24 Dealer Service

15914 (Rev. 5/11/2007)

Proper bearing adjustment is essential to good bearing

life. Do not leave bearing adjusted too tightly. Bearings

should turn freely without any noticeable end play.

When the bearings are adjusted, coat area of spindle

housing where seal seats with Permatex and press

seal (4) (with spring-loaded lip up) into housing using

care to prevent seal cage distortion.

When the bearings are adjusted, tighten nut against

sleeve and bearing (5). Insert brass plug (2) into hole in

nut then tighten set screw (3) against brass plug (2).

Grease spindle through grease fitting (8) until a small

amount of grease escapes seal.

Install spindle on unit.

Figure 11. Blade Spindle Assembly

SHIELD BEARING SERVICE

Figure 12. Shield Bearing Service

Remove shield bearings (1) by lifting up and pulling

them out of the driveline groove.

When installing them, smear grease in the driveline

groove and install all four bearings into the groove

clockwise as shown in Figure 12.

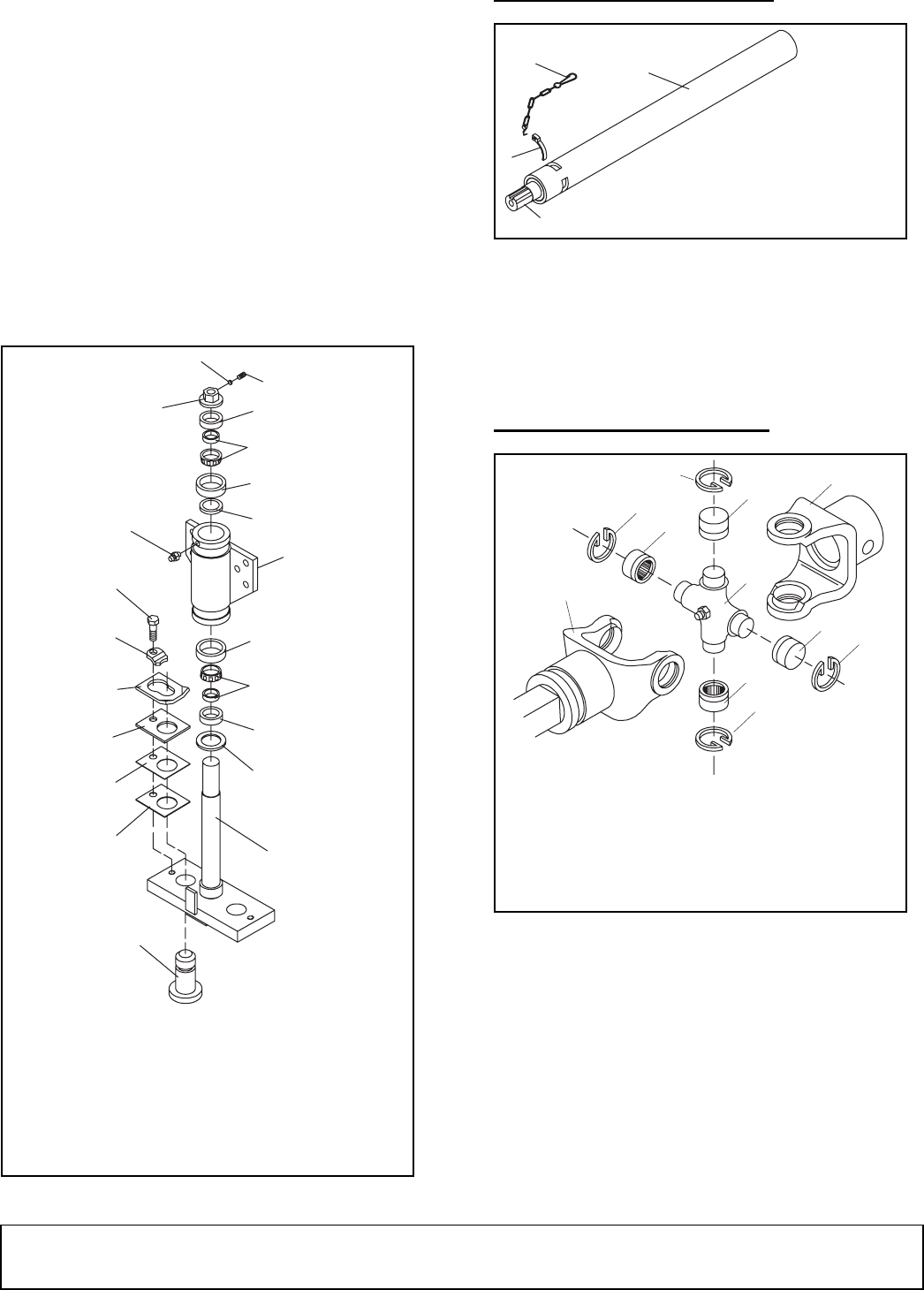

UNIVERSAL JOINT REPAIR

Figure 13. U-Joint Exploded View

U-Joint Disassembly

1. Remove snap rings from inside of yokes in four

locations as shown in Figure 14.

1. Flanged nut

2. Brass plug

3. Set screw

4. Oil seal

5. Bearing cone and

sleeve

6. Bearing cup

7. Washer

8. Grease fitting

9. Washer

17

16

15

14

13

12

11

10

9

4

5

6

8

7

6

5

4

3

2

1

CD3829

18

10. Crossbar

11. Blade pin

12. 18 Gauge shim

13. 20 Gauge shim

14. Spacer

15. Keyhole plate

16. Blade pin clip

17. Bolt

18. Spindle housing

4

3

2

1

CD3939

1. Shield bearing

2. Tether chain

3. Plastic shield

4. Tubular drive shaft

CD1645A

3

3

3

3

2

2

2

2

4

1

1

1.Yoke

2.Snap ring

3.Cup and bearings

4.Cross

5.Yoke