20 Owner Service

15914 (Rev. 3/23/2007)

NOTICE

■ If blade pin is seized in crossbar and extreme

force will be required to remove it, support cross-

bar from below to prevent damage to spindle.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

Blade Installation

Always replace both blades at the same time to main-

tain balance.

Liberally coat blade pin and crossbar hole with Never-

Seez® or equivalent. Make sure blade is offset away

from deck and cutting edge is positioned for counter-

clockwise rotation.

Install blade pin (9) up through blade (8) then through

hole in crossbar and push firmly against crossbar (7).

Install as many spacers (4, 5 or 6) as possible and still

be able to slide keyhole plate (3), with ears up as

shown, into blade pin groove. Place blade pin clip (2)

over keyhole plate and into blade pin groove. Secure

with bolt (1). Repeat for opposite blade. See Figure 7.

Blade should be snug but swivel on pin without exces-

sive force. Retain any spacers not used in installation

for use when blade wears or on future installations.

Blade Sharpening

Always sharpen both blades at the same time to main-

tain balance. Follow original sharpening pattern. Do not

sharpen blade to a razor edge. Leave from a 1/16" to

1/8" blunt edge. Do not sharpen back side of blade.

Belt Installation

One of the major causes of belt failure is improper

installation.

Before new belts are installed, check pulley shafts and

bearings for wear. Check pulley grooves for cleanliness

and wear. Be sure they turn freely and with only slight

wobble. If grooves require cleaning, moisten a cloth

with a non-flammable, non-toxic degreasing agent or

commercial detergent and water.

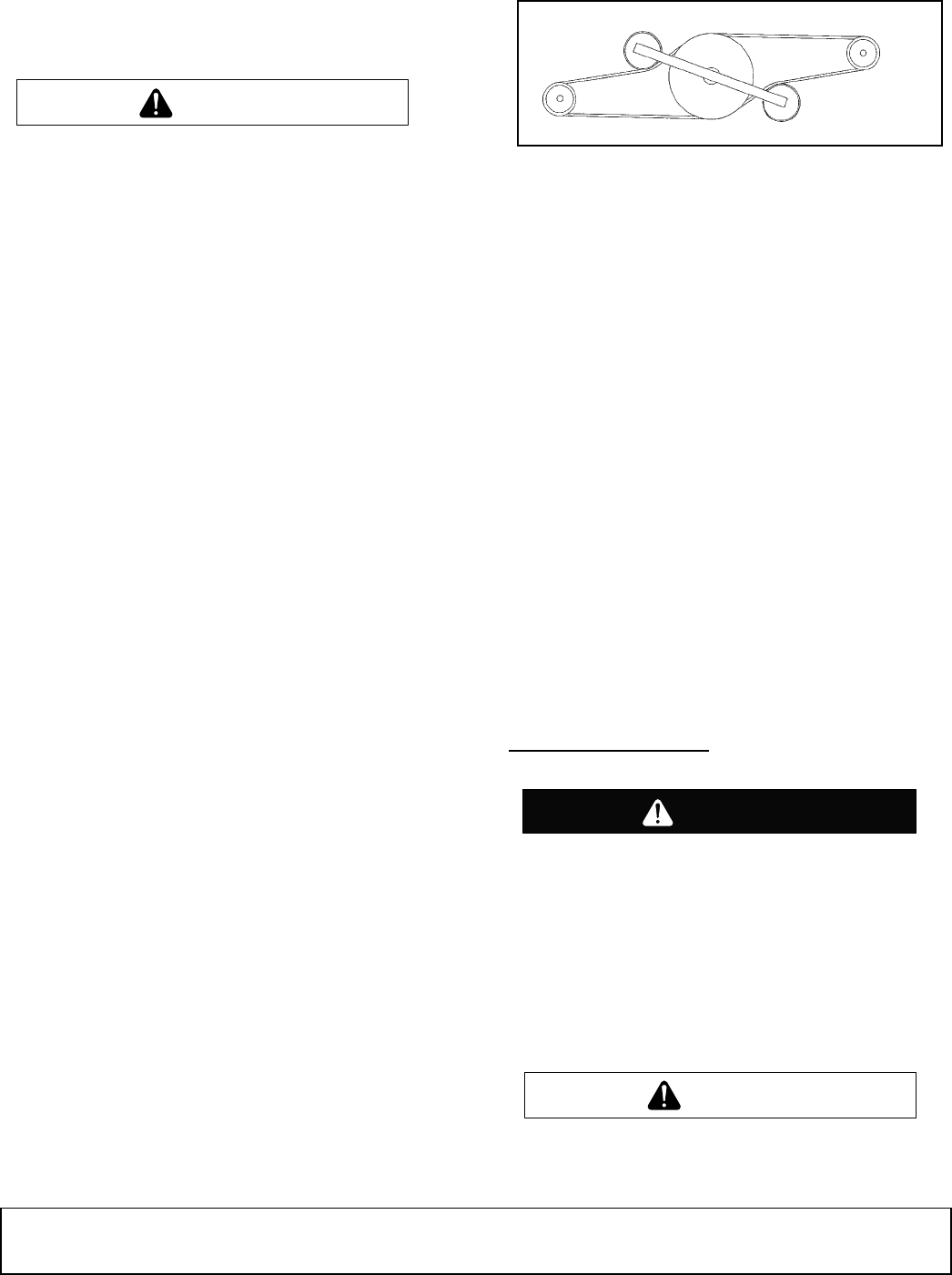

Figure 9. Belt Routing

Avoid excessive force during installation. Do not use

tools to pry belt into pulley groove. Do not roll belt over

pulleys to install. This can cause hidden damage and

premature belt failure. Always loosen idlers when

installing belts.

The drive on this cutter uses three belts. They are a

matched set and must be replaced as such.

Remove belt shields.

Loosen nut on idler adjustment rod (located on right

side of gearbox stand) as loose as possible.

Remove old belts and install new ones. Tighten nut on

idler adjustment rod. Belts should be very tight.

NOTICE

■ Check tension on new belts every half hour the

first four hours of operation and then every eight

hours.

CHAIN SHIELDING

Full chain shielding, designed to reduce the

possibility of thrown objects, must be installed

when operating in populated areas or other areas

where thrown objects could injure people or dam-

age property. If this machine is not equipped with

full chain shielding, operation must be stopped

when anyone comes within 300 feet.

Inspect chain, rubber, or steel band shielding

before each use. Replace if damaged.

CAUTION

DB967

DANGER

W

W

ARNING

ARNING