Assembly Section 2-3

ASSEMBLY

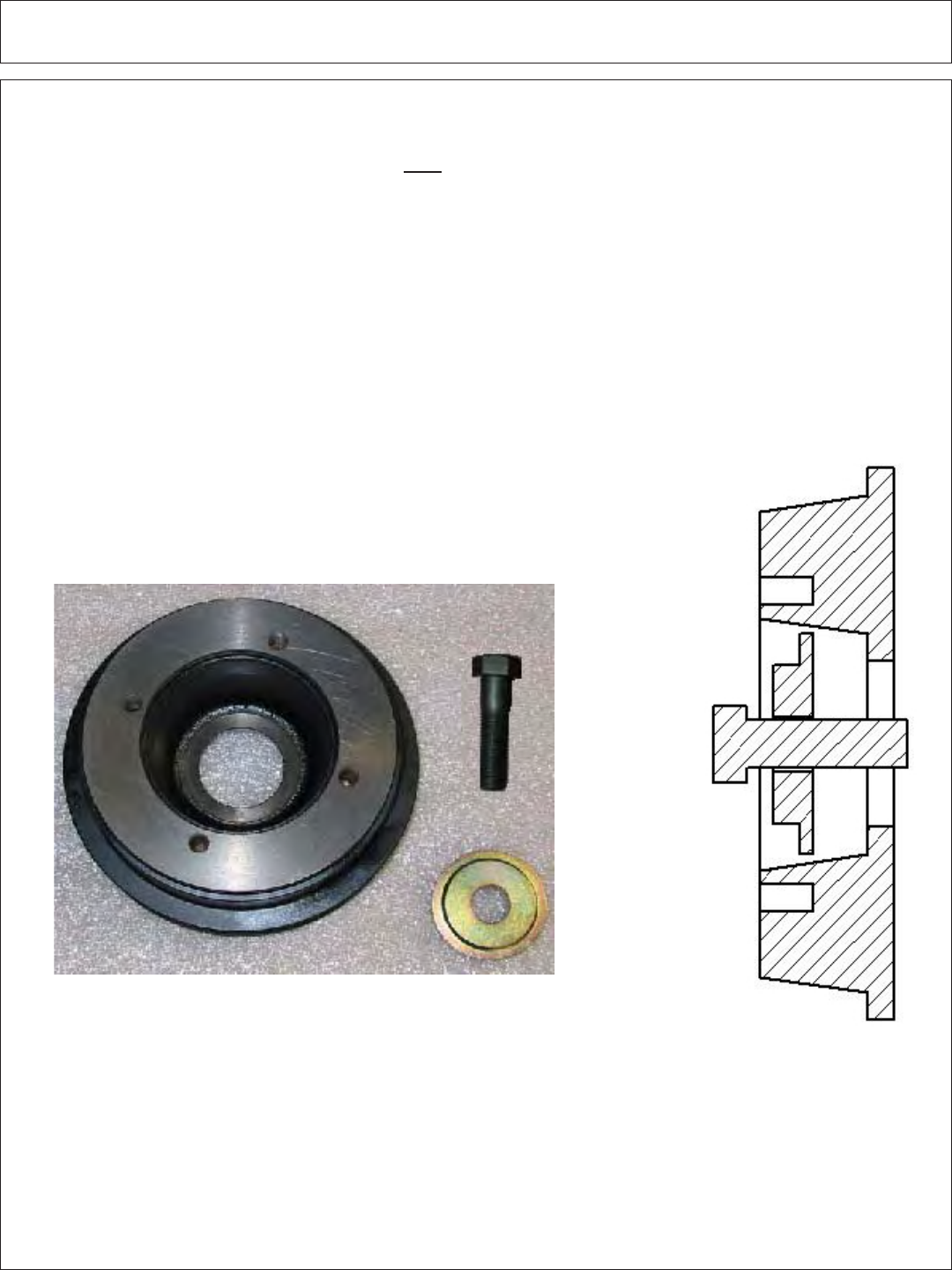

FRONT CRANKSHAFT PULLEY

Solution:

1. Clean nose of crankshaft using TY16285 clean and cure primer.

2. Apply a light 2-3 mm bead of TY15969 retaining compound around the leading edge

of the crankshaft nose.

3. Dip damper mounting caps crew in clean SAE30 engine oil (Always use a new cap

screw)

4. Position damper/pulley on the crankshaft and thread cap screw up tight (do not rely

on the cap screw to pull the pulley straight onto the taper)

5. Tighten cap screw to specification 500Nm (369lb-ft) (the engine will most likely

have to be pinned)

6. Measure run-out on the pulley, spec is 0.003” or less

PARTS REQUIRED TO PURCHASE FROM JOHN DEERE:

Pulley from JD – R516320

Washer from JD – R517237

Bolt from JD – R516648

Torque on the pulley bolt with locktite is 369 lb-ft.*

John Deere has changed to a

new tier two engine on all 6000 series tractors. With

the change, Tiger has found that the front crankshaft pulley used by JD will not allow for the

installation of a front drive system. With the change on the 6X15 and 6X20 series tractors,

you will need to order a different pulley, washer and bolt from John Deere to allow for a front

drive to be installed on your tractor.

Inspect the front pulley on your tractor to verify you have the correct pulley needed to

mount the spacer plate. If your pulley has the (4) four holes needed to mount the spacer,

your pulley is the correct one needed. If your pulley does not have the (4) four holes in the

pulley, you will need to order the correct pulley, washer and bolt from John Deere.