MAINTENANCE

OM 0400-A

26

DRIVELINE TROUBLESHOOTING

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

QUICK-DISCONNECT YOKE

Quick-disconnect pin tight or

completely seized.

Quick-disconnect pin

damaged (broken or bent)

Quick-disconnect pin

damaged in the locking

portion.

Quick-disconnect pin dirty

(insufficient maintenance).

Quick-disconnect pin

defective (forced

engagement, incorrect

handling)

Excessive shaft length.

Axial loads too high.

Clean, oil and follow service

instructions.

Replace quick-disconnect pin.

Shorten shaft length (cut both

telescopic tubes as well as

shield and remove burrs).

Replace quick-disconnect pin.

Clean and grease telescopic

tubes, and replace both tubes,

if necessary.

Replace quick-disconnect pin.

Note: Quick-disconnect pins must be cleaned and greased every 16 hours.

AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS

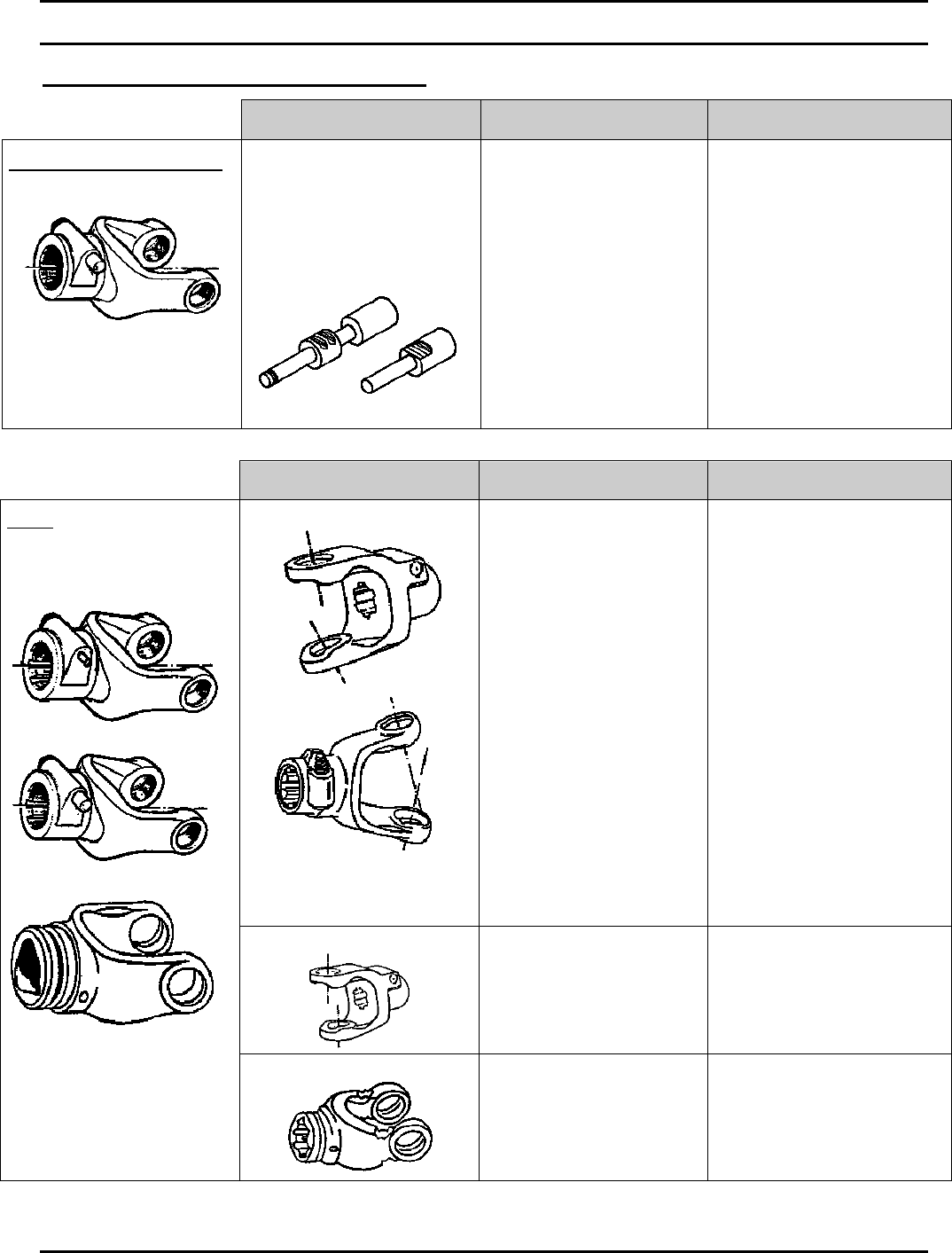

YOKE

Yoke ears deformation

Excessive shaft length.

Axial loads too high.

Excessive working angle

and torque.

Shorten shaft length (cut both

telescopic tubes as well as

shields and remove burrs).

Replace defective yokes.

Clean and grease telescopic

tubes, and replace both tubes,

if necessary.

Replace defective yokes.

Verify compatibility between

shaft and working conditions

(torque vs. angle).

Disengage tractor driveline

during cornering or when lifting

or lowering the implement.

Change to a larger driveline

size.

Replace defective yokes.

Yoke ears distorted. Overload caused by high

starting and peak torques.

Engage driveline more

carefully.

Use appropriate safety

devices.

Replace defective yokes.

Yoke ears worn or pounded.

Excessive working angle. Avoid excessive working

angle.

Disengage tractor driveline

during cornering.

Replace defective yokes.