Section 1

GENERATOR FUNDAMENTALS

FIELD BOOST

When the engine is cranked during startup, the starter

contactor is energized closed. Battery voltage is then

delivered to the starter motor and the engine cranks.

During cranking, battery voltage flows through a resis-

tor and a field boost diode in the Printed Circuit Board,

then to the Rotor via brushes and slip rings. This is

called “Field Boost” voltage.

Field boost voltage is delivered to the Rotor only while

the engine is cranking. The effect is to “flash the field”

every time the engine is cranked. Field boost voltage

helps ensure that sufficient “pickup” voltage is avail-

able on every startup to turn the Voltage Regulator on

and build AC output voltage.

NOTE: Loss of the Field Boost function may or

may not result in loss of AC power winding output.

If Rotor residual magnetism alone is sufficient to

turn the Regulator on, loss of Field Boost may go

unnoticed. However, if residual magnetism alone

is not enough to turn the Regulator on, loss of the

Field Boost function will result in loss of AC power

winding output to the load. The AC output voltage

will then drop to a value commensurate with the

Rotor’s residual magnetism (about 7-12 VAC).

GENERATOR AC CONNECTION SYSTEM

These air-cooled generator sets are equipped with

dual stator AC power windings. These two stator wind-

ings supply electrical power to customer electrical

loads by means of a dual 2-wire connection system.

Generators may be installed to provide the following

outputs:

1. 120 VAC loads only — one load with a maximum

total wattage requirement equal to the generator’s

rated power output (in watts), and 120 VAC across

the generator output terminals. Figure 1-8, page

7, shows the generator lead wire connections for

120 VAC ONLY.

2. 120/240 VAC loads — one load with a maximum

total wattage requirement equal to the generator’s

rated power output, and 240 VAC across the gen-

erator output terminals; or two separate loads,

each with a maximum total wattage requirement

equal to half of the generator’s rated power out-

put (in watts), and 120 VAC across the generator

output terminals. Figure 1-9 on page 7, shows the

generator lead wire connections for 120/240 VAC

loads.

You can use your generator set to supply electrical

power for operating one of the following electrical

loads:

• RV45G&LP:120and/or240volts,singlephase,

60 Hz electrical loads. These loads can require up

to 4500 watts (4.5 kW) of total power, but cannot

exceed 45.8 AC amperes of current at 120 volts or

exceed 22.9 AC amperes at 240 volts.

• RV55G&LP:120and/or240volts,singlephase,

60 Hz electrical loads. These loads can require up

to 5500 watts (5.5 kW) of total power, but cannot

exceed 54.1 AC amperes of current at 120 volts or

exceed 27 AC amperes at 240 volts.

• RV65G&LP:120and/or240volts,singlephase,

60 Hz electrical loads. These loads can require up

to 6500 watts (6.5 kW) of total power, but cannot

exceed 62.5 AC amperes of current at 120 volts or

exceed 31.2 AC amperes at 240 volts.

*

Caution! Do not overload the generator. Some

installations may require that electrical loads

be alternated to avoid overloading. Applying

excessively high electrical loads may damage

the generator and may shorten its life. Add up

the rated watts of all electrical lighting, appli-

ance, tool and motor loads the generator will

power at one time. This total should not be

greater than the wattage capacity of the gen-

erator. If an electrical device nameplate gives

only volts and amps, multiply volts times

amps to obtain watts (volts x amps = watts).

Some electric motors require more watts of

power (or amps of current) for starting than

for continuous operation.

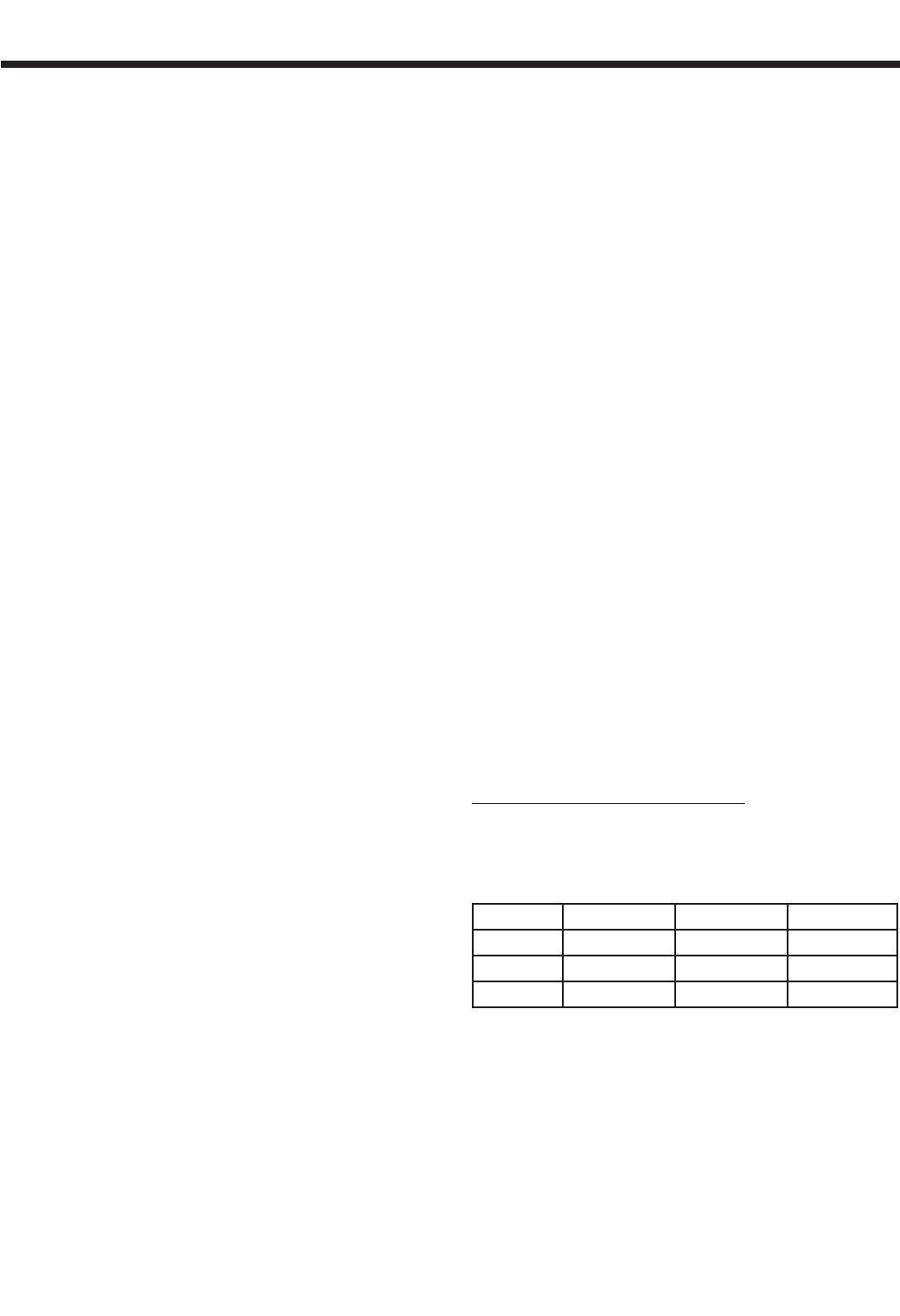

LINE BREAKERS (120 VOLTS ONLY):

Protects generator’s AC output circuit against

overload, i.e., prevents unit from exceeding wattage/

amperage capacity. The circuit breaker ratings are as

follows:

Model Cir. Breaker 1 Cir. Breaker 2 240 Volt

RV 45 20A 20A 20A 2P

RV 55 20A 30A 25A 2P

RV 65 30A 30A 30A 2P

Page 6