16 Operation

MAN0943 (07/12/2011)

Figure 2. Tractor Front Weight

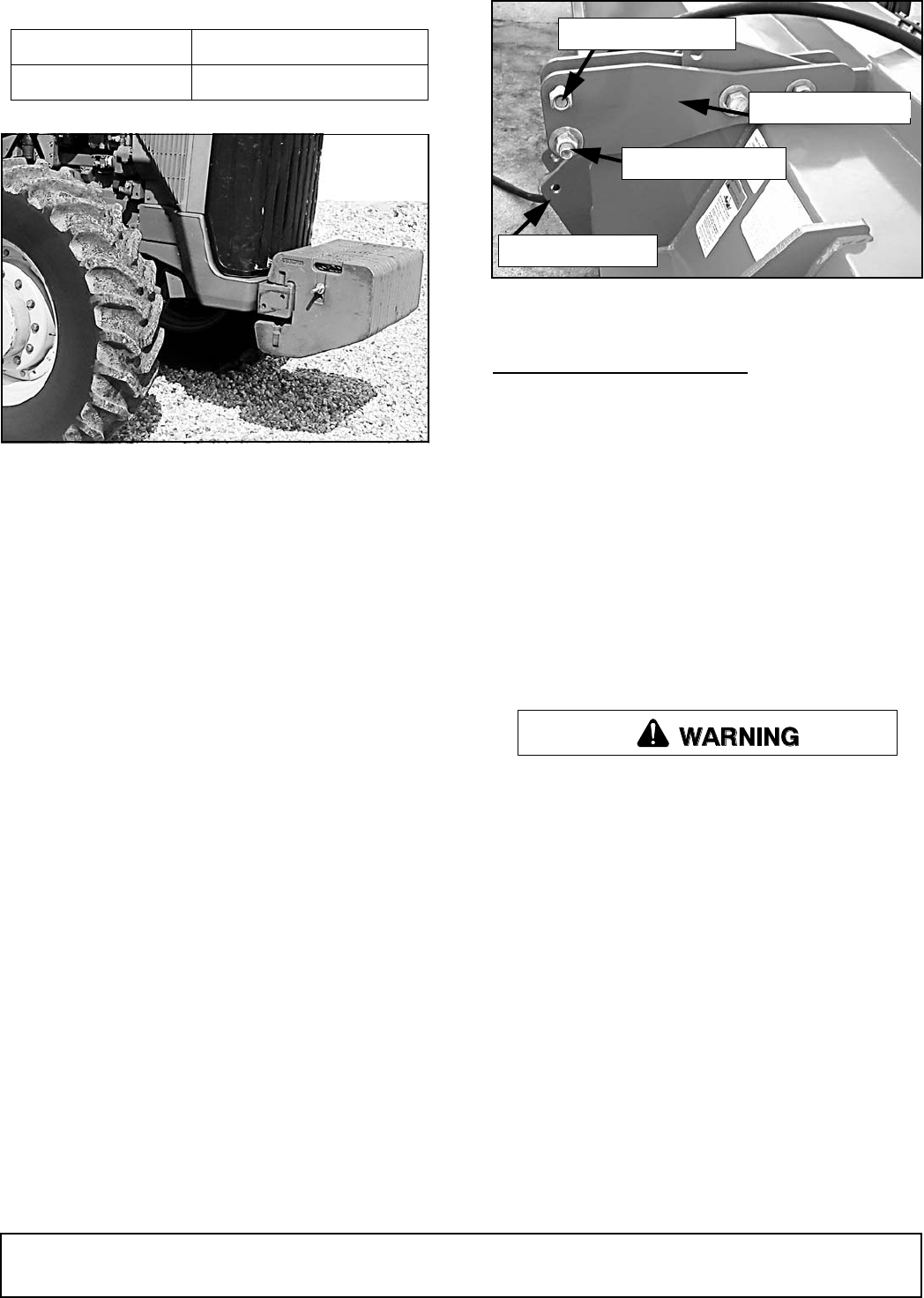

3. 3-Point Hitch

The 3-point hitch models require that the tractor be

equipped with a Category II or Category III 3-point

hitch. If the hitch can be converted from one to the

other, use a Category III to provide a wider stance and

more stability.

Use the upper top link hole for Category III and the

lower hole for Category II as shown in Figure 3.

For easier attachment, use a quick hitch. If not using a

quick hitch, use optional hitch extension.

4. Hydraulic Requirements when Using Center

Cutter Options

The tractor hydraulic system must be capable of 8 gpm

(30 lpm) at 1500 psi (10,335 kPa). The system cannot

exceed 28 gpm or 3000 psi. Either closed-centered or

open-centered systems can be used.

5. Load Sensing Hydraulics (3-Point Models Only)

Many newer tractors are equipped with “load sensing”

hydraulics. The operator is responsible for setting the

tractor hydraulic system to provide “float” on the 3-point

hitch. Refer to the tractor manual for specific instruc-

tions.

The “float” feature will allow the unit to follow the

ground contours during operation. This applies to 3-

point mounted machines only.

NOTICE

■ Do not use PTO shaft adapters. They will

change the drawbar dimension and can cause driv-

eline failures.

Figure 3. 3-Point Hitch Attachment

NOTICE

PTO DRIVELINE LENGTH

■ The unit is equipped with a PTO driveline long

enough to fit any tractor and 3-point linkage sys-

tem.

■ The operator is responsible for measuring the

dimensions of the driveline through its working

range. These dimensions will indicate if the drive-

line requires shorting to operate on the particular

tractor/unit attachment system. The operator must

check dimensions before using the unit for the first

time and each time a different tractor is used with

the unit.

■ Use the following procedure when determining

driveline dimension:

Keep bystanders away from equipment.

1. Clear the area of all bystanders.

2. Attach the 3-point hitch to the unit but not the PTO

driveline.

3. Raise the unit until the tractor PTO and gearbox

shafts are the same height.

4. Measure the dimension between the shaft grooves

on the tractor and implement ends. If this

dimension is less than 34.81 inches, the shaft will

require shortening.

5. Move the unit to its highest and lowest working

position and measure this dimension again. [The

unit’s shaft can telescope (see Figure 5) before it

has been shortened.]

6. If required, shorten the shaft to prevent bottoming

out during use. NOTE: An extra inch of

compression space in the shaft can eliminate

bottoming out during use. Measure to make sure.

Table 1: Tractor Horsepower (6-8) vs. Unit Width

Width Minimum Horsepower

30’ 180

DP10

Top Link Assembly

Upper Top Link Hole

Lower Top Link Pin

Lower 3-Point Pin

DP11