12

Section 1: Assembly and Set-up

RC5014 (540 RPM) and RCM5014 (1000 RPM) Rotary Cutters 330-117M 2/02/08

Land Pride

Table of Contents

Hitch Types

The cutter is factory supplied with a standard clevis hitch.

The optional pintle hitch is also available. See your

nearest Land Pride dealer should you want to change

your hitch set-up.

Standard Clevis Hitch

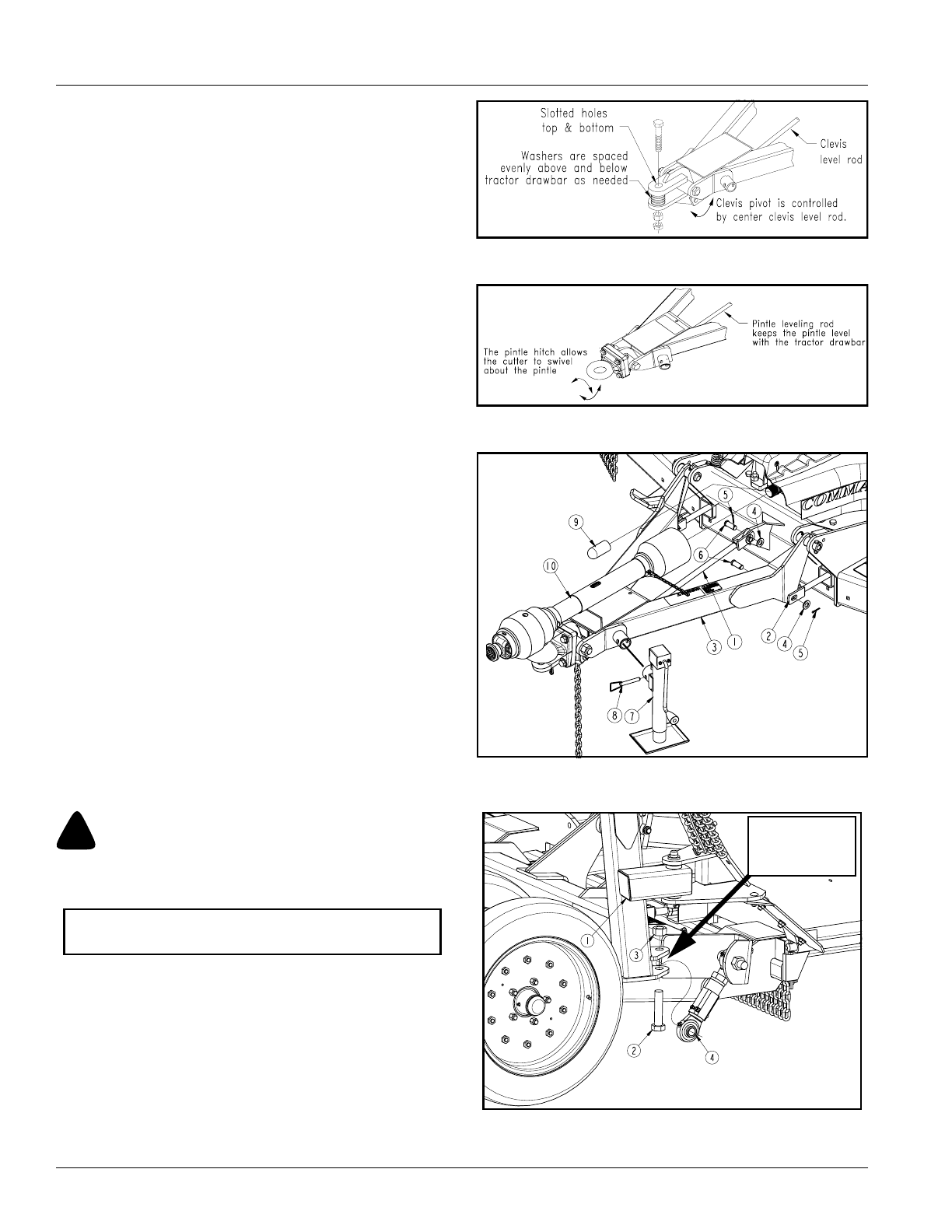

Refer to Figure 1-2:

A level rod attached to the underside of the clevis keeps

the clevis parallel with the tractor drawbar at all cutting

heights. Cutter rotation about the tractor drawbar is

limited to slots located in the clevis’ upper and lower

plates. Hitch should be secured to the tractor tongue with

bolt, washers and nuts to prevent spreading of clevis.

Pintle Hitch (Optional)

Refer to Figure 1-3:

A pintle leveling rod attached to the underside of the

pintle keeps the pintle parallel with the tractor drawbar at

all cutting heights. Cutter rotation about the tractor

drawbar is limited to movement about the pintle

connection.

Hitch Assembly

Refer to Figure 1-4:

1. Install clevis rod (#1) to deck center lug using

3/4” x 1 1/2” clevis pin (#6), 3/4” flat washer (#4) and

5/32” x 1 1/4” cotter pin (#5).

2. Install left and right leveling rods (#2) to hitch

frame (#3) with 3/4” x 1 1/2” clevis pins (#6), 3/4” flat

washes (#4) and 5/32” x 1 1/4” cotter pins (#5). Final

adjustment should be made when the cutter is

attached to the tractor.

3. Install parking jack (#7) to hitch frame (#3) and

secure with attached pin (#8). Adjust parking jack to

preferred drawbar height.

Wing Axle Assembly

Refer to Figure 1-5:

!

WARNING

Connect turnbuckle #4 between wing axle flanges before

lowering wing. Otherwise, personal injury and/or damage to

turnbuckle can occur.

Wing axles are secured folded backing for shipping

purposes.

1. Remove ties securing left and right wing axles (#1)

and rotate axles to install turnbuckles (#4).

2. Remove locknuts (#3) and cap screws (#2).

3. Attach left and right turnbuckles (#4) to wing axles

with existing 1”-8 Gr8 cap screws (#2) and 1” lock

nuts (#3). Make sure grease zerks are facing up

when wings are folded down.

4. Tighten locknuts (#3) to the correct torque.

NOTE: Do not tighten hardware until wing axle

assembly is complete.

Standard Clevis Hitch

Figure 1-2

Pintle Hitch

Figure 1-3

Hitch & Driveline Assembly

Figure 1-4

Wing Axle - Turnbuckle Assembly

Figure 1-5

22268

24730

24847

15336

Turnbuckle (#4)

to be secured

between the two

flanges.