Form 436, Page 6

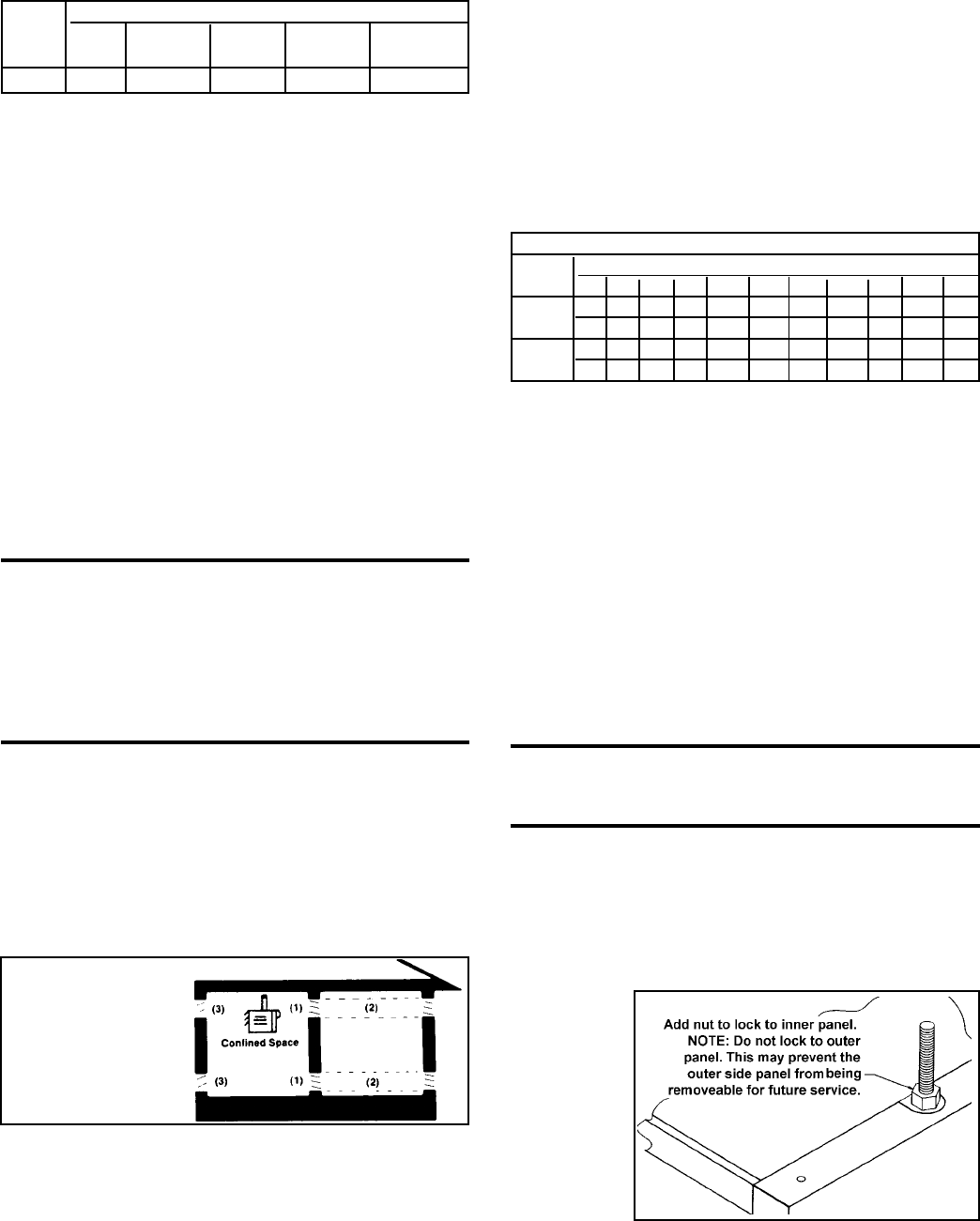

Figure 1 -

Confined Space: A

space whose volume is

less than 50 cubic feet

per 1000 BTUH of the

installed appliance

input rating

Add total BTUH of all appliances in the confined space and divide by

figures below for square inch free area size of each (top and bottom)

opening.

Figure 2 -

Suspension

* When supplied with optional downturn nozzle, bottom clearance is

42"(1067mm). For service purposes, on standard units, bottom clear-

ance exceeding minimum (12" or 305mm) is not required but may

be desirable.

** For servicing purposes only, rear must remain full open.

All fuel-burning equipment must be supplied with the air that enters

into the combustion process and is then vented to the outdoors. Suffi-

cient air must enter the equipment location to replace that exhausted

through the heater vent system. In the past, the infiltration of outside

air assumed in heat loss calculations (one air change per hour) was

assumed to be sufficient. However, current construction methods uti-

lizing more insulation, vapor barriers, tighter fitting and gasketed doors

and windows or weather-stripping, and mechanical exhaust fans may

now require the introduction of outside air through wall openings or

ducts.

The requirements for combustion and ventilation air depend upon

whether the unit is located in a confined or unconfined space. An "un-

confined space" is defined as a space whose volume is not less than 50

cubic feet per 1000 BTUH of the installed appliance. Under all condi-

tions, enough air must be provided to ensure there will not be a nega-

tive pressure condition within the equipment room or space. For spe-

cific requirements for confined space installation, see Paragraph 7.

WARNING: These power-vented unit heaters are

designed to take combustion air from the space

in which the unit is installed and are not designed

for connection to outside combustion air intake

ducts. Connecting outside air ducts voids the

warranty and could cause hazardous operation.

See Hazard Levels, Page 2.

7. Combustion Air Requirements

for a Heater Located in a

Confined Space

Do not install a unit in a confined space without providing wall open-

ings leading to and from the space. Provide openings near the floor

and ceiling for ventilation and air for combustion as shown in Figure

1, depending on the combustion air source as noted in Items 1, 2, and

3 below the illustration.

6. Clearances and Combustion

Air (cont'd)

1. Air from inside the building -- openings 1 square inch free area per

1000 BTUH. Never less than 100 square inches free area for each open-

ing. See (1) in Figure 1.

2. Air from outside through duct -- openings 1 square inch free area

per 2000 BTUH. See (2) in Figure 1.

3. Air direct from outside -- openings 1 square inch free area per 4000

BTUH. See (3) in Figure 1.

NOTE: For further details on supplying combustion air to a confined

space, see the National Fuel Gas Code ANSI Z223.1a (latest edition ).

8. Suspending the Heater

Before suspending the heater, check the supporting structure to be used

to verify that it has sufficient load-carrying capacity to support the weight

of the unit.

Net Weight (lbs and kg)

Model Size

Type 25 50 75 100 125 165 200 250 300 400

Fan lbs 76 83 92 101 132 154 175 209 226 281

kg 34 38 42 46 60 70 79 95 103 127

Blower lbs 97 104 118 130 180 206 240 278 301 395

kg 44 47 54 59 82 93 109 126 137 179

Model Required Clearances (inches and mm)

Size Top Flue Sides Bottom Rear

Collector

25-400 6"(152) 6"(152) 18"(457) 12"(305) * 24" (610)**

NOTE: If the installation includes an optional stepdown transformer

kit (Option CF or CG), the stepdown transformer bracket is part of the

heater suspension and must be installed prior to hanging the heater.

Follow the instructions on the installation sheet included with the op-

tion kit.

A fan-type unit heater is equipped with standard two-point suspen-

sion. A 3/8-16 threaded hanger bracket assembly is located on each

side of the heater. If a fan-type unit has been ordered with optional,

factory-installed, four-point suspension (Option BJ6), it will have two

threaded hanger brackets on each side.

A blower-type heater is equipped with standard four-point suspen-

sion. Two 3/8-16 threaded hanger bracket assemblies are located on

each side of the unit. Each hanger bracket assembly is designed for

threaded rod attachment.

For both "standard" and "optional" suspension point dimensions, see

Dimension Tables in Paragraph 3. (Note: If installing Option CK19

hanger kit, suspension points change; see Figure 4B.)

WARNING: Suspend the heater only from the

threaded hanger brackets. Do not suspend from

the heater side panel.

When the heater is lifted for suspension, the bottom must be protected.

If the wooden crate bottom has been removed, the bottom of the heater

will have to be supported with plywood or other appropriately placed

material. If the bottom is not supported, the bottom access panel could

be damaged. Also, when lifting a blower unit, support the blower and

motor to prevent the unit from tipping.

All blower models have legs that support the blower assembly during

shipping. After

the unit is sus-

pended, these

legs should be

removed.

Be sure that the

threaded hanger

rods are locked

to the heater as

shown in Figure

2.