4

.

Tektron

ix

part

nu

m

be

r

.

Sol

de

r

i

ng

Tec

hn

i

qu

es

W

A

RN

I

N

G

To

avoid

elect

r

ic

s

h

oc

k

haza

rd

,

disconnect

the

i

n

st

rum

e

n

t

f

r

om

t

h

e

power

so

urce

befo

r

e

sol

d

e

r

i

n

g

.

T

h

e

r

elia

b

ility

a

nd

accuracy

of

t

h

is

i

n

str

u

me

n

t

can be

m

ai

n

taine

d

only

if

p

ro

p

er

sol

d

eri

ng

tec

hn

i

qu

es

a

r

e use

d

.

w

h

en

r

ep

ai

r

i

n

g

o

r

r

ep

laci

ng p

arts

.

Ge

n

e

r

al

sol

de

r

ing

tec

h

ni

ques

w

h

ic

h

apply

to

m

ai

n

te

nan

ce

of

any

pr ecisio

n

elect

r

o

n

ic

e

qu

i

p

me

n

t

sh

o

u

l

d

be

u

se

d

w

h

e

nwo

rk

i

ng

on

t

h

is inst

ru

me

n

t

.

U

se

only

60/40

rosin-core,

electronic

g

r

a

de

sol

d

e

r

.

T

he

choice

of

soldering

i

r

o

n

is

dete

rmi ned

by

t

he

r

ep

ai

r

to

b

e

m

ade

.

Wh

en

sol

d

e

r

i

ng

on

ci

r

cu

it

b

oa

rd

s

or s

m

all

wiri

n

g,

u

se

only

α

15

watt,

pencil

ty

pe

sol

d

eri

n

g

iro

n

.

Α

h

ig

h

e

r

wattage

sol

de

r

i

ng

iro

n

can

cause

t

he

etc

h

e

d

circ

u

it

wi

r

i

ng

to

se

pa

r

ate

fr

om

t

he

b

oard

base

m

ater

i

al

and

melt

t

he

i

nsu

latio

n

f

r

o

m

small

wi

r

i

ng

.

Always

k

ee

p

t

h

e

sol

d

e

r

i

n

g

i

r

o

n

ti

p

p

r

op

e

r

ly

ti

nn

ed

to

en

s

ur

ethe

best

heat

t

r

an

sfe

r

to

t

he

sol

de

r

j

oi

n

t

.

A

pp

ly

only e

n

o

ughh

eat to

r

e

m

ove

t

he

com

pon

ent

o

r

to

m

ak

eα

goo

d

sol

d

e

r

j

oi

n

t

.

To

p

r

otect

heat

se

n

sitive

co

mp

o

nen

ts,

h

ol

d

t

he

com

po

nent

lea

d

wit

h

α

p

ai

r

of

lo

n

g-n

ose

p

liers

betwee

n

t

he

co

mp

o

n

e

n

t

bo

dya

nd

t

he

sol

de

r j

oi

n

t

.

U

se

α

sol

d

er

r

e

m

ovi

n

g

wic

k

to

r

emove

excess

sol

d

er

f r

o

m

co

n

nectio

ns or to clea

n

ci

r

cuit

b

oa

rd

pad

s

.

Se

m

i

conductors

To

re

m

ove

i

n

-li

n

e

i

n

tegrate

d

circ

u

its

u

se an

ext

r

acti

ng

tool

.

T

h

is

tool

is

availa

b

le

f

r

o

m

Te

k

tro

n

ix,

Inc

. ;

ord

e

r

Tekt

r

o

n

ix

P

art

No

.

003-0619-00

.

If

an

extracti

ng

tool

is

n

ot

availa

b

le,

use

ca

r

eto

avoi

dd

amagi

n

g

t

h

e

p

i

ns

.

Pull

slowly

a

nd

eve

n

ly

on

b

ot

h

e

nd

s

of

t

h

e

i

n

teg

r

ate

d

circ

u

it

.

Try

to

avoi

dd

ise

n

gagi

ng o

n

e

e

nd

b

efor

e

t

he

other

e

nd

.

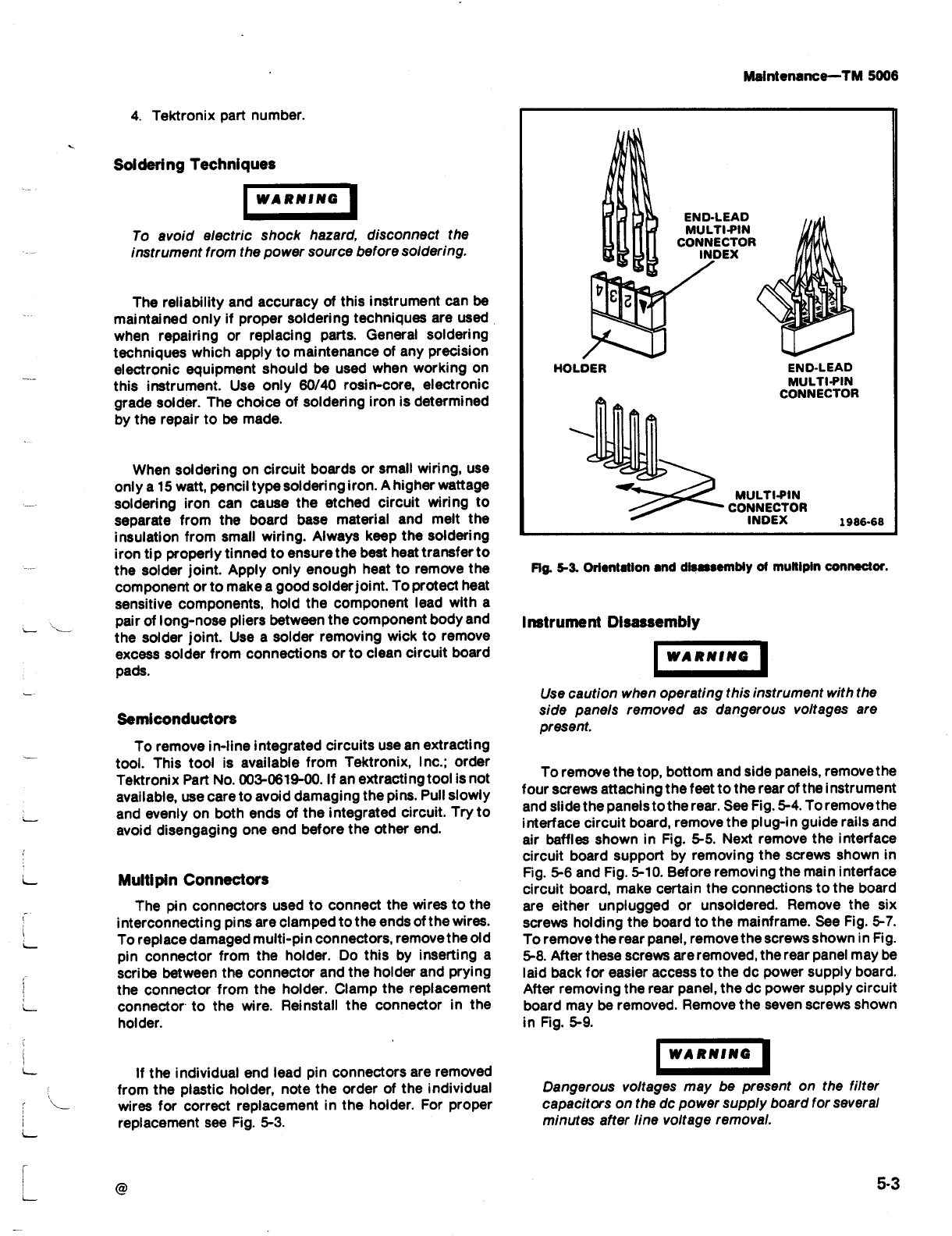

M

u

lti

p

i

n

Co

nn

ectors

T

h

e

pin

conn

ectors

u

se

d

to

co

nn

ect

t

he

wires

to

t

he

interconnecting p

i

n

sa

r

e

cla

mp

e

dto

t

he e

nd

s

of

t

h

e

wires

.

To

r

e

p

lace

d

amage

d

m

ulti-

p

i

n

conn

ectors,

r

e

m

ovethe

ol

d

p

i

n co

nn

ecto

r

from

t

he h

ol

de

r

.

Do

t

h

is

b

y

i

n

serti

ng α

sc

r

i

be

betwee

n the

conn

ector

a

nd

t

he

h

ol

d

e

r

a

nd

pr

yi

n

g

t

he

connector

f

r

om

t

h

e

h

ol

d

e

r

.

Cla

mp

t

he

r

ep

lace

m

en

t

co

nn

ector

to

t

he

wi

r

e

.

R

ei

n

stall

t

h

e

conn

ecto

r

in

t

he

h

ol

de

r

.

If

the

i

nd

ivi

du

al

e

nd

lea

dp

i

n

con

necto

r

s

a

r

e

r

emove

d

f

r

o

m

t

he p

lastic

h

ol

de

r

,

n

ote

t

he

order

of

t

h

e

i

nd

ivi

d

ual

wi

r

es

fo

r

correct

r

e

p

lace

m

en

t

i

n

t

h

e h

ol

d

e

r

.

F

o

r

pr

ope

r

r

e

p

laceme

n

t

see

F

ig

.

5-3

.

I

n

strument

D

isassem

b

ly

I

WARNING

WARNING

M

a

i

n

te

n

ance-

ΤΜ

5006

H

O

LD

ER

EN

D-

LE

AD

MUL

TI-PIN

CO

NNECTO

R

EN

D-

LE

AD

MUL

TI-PIN

CO

NNECTO

R

IN

D

E

X

MUL

TI-PIN

CO

NNECTO

R

IN

D

E

X

1986-68

Fig

.

5-3

.

Orientation

a

nd d

isasse

mb

ly

of

mu

ltip

in

connector

.

U

se

cautio

n

w

h

en

o

p

e

r

ati

n

g

t

h

is

inst

ru

me

n

t

wit

h

t

h

e

si

d

e pa

n

els

r

e

m

ove

d as d

a

n

ge

r

o

u

s

voltages

a

r

e

pr

ese

n

t

.

To

r

e

m

ove

t

he

to

p

,

b

ottom

a

nd

si

d

e

p

a

n

els,

r

emove

t

he

fo

u

r

sc

r

ews

attac

h

i

n

g

t

he

feet

to

t

he

r

ea

r

of

t

he

i

n

st

ru

me

n

t

a

nd

slide

t

he

pa

n

els

to

t

he

r

ea

r

.

See

F

ig

.

5-4

.

To

remove

t

h

e

interface

ci

r

cu

it

b

oar

d

,

r

e

m

ove

t

h

e p

l

u

g-i

n

gui

de

r

ails

a

nd

air

baffles

s

h

ow

n

in

F

ig

.

5-5

.

N

ext

r

emove

t

h

e

interface

ci

r

cu

it

b

oa

rd su

pp

ort

b

y

r

e

m

ovi

ng

t

h

e

sc

r

ews

s

h

ow

n

in

Fig

.

5-6 a

nd

F

ig

.

5-10

.

B

efo

r

e

r

e

m

ovi

ng

t

h

e

mai

n

interface

circ

u

it

b

oa

rd,

m

a

k

e

certai

n

t

he

co

nn

ectio

n

sto

t

h

e b

oar

d

a

r

e

eit

he

r

unp

l

u

gge

d

o

r

un

sol

de

r

ed

.

Re

m

ove

t

he

six

screws

h

ol

d

i

n

g

t

h

e

boa

rd to

t

he

m

ai

n

fra

m

e

.

See

F

ig

.

5-7

.

To

r

e

m

ove

t

h

e

r

earpa

n

el,

r

emovet

he

screws

sh

ow

n

in

F

ig

.

5-8

.

Afte

r

t

h

ese

screws

are

r

e

m

ove

d

, t

he

rear

p

a

n

el

may

b

e

laid

back fo

r

easie

r

access

to

t

h

e

d

o

powe

r

s

upp

ly

b

oa

rd

.

After

re

m

ovi

n

g

t

he

r

ea

r

pan

el,

t

h

e

do

power

s

upp

ly

circ

u

it

b

oa

rd

m

ay

b

e

remove

d

.

R

emove

t

h

e seve

n

sc

r

ews

sh

ow

n

in

Fig

.

5-9

.

Da

n

gero

us

voltages

may

b

e

p

r

ese

n

t

on

t

h

e

filte

r

ca

p

acito

rs

on

th

e

d

o

p

owe

r

s

upp

ly

boa

rd

fo

r

seve

r

al

minutes

afte

r

line

voltage

r

emoval

.

5-3