28 Assembly

15914 (Rev. 5/11/2007)

ASSEMBLY

DEALER SET-UP INSTRUCTIONS

These instructions are for the assembly of the MD80

and D80. Many of the procedures apply to both units.

When an instruction applies to a specific unit, the sec-

tion heading will indicate which unit.

Assembly of this cutter is the responsibility of the

WOODS dealer. It should be delivered to the owner

completely assembled, lubricated and adjusted for nor-

mal cutting conditions.

Complete check lists when assembly is complete.

The cutter is shipped partially assembled. Assembly

will be easier if components are aligned and loosely

assembled before tightening hardware. Recommended

torque values for hardware are located on page 57.

Select a suitable working area. Open parts boxes and

lay out parts and hardware to make location easy.

Refer to illustrations, accompanying text, parts lists and

exploded view drawings.

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

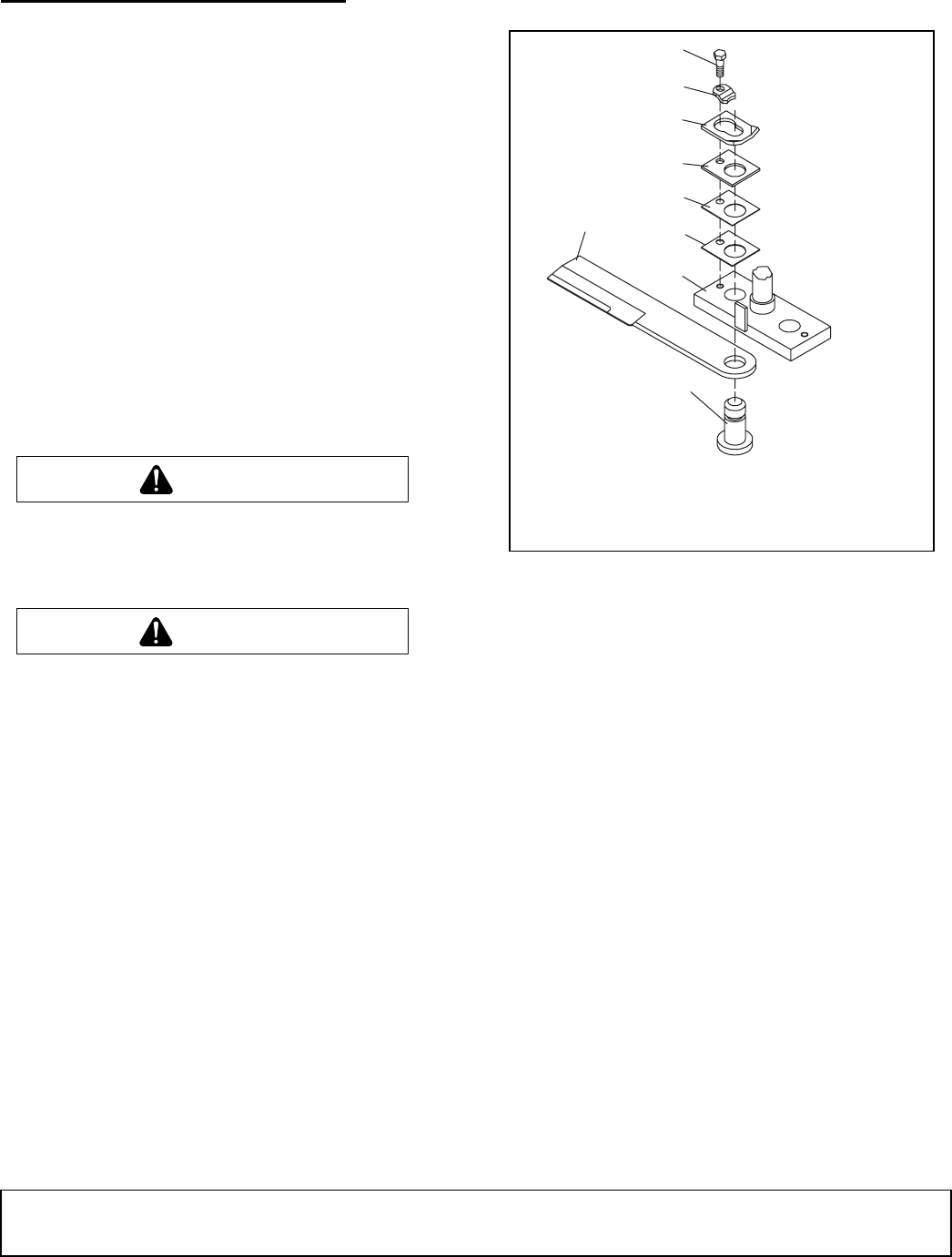

Blade Installation

Figure 20. Blade Installation

Either place cutter on stands or hang to permit access

to both top and bottom. Make sure cutter is secured to

prevent it from falling.

Liberally coat blade pin and crossbar hole with Never-

Seez® or equivalent. Make sure blade is offset away

from deck and cutting edge is positioned for counter-

clockwise rotation as viewed from top of deck.

Install blade pin (9) up through blade (8) then through

hole in crossbar and push firmly against crossbar (7).

Install as many spacers (4, 5 or 6) as possible and still

be able to slide keyhole plate (3), with ears up as

shown, into blade pin groove. Place blade pin clip (2)

over keyhole plate and into blade pin groove. Secure

with bolt (1). Repeat for opposite blade.

Blade should be snug but swivel on pin without exces-

sive force. Retain any spacers not used in installation

for use when blade wears or on future installations.

Distribution Baffle Installation

A distribution baffle is supplied. It is recommended

when mowing grass and weeds. It should not be used

when operating cutter in heavy brush.

WARNING

CAUTION

CAUTION

6. 20 GA Spacer

7. Crossbar

8. Blade

9. Blade pin

1. Bolt

2. Blade pin clip

3. Keyhole plate

4. Spacer

5. 18 GA Spacer

9

8

7

6

5

4

3

2

1

CD3818