Form 436, Page 12

TYPICAL WIRING DIAGRAMS -- Pages 12 - 15

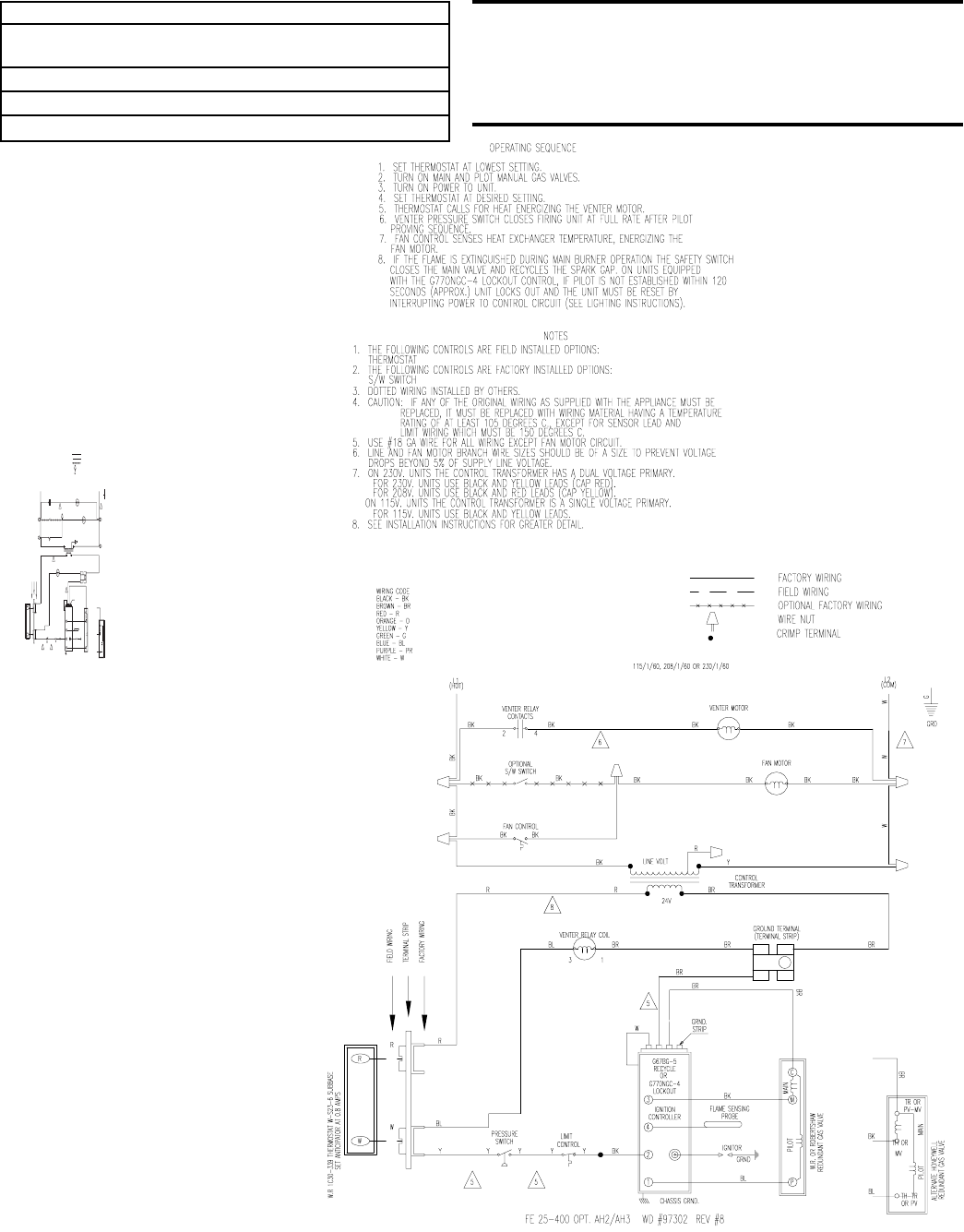

CAUTION: If any of the original wire as supplied with

the appliance must be replaced, it must be replaced with

wiring material having a temperature rating of at least

105

o

C, except for limit control and sensor lead wires

which must be 150

o

C. See Hazard Levels, page 2.

Field Control Wiring Length and Gauge

Total Wire Distance from MinimumRecommended

Length Unit to Control Wire Gauge

150' (45.7 m) 75' (22.9 m) #18 gauge

250' (76.2 m) 125' (38.1 m) #16 gauge

350' (106.7 m) 175' (53.3 m) #14 gauge

Fan-Type, Power-Vented Model

with Intermittent Spark Pilot,

Single-Stage Heating,

Natural or Propane

OPTIONAL FACTORY WIRING

FACTORY WIRING

FIELD WIRING

WIRE NUT

CRIMP TERMINAL

2 4

CONTACTS

VENTER RELAY

OPTIONAL

S/W SWITCH

FAN CONTROL

BK

BK BK

BK

BK BK

BK

L1

(HOT)

BK

R

VENTER MOTOR

BK

BR

GROUND TERMINAL

(TERMINAL STRIP)

L2

(COM)

115/1/60, 208/1/60 OR 230/1/60

31

VENTER RELAY COIL

BL BR

BR

R

SET ANTICIPATOR AT 0.8 AMPS

W.R 1C30-339 THERMOSTAT W-S23-6 SUBBASE

W

R

W

PRESSURE

SWITCH

Y YYY

LIMIT

CONTROL

Y

GRND.

RECYCLE

G67BG-5

OR

LOCKOUT

IGNITION

CHASSIS GRND.

CONTROLLER

G770NGC-4

1

3

2

4

W

PROBE

GRND

IGNITOR

STRIP

FLAME SENSING

BK

ALTERNATE HONEYWELL

REDUNDANT GAS VALVE

BL

PILOT

OR PV

TH-TR

TH OR

MV

PV-MV

TR OR

MAIN

PILOT

W.R. OR ROBERTSHAW

REDUNDANT GAS VALVE

P

MAIN

M

C

BR

BR

BL

BL

R

BK

FIELD WIRING

TERMINAL STRIP

FACTORY WIRING

OPERATING SEQUENCE

1. SET THERMOSTAT AT LOWEST SETTING.

2. TURN ON MAIN AND PLOT MANUAL GAS VALVES.

3. TURN ON POWER TO UNIT.

5. THERMOSTAT CALLS FOR HEAT ENERGIZING THE VENTER MOTOR.

6. VENTER PRESSURE SWITCH CLOSES FIRING UNIT AT FULL RATE AFTER PILOT

8. IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION THE SAFETY SWITCH

CLOSES THE MAIN VALVE AND RECYCLES THE SPARK GAP. ON UNITS EQUIPPED

WITH THE G77ONGC-4 LOCKOUT CONTROL, IF PILOT IS NOT ESTABLISHED WITHIN 120

SECONDS (APPROX.) UNIT LOCKS OUT AND THE UNIT MUST BE RESET BY

INTERRUPTING POWER TO CONTROL CIRCUIT (SEE LIGHTING INSTRUCTIONS).

NOTES

1. THE FOLLOWING CONTROLS ARE FIELD INSTALLED OPTIONS:

THERMOSTAT

2. THE FOLLOWING CONTROLS ARE FACTORY INSTALLED OPTIONS:

S/W SWITCH

3. DOTTED WIRING INSTALLED BY OTHERS.

4. CAUTION: IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THE APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE

RATING OF AT LEAST 105 DEGREES C., EXCEPT FOR SENSOR LEAD AND

LIMIT WIRING WHICH MUST BE 150 DEGREES C.

5. USE #18 GA WIRE FOR ALL WIRING EXCEPT FAN MOTOR CIRCUIT.

6. LINE AND FAN MOTOR BRANCH WIRE SIZES SHOULD BE OF A SIZE TO PREVENT VOLTAGE

DROPS BEYOND 5% OF SUPPLY LINE VOLTAGE.

8. SEE INSTALLATION INSTRUCTIONS FOR GREATER DETAIL.

WWW

BK BK

BR

BR

BK

G

GRD

4. SET THERMOSTAT AT DESIRED SETTING.

PROVING SEQUENCE.

7. FAN CONTROL SENSES HEAT EXCHANGER TEMPERATURE, ENERGIZING THE

FAN MOTOR.

CONTROL

BK

R

24V

LINE VOLT

BR

R

TRANSFORMER

Y

6

BK

FAN MOTOR

BKBK

5 5

5

FOR 208V. UNITS USE BLACK AND RED LEADS (CAP YELLOW).

ON 115V. UNITS THE CONTROL TRANSFORMER IS A SINGLE VOLTAGE PRIMARY.

7. ON 230V. UNITS THE CONTROL TRANSFORMER HAS A DUAL VOLTAGE PRIMARY.

FOR 230V. UNITS USE BLACK AND YELLOW LEADS (CAP RED).

FOR 115V. UNITS USE BLACK AND YELLOW LEADS.

FE 25-400 OPT. AH2/AH3 WD #97302 REV #8

7

WHITE - W

PURPLE - PR

BLUE - BL

GREEN - G

YELLOW - Y

ORANGE - O

RED - R

BROWN - BR

BLACK - BK

WIRING CODE

8