Section 7

DIAGNOSTIC TESTS

RESULTS:

1. If Choke Plate is binding in Step 1, repair or

replace binding Choke Plate. If Bi-Metal Heater

Assembly tests good, go to Test 32.

2. If continuity was not measured in Step 3, repair or

replace Wire 14 between the 4-tab Connector and

Connector 3.

3. If the resistance value is incorrect in the Short to

Ground step, or the Bi-Metal Heater Assembly

does not function with voltage present, replace

the Bi-Metal Heater Assembly.

TEST 41 – CHECK LPG FUEL SOLENOID

DISCUSSION:

If the LPG Fuel Solenoid (FS) fails to open, fuel will

not be available to the engine and it will not start.

PROCEDURE:

1.

Place one hand on the top of the LPG Fuel

Solenoid. Activate the Fuel Prime Switch. You

should be able to feel as well as hear the solenoid

energize. If solenoid energizes discontinue testing.

2. Set VOM to measure resistance. Disconnect Wire

0 from the LPG Fuel Solenoid. Connect one meter

test lead to Wire 0. Connect the other test lead to

a clean frame ground. “Continuity” should be mea-

sured. Reconnect Wire 0 to LPG shut off valve.

SHORT TO GROUND:

Set VOM to measure resistance. Disconnect Wire 14A

from the LPG Fuel Solenoid. Connect one meter test

lead to LPG Fuel Solenoid. terminal that Wire 14A

was just removed from. Connect the other meter test

lead to a clean frame ground. LPG Fuel Solenoid.

Coil resistance of approximately 30-32 ohms Should

be measured. Current draw of the LPG Fuel Solenoid

at nominal voltage Is approximately 380 milliamps or

0.380 amps.

RESULTS:

1. If the solenoid energized in Step 1, proceed to

Test 29.

2. If “Continuity” was not measured in Step 2 repair

or replace Wire 0 between the LPG Fuel Solenoid

(FS) and the Ground Terminal (GRD1) in the con-

trol panel.

3. If “Continuity” was measured in Step 2, repair or

replace the Fuel Solenoid (FS).

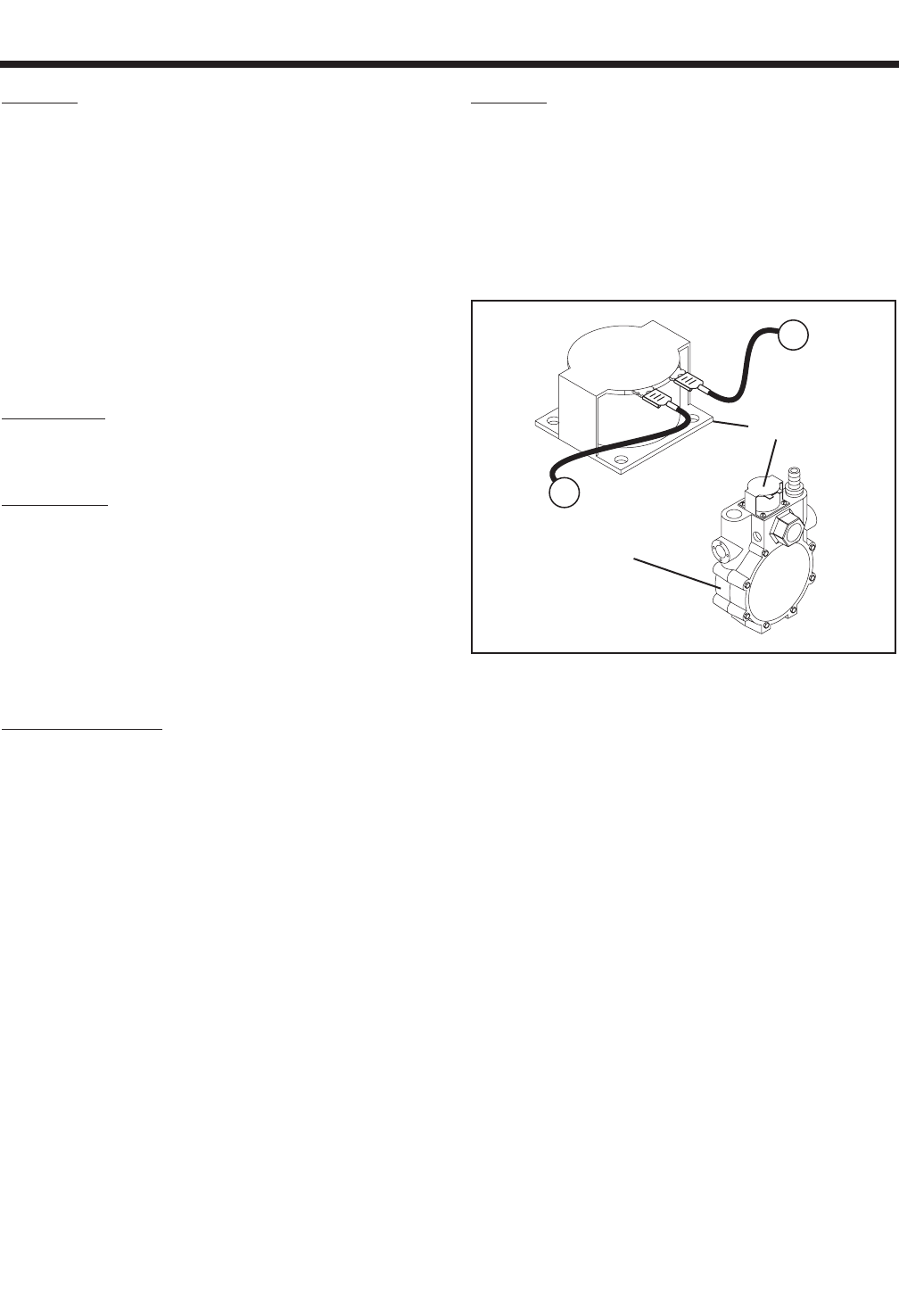

FUEL SOLENOID

FUEL REGULATOR

0

241

Figure 7-49. – Fuel Solenoid

Page 63