SECTION 4.4

DIAGNOSTIC TESTS

PART 4

TEST

52

-

TEST

FUEL

SOLENOID

Note:

This

test

is

for

fuel

regulators

equipped

with

idle

circuit

port

only.

See

Figure

16.

These

units

have

an

additional

1/4”

fuel

hose.

DISCUSSION:

When the Fuel Solenoid (FS) is energized, gas

pressure is available internally to the on demand Fuel

Regulator. Gas pressure will then be available to the

idle circuit port of the Fuel Regulator.

PROCEDURE:

1. Disconnect Wire 56 from the starter contactor relay

(SCR). This will disable the unit from cranking. For

single cylinder units, disconnect from the starter

contactor (SC) and isolate it from ground.

2. Remove the fuel hose from the idle circuit port barbed

fitting.

3. Attach a manometer (Generac P/N 0C7977) to the idle

circuit port barbed fitting.

4. Set the AUTO-OFF-MANUAL switch to MANUAL. The

engine will not crank, but gas pressure should be

observed on the manometer at 11”-14” of water column.

5. Set the AUTO-OFF-MANUAL switch to OFF. Remove

the manometer. Re-attach the fuel hose to the idle circuit

port barbed fitting. Re-connect Wire 56 to the starter

contactor relay or starter contactor.

RESULTS:

1. If gas pressure was measured, proceed to Test 55.

2. If gas pressure was NOT measured, replace the fuel

solenoid (FS).

TEST

53

-

CHECK

CIRCUIT

BOARD

WIRE

14

OUTPUT

DISCUSSION:

During any cranking action, the circuit board’s crank

relay (K1) and run relay (K2) both energize

simultaneously. When the run relay energizes, its

contacts close and 12 volts DC is delivered to Wire 14

and to a fuel solenoid. The solenoid energizes open

to allow fuel flow to the engine. This test will

determine if the circuit board is working properly.

PROCEDURE:

1. Set the AUTO-OFF-MANUAL switch to OFF.

2. Connect the positive (+) test lead of a DC voltmeter (or

VOM) into Pin 7 (Wire 14) of the circuit board connector

J1. Connect the common (-) test lead to frame ground.

3. While observing the meter, set the AUTO-OFF-MANUAL

switch to MANUAL.

a.The circuit board’s crank and run relays should

energize and the engine should crank and start.

b.The meter should indicate battery voltage.

c. If battery voltage is indicated, proceed to Step 4.

If battery voltage is NOT indicated, proceed to

Test 53 results.

4. Disconnect Wire 14 at the Fuel Solenoid (FS).

a.Connect the positive (+) test lead to Wire 14. Connect

the negative test lead to a clean frame ground. Set

the AUTO-OFF-MANUAL switch to MANUAL. Battery

voltage should be measured. If battery voltage is

indicated, proceed to Step 5.

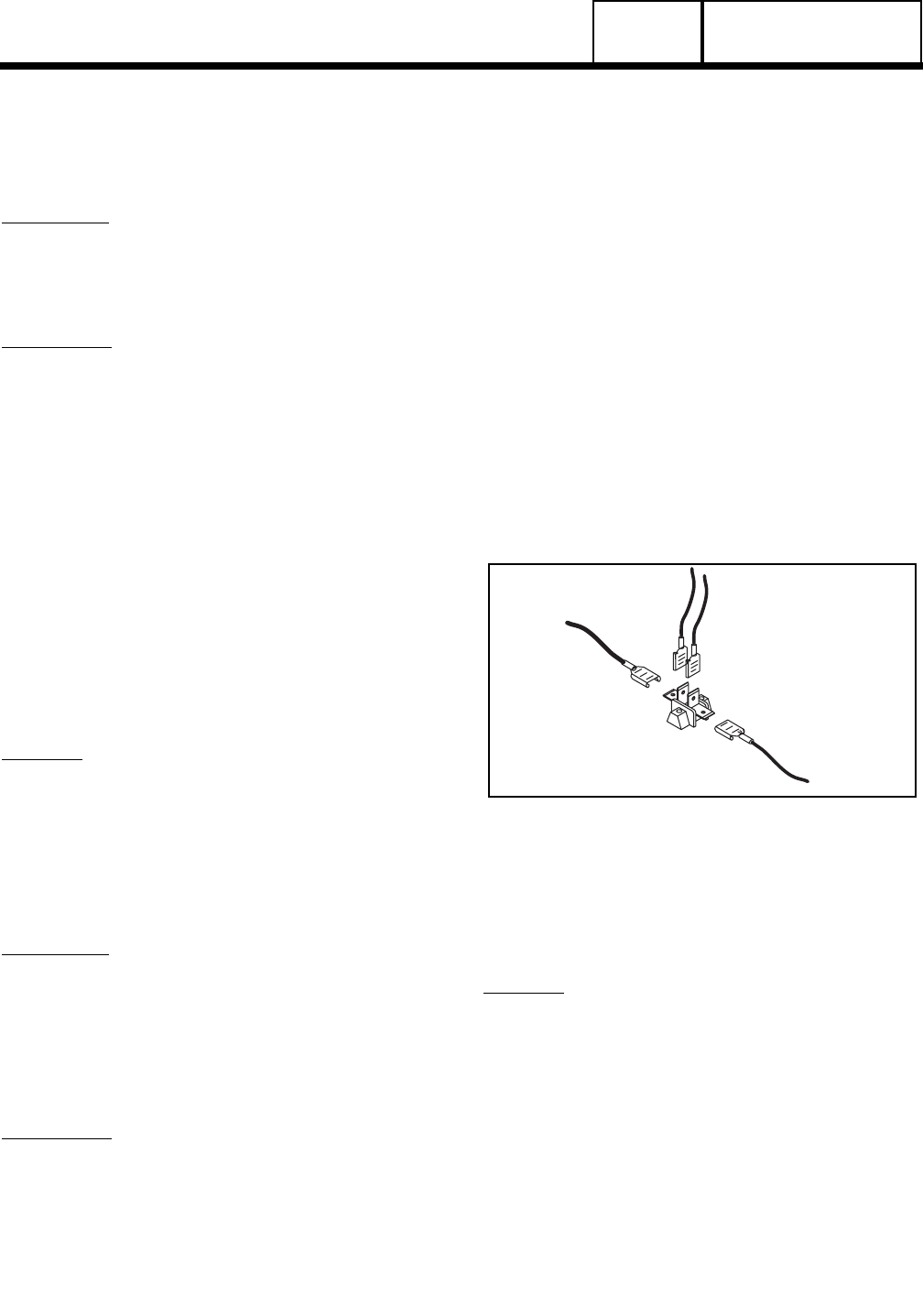

b. Connect the positive (+) test lead to Wire 14 at the 4-tab

terminal block in the control panel, see Figure 17.

Connect the negative (-) test lead to frame ground. While

observing the meter, set the AUTO-OFF-MANUAL

switch to MANUAL. Battery voltage should be measured.

Figure 17. 4-Tab Terminal Block

5. Set the VOM to it’s “R x 1” scale.

6. Disconnect Wire 0 from the Fuel Solenoid (FS). Connect

one test lead to Wire 0 and the other test lead to a clean

frame ground. CONTINUITY should be measured.

RESULTS:

1. If the engine cranks but does not start and battery voltage

was NOT measured in Step 3, replace the circuit board.

2. If the engine cranks and battery voltage was measured

in Step 3, but there was no battery voltage in Step 4(a),

repair or replace Wire 14 between 4-tab terminal block

and the Fuel Solenoid (FS).

3. If the engine cranks and battery voltage was measured

in step 3 and no battery voltage is measured in step 4b,

repair or replace Wire 14 between the J1 connector on

the circuit board and the 4-tab terminal block.

DC CONTROL

Page 4.4-10