ASSEMBLY

OM 0400-A

15

ANGLES AT EACH END OF DRIVELINE

To avoid damages to the driveline or the

debris blower, it is recommended to always

keep tractor driveline and debris blower input

shaft parallel.

DETERMINING DRIVELINE LENGTH

IMPORTANT: Before using the equipment,

make sure the driveline is not too long. At

working position, the two half drivelines

must intersect each other sufficiently to

insure maximum efficiency but there must

not be any interference.

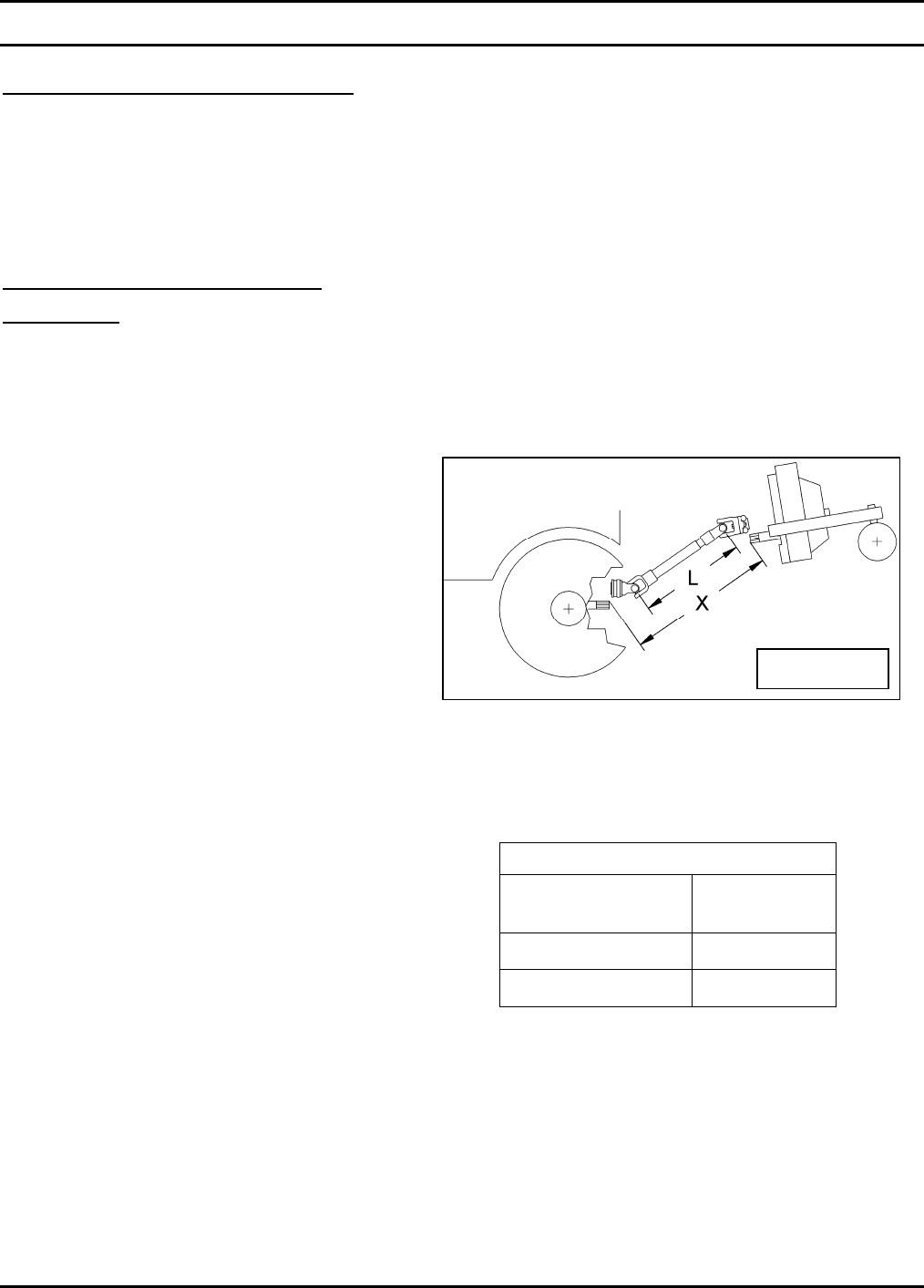

1. To determine the "L" length for your tractor

model first find the "X" factor by measuring

the horizontal distance between the end of

the tractor's drive shaft and the end of the

debris blower's driven shaft when the

debris blower is in transport position as

shown on Figure A.

2. Choose in the table below the "Y" factor

according to the tractor category and

deduct that number from "X" to determine

"L" which is the center-to-center length

between the universal joints.

L = X – Y

3 PTS HITCH

CATEGORY

Y

Cat. 1 4 1/2"

Cat. 2 5 1/2"

Figure A