25

Section 5: Maintenance & Lubrication

2/02/08

RC5014 (540 RPM) and RCM5014 (1000 RPM) Rotary Cutters 330-117M

Land Pride

Table of Contents

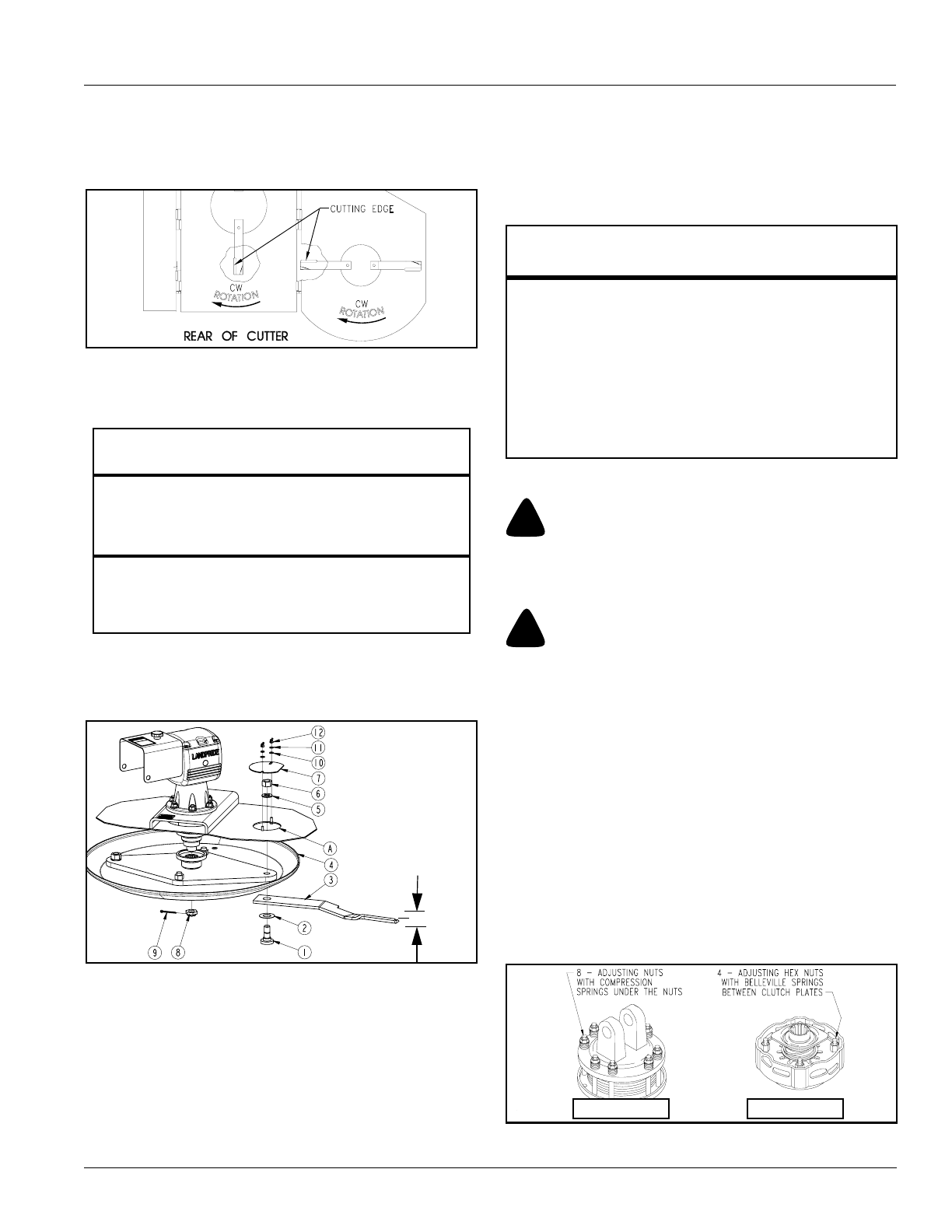

6. Refer to Figure 5-2: Carefully check cutting edges of

blades in relation to blade carrier rotation to ensure

correct blade placement. Cutter blades must be

installed with cutting edge leading in rotation. Airfoil

(lift) must be oriented towards the top of the deck.

Blade Rotation

Figure 5-2

Refer to Figure 5-3:

7. Start by assembling blades without shim (#2). Insert

blade bolt (#1) through blade (#3), dish pan (#4) and

flat washer (#5). Temporarily secure blade with a used

1 1/8"-12 nut. Draw nut up snug. Do not tighten.

Cutter Blade Assembly

Figure 5-3

8. Check blade deflection. If deflection is greater than

3/4", remove blade bolt and reassemble as before

except include shim (#2) when reassembling. Select

shim thickness based on deflection. The greater the

deflection, the thicker the shim.

9. Once blade deflection is correct, replace used nut

with new locknut (#6) and torque to 450 ft. lbs.

IMPORTANT: Examine blade bolts (#1) and

washers (#5) for excessive wear and replace if worn.

IMPORTANT: Shim (#2) may or may not be

required. If blade deflection is less than 3/4" without

a shim, then the shim is not used. However, a shim

is required if blade deflection is greater than 3/4".

IMPORTANT: Locknuts can loose their ability to

lock properly once removed. Therefore, always use

a used blade nut or plain nut in steps 7 & 8 and then

replace used nut with new locknut in step 9.

3/4" maximum

blade deflection

when blade

bolts are tight

26675

10. If replacing dishpan (#4), nut (#8) on gearbox output

shaft should be torqued to 550 ft-lbs. minimum and

secured with cotter pin (#9) with both legs bent

opposite directions around the nut.

11. Replace access cover (#7) with flat washers (#10),

lock washers (#11) and wing nuts (#12).

12. Reconnect main driveline to tractor PTO shaft.

Drivelines With Slip Clutches

!

CAUTION

Engage parking brake, disengage PTO, shut off tractor, and

remove key before working on or around the driveline and/or

slip clutch.

!

CAUTION

Slip clutches that have been in use or have been slipped for only

two or three seconds during run-in may be too hot to touch.

Allow a hot clutch to cool before working on it.

Cutter drive components are protected from shock loads

by a friction slip clutch. The clutch must be capable of

slippage during operation to protect the gearbox,

driveline and other drive train parts.

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity to remove

any oxidation that may have accumulated on the friction

surfaces. Repeat “run-in” instructions at the beginning of

each season and when moisture and/or condensation

seizes the inner friction plates.

Refer to Figure 5-4 to determine which friction clutch

your cutter has. Follow run-In, disassembly and

assembly instructions for your specific clutch.

Clutch Types

Figure 5-4

Land Pride Cutter Blade Parts

Item Part No. Part Description

318-586A BLADE BOLT KIT (Item No’s 1, 2, 5 & 6)

)

1 802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

2 312-075D BLADE SPACER 16 GA. (.06")

2 312-082D BLADE SPACER 18 GA. (.062")

2 312-089D BLADE SPACER 20 GA. (.036")

2 312-808D BLADE SPACER 24 GA. (.024")

3 820-249C CUTTER BLADE 1/2 x 4 x 23 CW

4 318-399D LARGE ROUND DISHPAN .19

5 804-147C WASHER FLAT 1 HARD ASTMF436

6 803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

Type A Clutch Type B Clutch

23560