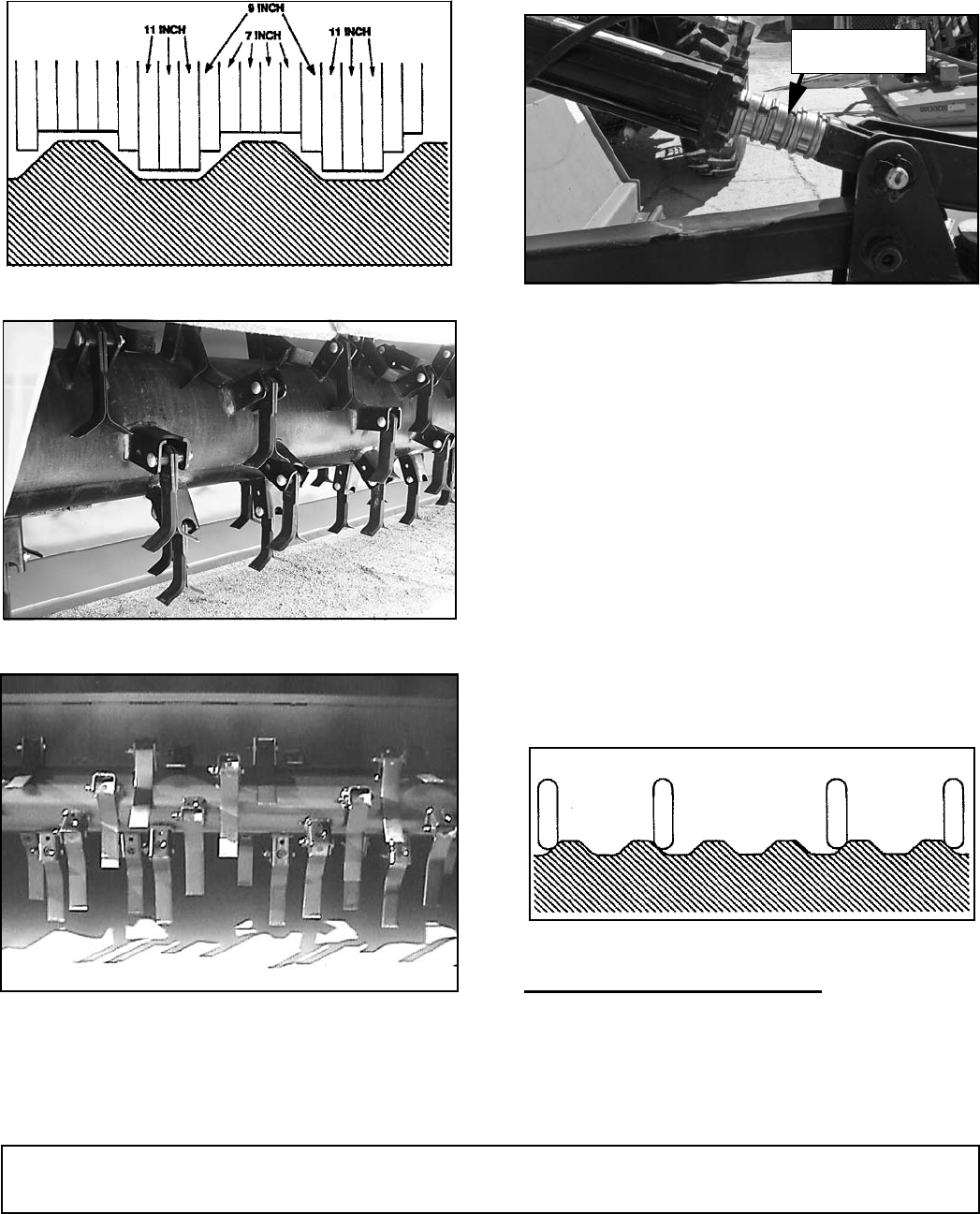

3. Use stroke control spacers on four cylinders to set

cutting height.

Figure 12. Setting Flail Height

Setting Caster Wheels

Normally, wheels are set to track in the row centers,

between the raised seed beds. Tire position will deter-

mine flail height, but depth of furrow is also a factor in

setting flail height. In some conditions the furrow

between the seed beds is deeper on the ends, where

irrigation waters enter the field. As furrows change

depth, flail height will change.

To compensate for the depth change, move the caster

wheels against the side of the outer seed bed (see Fig-

ure 13). The wheels will then tend to climb up the side

of the seed bed and prevent the flails from hitting the

top of the bed.

Set the flail height after the wheels have been moved

against the seed bed.

Figure 13. Wheel Position

STARTING THE SHREDDER

1. Run tractor engine at low idle.

2. Slowly engage PTO control to start the shredder.

3. Slowly bring tractor engine to rated PTO speed.

Never exceed rated speed.

DP13

DP14

Stroke Control

Spacers

DP124