SECTION 4.4

DIAGNOSTIC TESTS

PART 4

DC CONTROL

3. Attach the spark plug lead to the spark tester terminal.

4. Crank the engine while observing the spark tester. If

spark jumps the tester gap, you may assume the engine

ignition system is operating satisfactorily.

NOTE:

The

engine

flywheel

must

rotate

at

350

rpm

(or

higher)

to

obtain

a

good

test

of

the

solid

state

ignition

system.

To determine if an engine miss is ignition related,

connect the spark tester in series with the spark plug

wire and the spark plug (Figure 21). Then, crank and

start the engine. A spark miss will be readily

apparent. If spark jumps the spark tester gap

regularly but the engine miss continues, the problem

is in the spark plug or in the fuel system.

NOTE:

A

sheared

flywheel

key

may

change

ignition

timing

but

sparking

will

still

occur

across

the

spark

tester

gap.

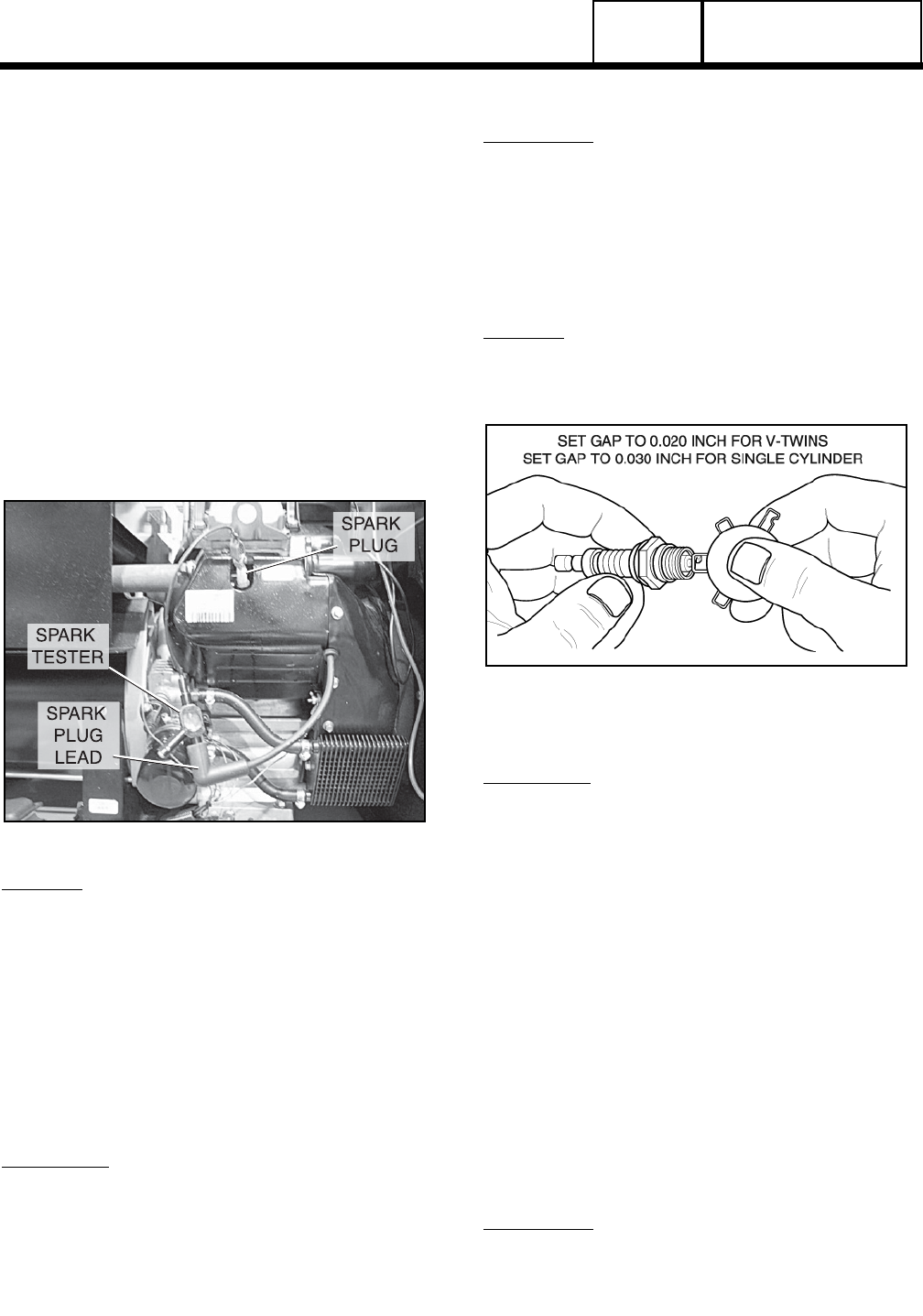

Figure 21. Checking Engine Miss

RESULTS:

1. If no spark or very weak spark occurs, go to Test 58.

2. If sparking occurs but engine still won't start, go to

Test 56.

3. When checking for engine miss, if sparking occurs at

regular intervals but engine miss continues, go to Test 16.

4. When checking for engine miss, if a spark miss is

readily apparent, go to Test 59.

TEST

56

-

CHECK

SPARK

PLUGS

DISCUSSION:

If the engine will not start and Test 55 indicated good

ignition spark, perhaps the spark plug(s) are fouled or

otherwise damaged. Engine miss may also be caused

by defective spark plug(s).

PROCEDURE:

1. Remove spark plugs and clean with a penknife or use a

wire brush and solvent.

2. Replace any spark plug having burned electrodes or

cracked porcelain.

3. Set gap on new or used spark plugs to 0.030 inch for

single cylinder engines and 0.020 inch for v-twin engines.

RESULTS:

1. Clean, re-gap or replace spark plugs as necessary.

2. If spark plugs are good, go to Test 62.

Figure 22. Checking Spark Plug Gap

TEST

57-

CHECK

ENGINE

COMPRESSION

DISCUSSION:

Lost or reduced engine compression can result in (a)

failure of the engine to start, or (b) rough operation.

One or more of the following will usually cause loss of

compression:

❏Blown or leaking cylinder head gasket.

❏Improperly seated or sticking-valves.

❏Worn Piston rings or cylinder. (This will also result

in high oil consumption).

NOTE:

For

the

single

cylinder

engine,

the

minimum

allowable

compression

pressure

for

a

cold

engine

is

60

psi.

NOTE:

It

is

extremely

difficult

to

obtain

an

accurate

compression

reading

without

special

equipment.

For

that

reason,

compression

values

are

not

published

for

the

V-TTwin

engine.

Testing

has

proven

that

an

accurate

compression

indication

can

be

obtained

using

the

following

method.

PROCEDURE:

Page 4.4-12