Form 436, Page 8

9. Venting (cont'd)

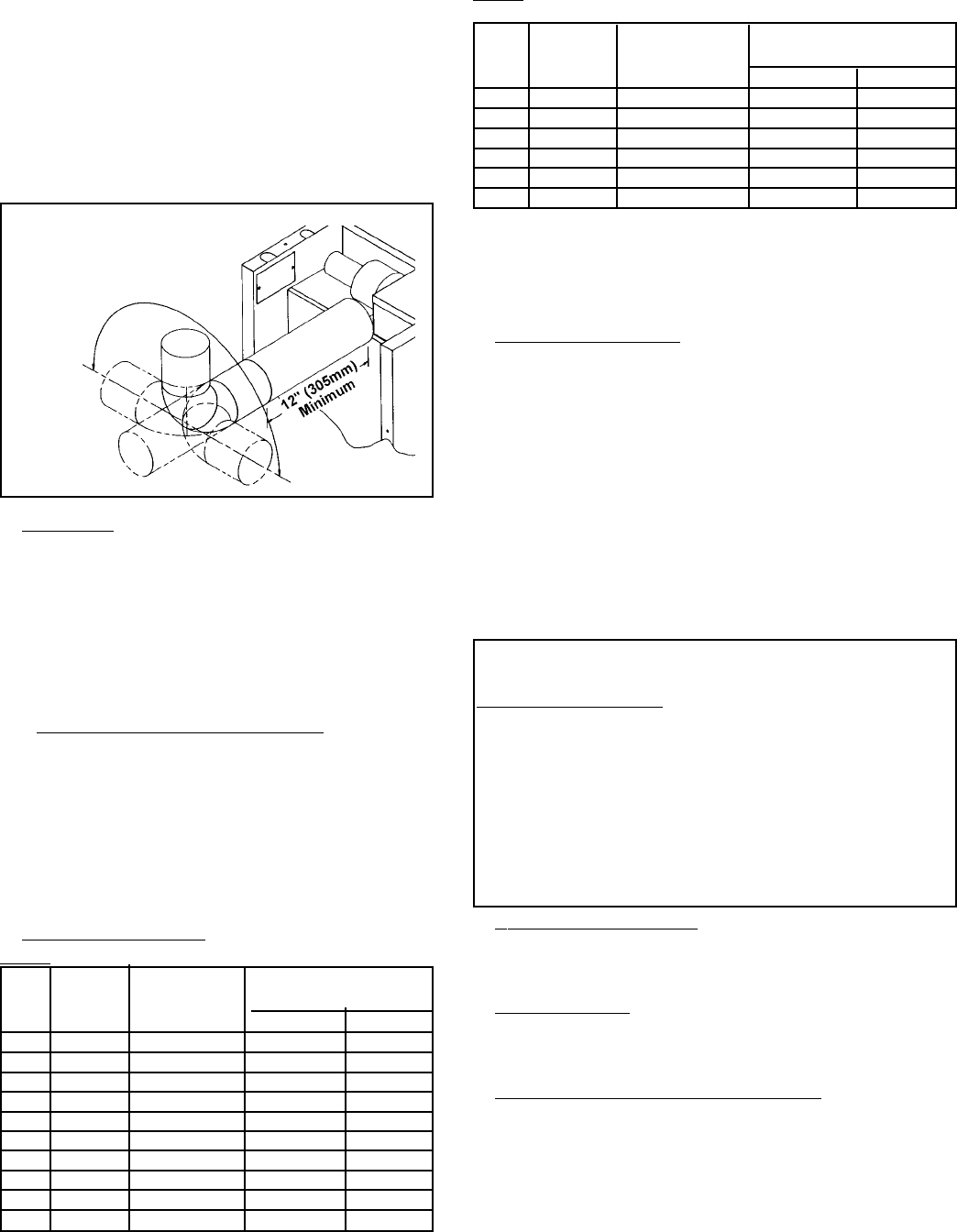

Venter Outlet Attachment Requirements:

• If the pipe used in the vent run is larger than the diameter of the

venter outlet (See Vent Length Table 2), make the transition at

the venter outlet.

• A minimum of 12" of straight pipe is required at the venter

outlet (or transition fitting) before installing an elbow in the

vent system. An elbow should never be attached directly to the

venter. An elbow attached to the straight pipe can be in any

position at or above horizontal. See Figure 5.

2. Vent Pipe

If installed with a horizontal vent run, use either vent pipe approved

for a Category III heater or appropriately sealed 26-gauge galva-

nized steel or equivalent single-wall pipe.

If at least half of the equivalent length of the vent system is verti-

cal, vent pipe approved for a Category I heater may be used. Single-

wall pipe or double-wall (Type B) vent pipe are suitable for use

with a Category I heater.

Use only one of the flue pipe diameters listed in the Vent Length

Tables for the furnace size being installed.

2A. Vent Pipe Diameter Reduction

If at least half of the equivalent length of the vent system is verti-

cal, the vent pipe diameter may be reduced one inch from the stan-

dard diameter listed in Vent Length Table 1. Only single-wall pipe

is suitable for use when reducing the pipe diameter. A taper-type

reducer must be used. The maximum allowable vent length remains

the same. If required, double wall pipe may be used at the terminal

end as shown in Figure 6. (Use the equivalent length for elbows as

shown in Vent Length Table 1 for the standard vent pipe diameter.

All elbows used in the vent system must be considered.)

3. Vent Length Tables

Table 1: Maximum Permissible Vent Lengths

Vent Pipe Maximum Equivalent Straight

Model Diameter Vent Length* Length** - ft (m)

-" (mm) - ft (m) 90

o

Elbows 45

o

Elbows

25 4"(102) 30 ft (9.1 m) 3.5' (1 m) 1.8' (.5 m)

50 4"(102) 40 ft (12.2 m) 5' (1.5 m) 2.5' (.8 m)

75 4"(102) 50 ft (15.2 m) 7' (2.1 m) 3.5' (1.1 m)

100 4"(102) 50 ft (15.2 m) 7' (2.1 m) 3.5' (1.1 m)

125 5"(127) 50 ft (15.2 m) 5' (1.5 m) .5' (.8 m)

165 5"(127) 50 ft (15.2 m) 9' (2.7 m) 4.5' (1.4 m)

200 5"(127) 50 ft (15.2 m) 8' (2.4 m) 4.0' (1.2 m)

250 5"(127) 50 ft (15.2 m) 10' (3.0 m) 5' (1.5 m)

300 6"(152) 50 ft (15.2 m) 11' (3.4 m) 5.5' (1.7 m)

400 6"(152) 50 ft (15.2 m) 15' (4.6 m) 7.5' (2.3 m)

Figure 5 - Alternate Vent

Directions (vent in any

position above horizontal;

minimum of 12" of straight

pipe

required

before

an

elbow)

Table 2: Optional Maximum Permissible Vent Lengths

(Requires an increase in vent pipe diameter.)

Vent Pipe Maximum Equivalent Straight

Model Diameter Vent Length* Length** - ft (m)

- " (mm) - ft (m) 90

o

Elbows 45

o

Elbows

100 5" (127) 60 ft (18.3 m) 8' (2.4 m) 4.0' (1.2 m)

165 6" (152) 60 ft (18.3 m) 10' (3.0 m) 5.0' (1.5 m)

200 6" (152) 60 ft (18.3 m) 12' (3.7 m) 6.0' (1.8 m)

250 6" (152) 70 ft (21.3 m) 8' (2.4 m) 4.0' (1.2 m)

300 7" (178) 70 ft (21.3 m) 13' (4.0) 6.5' (2.0 m)

400 7" (178) 90 ft (27.4 m) 14' (4.3) 7.0' (2.1)

*Note 1: If the system contains all vertical pipe or a combination of horizontal

and vertical vent pipe, the Maximum Permissible Vent Length shown in Tables 1

and 2 may be increased one foot for each foot vertical rise up to a maximum

increase of 10 feet for model sizes 25 thru 100 and up to 20 feet for model sizes

125 thru 400.

**Reduce the maximum vent length by the amount indicated for each elbow.

4. Vent System Joints

Vent system joints depend on the installation and the type of pipe being

used.

• If using single wall, 26-gauge or heavier galvanized pipe, secure slip-

fit connections using sheet metal screws or rivets. Seal pipe joints ei-

ther with tape suitable for 550

o

F (such as Option FA1, P/N 98266) or

high-temperature silicone sealant.

• If using Category III vent pipe, follow pipe manufacturer's instructions

for joining pipe sections. When attaching Category III pipe to the ven-

ter outlet or the vent cap, make secure, sealed joints following a proce-

dure that best suits the style of Category III pipe being used.

• If using double-wall (Type B) vent pipe (allowed only if 1/2 of the

equivalent vent length is vertical), follow pipe manufacturer's instruc-

tions for joining pipe sections. For joining double-wall pipe to the ven-

ter outlet collar, single-wall pipe, and/or the vent cap, follow the in-

structions below.

Instructions for attaching double-wall (Type B) vent pipe to the venter out-

let, a single-wall pipe run, or to the vent cap (use these instructions for ei-

ther full length double-wall or terminal only):

Hardware and Sealant Required: 3/4" long sheetmetal screws; and a tube of RTV

1) Look for the "flow" arrow on the vent pipe; attach according to the arrow.

Slide the pipe so that the venter outlet, the single-wall pipe, or the vent cap is

inside the double-wall pipe.

2) Drill a hole through the pipe into the outlet collar, the single-wall pipe, or the

vent cap. (Hole should be slightly smaller than the sheet metal screw being used.)

Using a 3/4" long sheet metal screw, attach the pipe. Do not overtighten. Repeat,

drilling and inserting two additional screws evenly spaced (120

o

apart) around

the pipe.

3) Use RTV to seal any gaps. If there is an annular opening, run a large bead of

RTV in the opening. The bead of RTV must be large enough to seal the opening,

but it is not necessary to fill the full volume of the annular area.

5. Vent System Support

Support lateral runs every six feet, using a non-combustible material such

as strap steel or chain. Do not rely on the heater for support of either hori-

zontal or vertical vent pipe

6. Condensation

Single wall vent pipe exposed to cold air or run through unheated areas

must be insulated. Where extreme conditions are anticipated, install a means

of condensate disposal.

7. Vent Terminal (Pipe and Vent Cap)

The vent system must be terminated with a suitable vent cap that is the

same size as the vent run.

Heaters installed in Canada must be equipped with the vent cap sup-

plied as optional equipment by the heater manufacturer (Option CC1 or

Option BT2). Heaters installed in the United States must be equipped

with the heater manufacturer's vent cap, a Type L Breidert Air-x-hauster

®

vent cap, or equivalent. Use of a vent cap supplied by the pipe manufac-