OPERATION

OM 0400-A

21

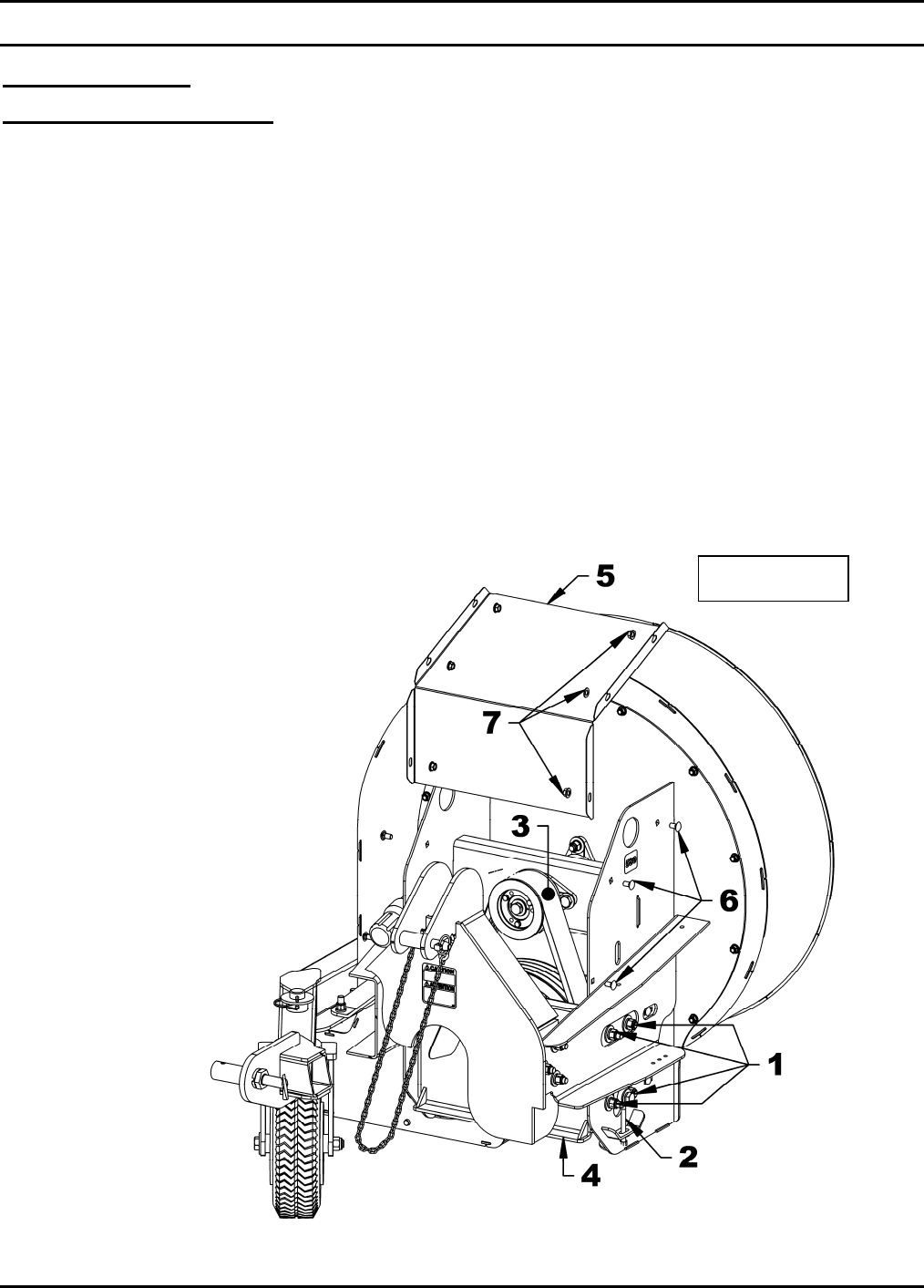

Figure 9

ADJUSTMENTS

Belt Tension Adjustment (Figure 9)

1. Remove the belt protector (item 5) by

removing the six 3/8"NC x 3/4" carriage

bolts and six serrated flange nuts (items 6-

7).

2. Loosen the eight 1/2"NC nylon insert

locknut (item 1).

3. Tighten eyebolt nuts (item 2). With a belt

tension gauge check for a 35lbs tension

and a 3/16" displacement in the center in all

belt axis (item 3).

4. Realign the driving pulley assembly (item 4)

by pressing the support against the bolted

guides. Tighten loosely the eight 1/2"NC

nylon insert locknuts (item 2) loosen

previously. With a long ruler that may cover

the distance between pulleys, check the

pulleys alignment, If alignment is good,

tighten the eight 1/2"NC nylon insert

locknuts (item 2). If not, follow next step.

5. If the belts are not well aligned, loosen the guide

nuts and the eyebolt nuts. Align the two pulleys,

slightly tighten the eight 1/2"NC nylon insert

locknuts (item 2). Press the guides against the

driving pulley assembly (item 4) and tighten guide

nuts. Redo step 2. Check the pulleys alignment

and if the driving pulley assembly is well pressed

on guides. If so, tighten firmly the eight 1/2"NC

nylon insert locknuts. If not, repeat procedure.

6. Reinstall the belt protector (item 5) with the six

3/8"NC x 3/4" carriage bolts and six serrated

flange nuts (items 6-7).