MAINTENANCE

OM 0400-A

28

Note: Shield bearings must be greased every 8 working hours.

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

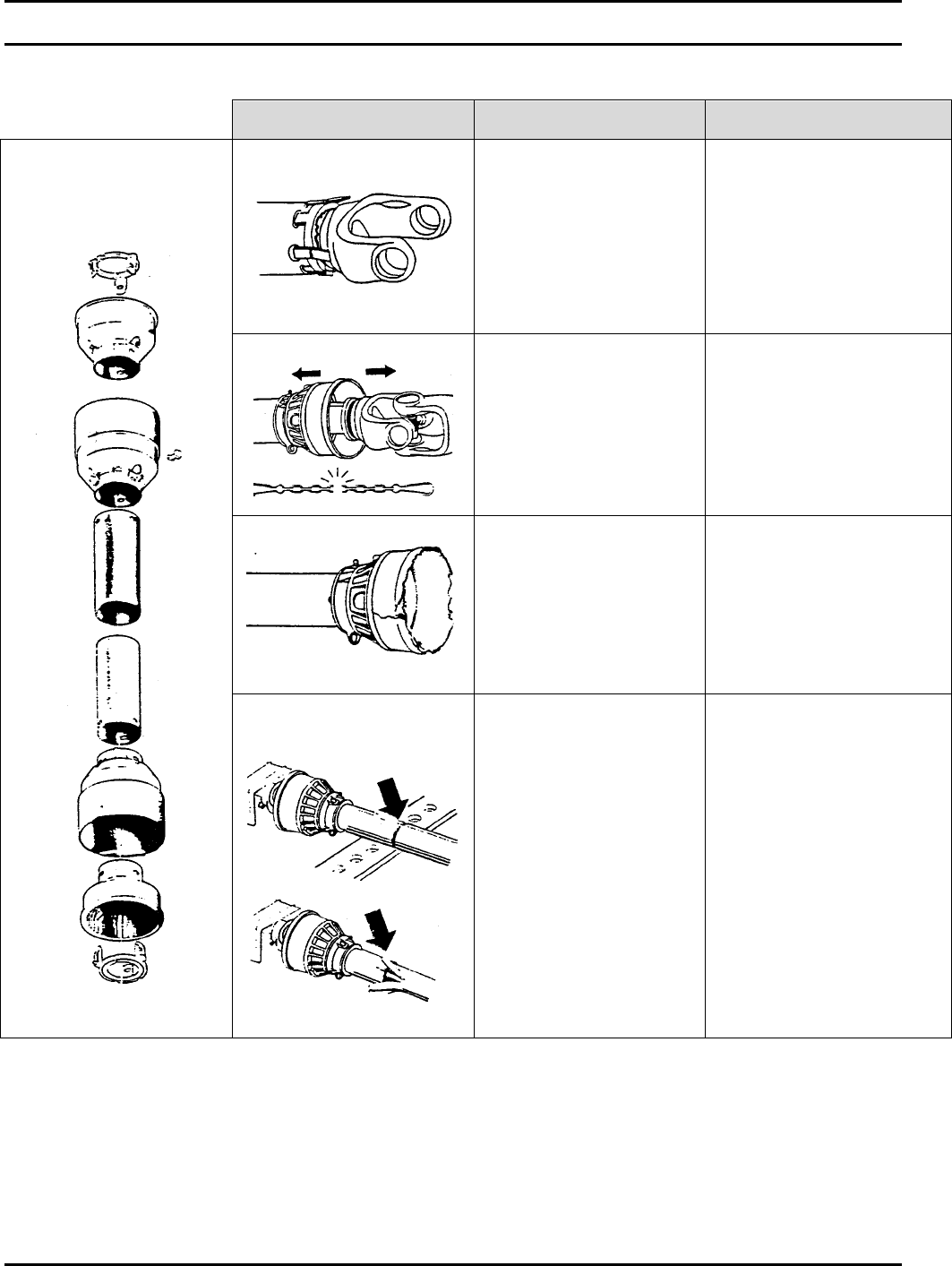

SHIELD

Excessive wear of shield

bearings.

Insufficient lubrication.

Incorrect chain mounting.

Shield interfering with

implement.

Follow lubrication instructions.

Mount chain to allow

maximum angularity.

Avoid contact of the shields

with fixed parts of the machine

or tractor.

Replace shield bearings.

Chain moving or failure.

Shield interfering with

implement.

Incorrect chain mounting.

Avoid contact of the shields

with fixed parts of the machine

or tractor.

Mount chain to allow

maximum angularity.

Replace defective parts.

Shield cone damaged.

Shield cone in contact with

components on the tractor

and/or implement.

Excessive angularity.

Eliminate interference

between Shield cones and any

part on the tractor and/or

implement.

Avoid excessive angle during

cornering or when lifting or

lowering the implement.

Replace damaged Shield

cones.

Shield tubes damaged

(deformed and split at one

side).

Shields in contact with

components on the tractor

and/or implement.

Shield tubes overlap too

short or no overlap at all

with extended driveline.

Eliminate interference

between Shield cones and

any part on the tractor and/or

implement.

Replace damaged tubes.

Adjust Shield tubes length

with longer tubes.