Section 7

DIAGNOSTIC TESTS

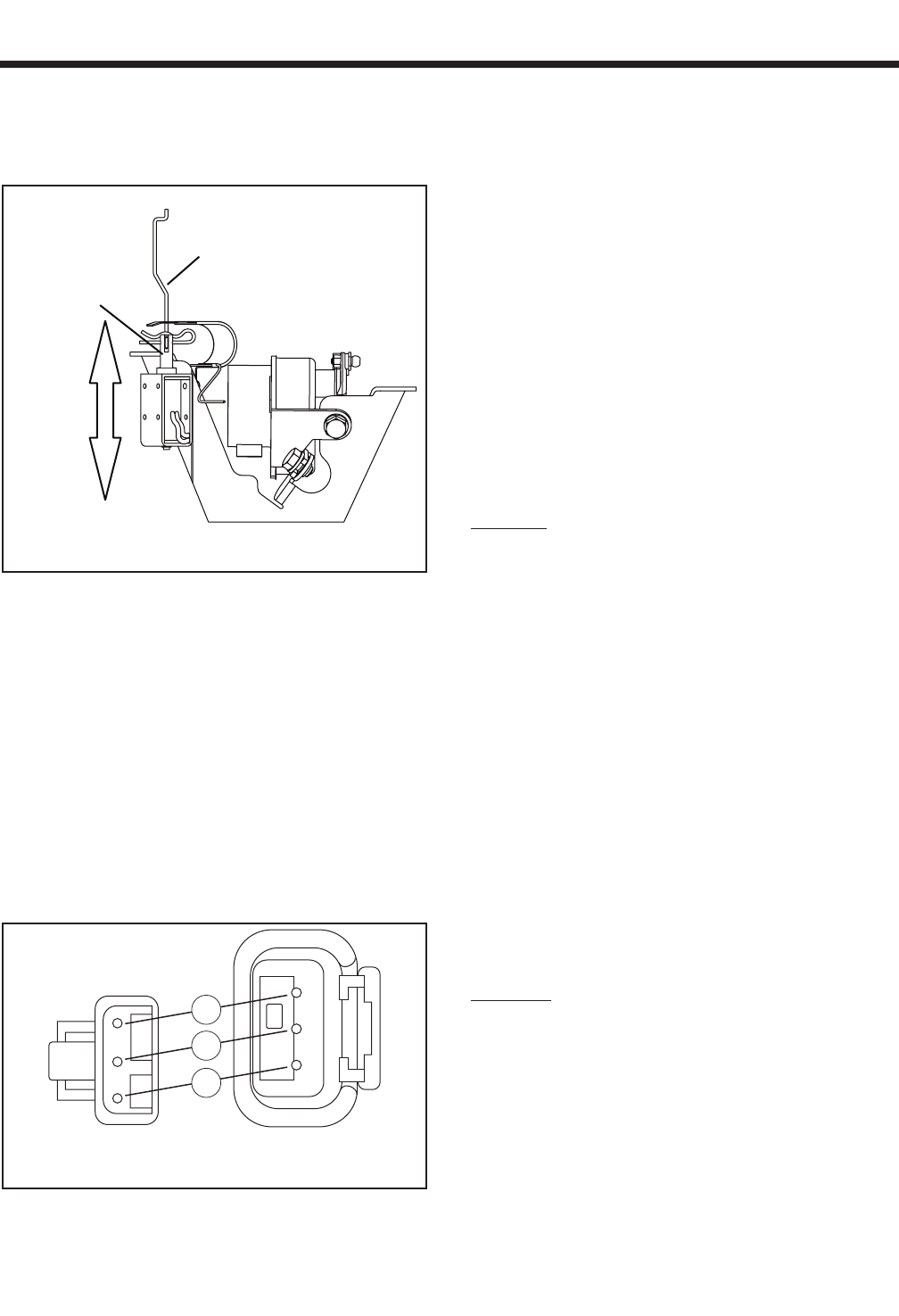

in its coil, tighten the two screws. Verify that the

choke solenoid plunger and linkage move freely

without any drag or resistance that may restrict

movement.

CHOKE CONTROL ROD

CHOKE SOLENOID

MOVES VERTICALLY

PLUNGER

Figure 7-42. – Choke Solenoid Adjustment

4. Disconnect Connector 3: Set the VOM to measure

DC voltage. Connect the positive (+) test lead to

Wire 90 (Pin 2) of Connector 3 going to the control

panel. Connect the negative (-) test lead to frame

ground. Activate the Start-Stop Switch to “START.”

During cranking, battery voltage should be mea-

sured cyclically every two seconds.

5. If battery voltage was not measured in Step 4,

check at J1 Connector: Connect positive (+) test

lead to Pin Location J1-2 at the Printed Circuit

Board. Connect the negative (-) test lead to frame

ground. Activate the Start-Stop Switch to “START.”

During cranking, battery voltage should be mea-

sured cyclically every two seconds.

1

3

90

2

2

3

1

14

14

TO CONTROL

PANEL

TO CHOKE

SOLENOID

Figure 7-43. – Connector 3

6. Set the VOM to measure resistance.

Disconnect

Connector 3 from the Choke Solenoid.

Connect

one test lead to Wire 0 (Pin 1) of Connector 3,

going to the control panel. Connect the other test

lead to frame ground.

“

Continuity” should be mea-

sured.

7. Set the VOM to measure resistance. Disconnect

Connector 3. Connect one meter test lead to

Wire 90 (Connector 3, Pin 2) going to the Choke

Solenoid. Connect the other meter test lead to

Wire 0 (Connector 3, Pin 1). Approximately 3.7

ohms should be measured. (Current draw of

Choke Solenoid at nominal voltage is 3.4 amps).

Short to Ground:

8. Set the VOM to measure resistance. Disconnect

Connector 3. Connect one meter test lead to Wire

90 (Connector 3, Pin 2). Connect the other meter

test lead to the metal Choke Solenoid housing.

“Infinity” should be measured. If “Continuity” is

measured, a short to ground exists.

RESULTS:

1. If Choke operation is good, go to Test 32 for

Problem 7, “Engine Cranks but Won’t Start”

(Section 6). Go to Test 41 for Problem 8, “Engine

Starts Hard and Runs Rough”.

2. If battery voltage was measured in Step 5 but

not measured in Step 4, repair or replace Wire

90 between Printed Circuit Board (PCB) and

Connector 3.

3. If battery voltage is not measured in Step 5 during

engine cranking, replace PCB.

4. If

“

Continuity” is not measured in Step 6, repair or

replace Wire 0 between the ground terminal and

Connector 3.

5. If Choke Solenoid coil resistance is not mea-

sured or is incorrect in Step 7, replace the Choke

Solenoid.

TEST 35 – CHECK ENGINE / CYLINDER LEAK

DOWN TEST / COMPRESSION TEST

GENERAL:

Most engine problems may be classified as one or a

combination of the following:

❏Will not start.

❏ Starts hard.

❏ Lack of power.

❏ Runs rough.

❏ Vibration.

❏ Overheating.

❏ High oil consumption.

Page 59