Page 58

TEST 33 – CHECK CARBURETION

DISCUSSION:

If the engine cranks but will not start, one possible

cause of the problem might be the carburetion system.

PROCEDURE:

Before making a carburetion check, be sure the fuel sup-

ply tank has an ample supply of fresh, clean gasoline.

Check that all shutoff valves are open and fuel flows

freely through the fuel line.

Make sure the automatic choke operates properly.

If the engine will not start, remove and inspect the spark

plug. If the spark plug is wet, look for the following:

❏Overchoking.

❏Excessively rich fuel mixture.

❏Water in fuel.

❏Intake valve stuck open.

❏ Needle/float stuck open.

If the spark plug is dry look for the following:

❏ Leaking carburetor mounting gaskets.

❏ Intake valve stuck closed.

❏ Inoperative fuel pump.

❏ Plugged fuel filter(s).

❏ Varnished carburetor

If the engine starts hard or will not start, look for the

following:

❏Physical damage to the AC generator. Check the

Rotor for contact with the Stator.

❏Starting under load. Make sure all loads are discon-

nected or turned off before attempting to crank and

start the engine.

❏Check that the automatic choke is working properly.

RESULTS:

If problem has not been solved, go to Test 34. If car-

buretor is varnished, clean or replace.

1. Remove fuel line at carburetor and ensure that

there is an adequate amount of fuel entering the

carburetor.

2. Remove the float bowl and check to see if there is

any foreign matter in bottom of carburetor bowl.

3. The float is plastic and can be removed for access

to the needle so it can be cleaned.

4. With all of this removed carburetor cleaner can

be used to clean the rest of the carburetor before

reassembly.

5. After cleaning carburetor with an approved carbu-

retor cleaner, blow dry with compressed air and

reassemble.

Shelf life on gasoline is 30 days. Proper procedures

need to be taken for carburetors so that the fuel doesn’t

varnish over time. A fuel stabilizer must be used at all

times in order to ensure that the fuel is fresh at all times.

TEST 34 – CHECK CHOKE SOLENOID

DISCUSSION:

The automatic choke is active only during cranking.

When the Start-Stop Switch is held at “START”, a

crank relay on the Printed Circuit Board is energized

closed to (a) crank the engine and (b) deliver a cyclic

voltage to the Choke Solenoid via Wire 14. The Choke

Solenoid will be pulled in for about two seconds, then

deactivate for about two seconds. This cyclic choking

action will continue as long as the engine is being

cranked.

PROCEDURE:

1. Operational Check: Crank the engine. While

cranking, the choke solenoid should pull in about

every 2 seconds (2 seconds ON, 2 seconds OFF).

If the choke solenoid does not pull in, try adjusting

the choke as follows.

2. Pre-Choke Adjustment: With the CHOKE

SOLENOID not actuated, the carburetor CHOKE

PLATE should be approximately 1/8 Inch from its

full open position. Verify choke is completely open

once engine is warmed up. If not, power will be

down and emissions will be up. Adjust position

of BI-METAL HEATER ASSEMBLY by loosening

screws until unit starts when cold and the choke

closes when engine is up to temperature. Tighten

the screws to complete the adjustment.

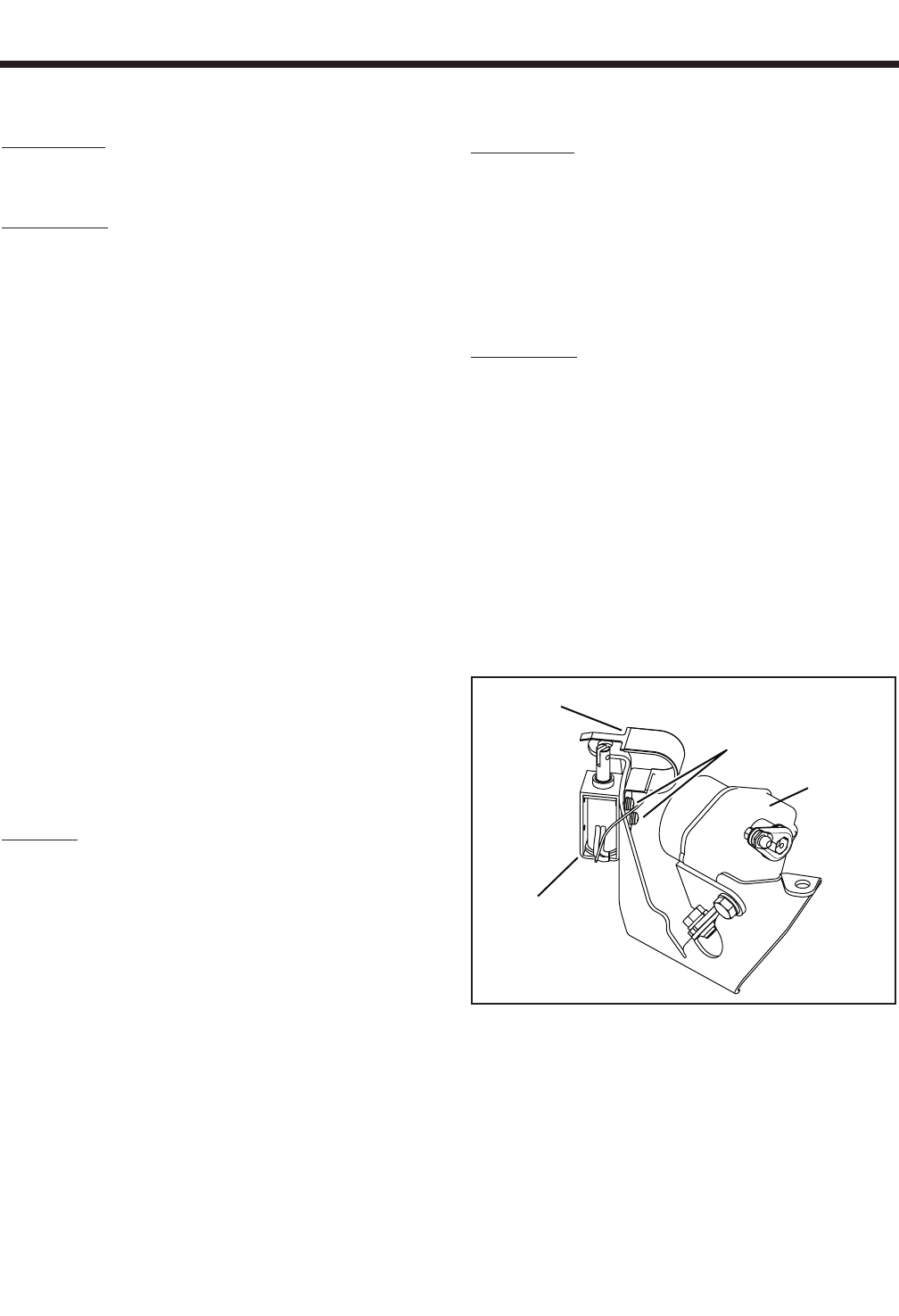

CHOKE

SOLENOID

BI-METAL

HEATER

SCREWS

STEPPER

MOTOR

Figure 7-41. – Automatic Choke Assembly

3. Choke Solenoid Adjustment: Loosen the screws

that retain the CHOKE SOLENOID to its brack-

et. Slide the CHOKE SOLENOID in the slotted

holes of the bracket to adjust axial movement of

the SOLENOID PLUNGER. Adjust SOLENOID

PLUNGER movement until, with the carburetor

CHOKE PLATE 0.5mm from closed, the CHOKE

SOLENOID is bottomed in its coil (plunger at

full actuated position). With the CHOKE PLATE

0.5mm from closed and the plunger bottomed

Section 7

DIAGNOSTIC TESTS