3. If

“

Continuity” is not measured in Step 5, repair

or replace Wire 0 between the Fuel Solenoid and

ground terminal.

4. If

“

Continuity” is not measured in Step 6, repair or

replace Carburetor ground wire.

5. If the Fuel Solenoid operates, proceed to Test 29.

TEST 29 – CHECK IGNITION SPARK

DISCUSSION:

A problem in the engine ignition system can cause

any of the following:

• Enginewillnotstart.

• Enginestartshard,runsrough.

A commercially available spark tester may be used to

test the engine ignition system. One can also be pur-

chased from Generac Power Systems (P/N 0C5969).

PROCEDURE:

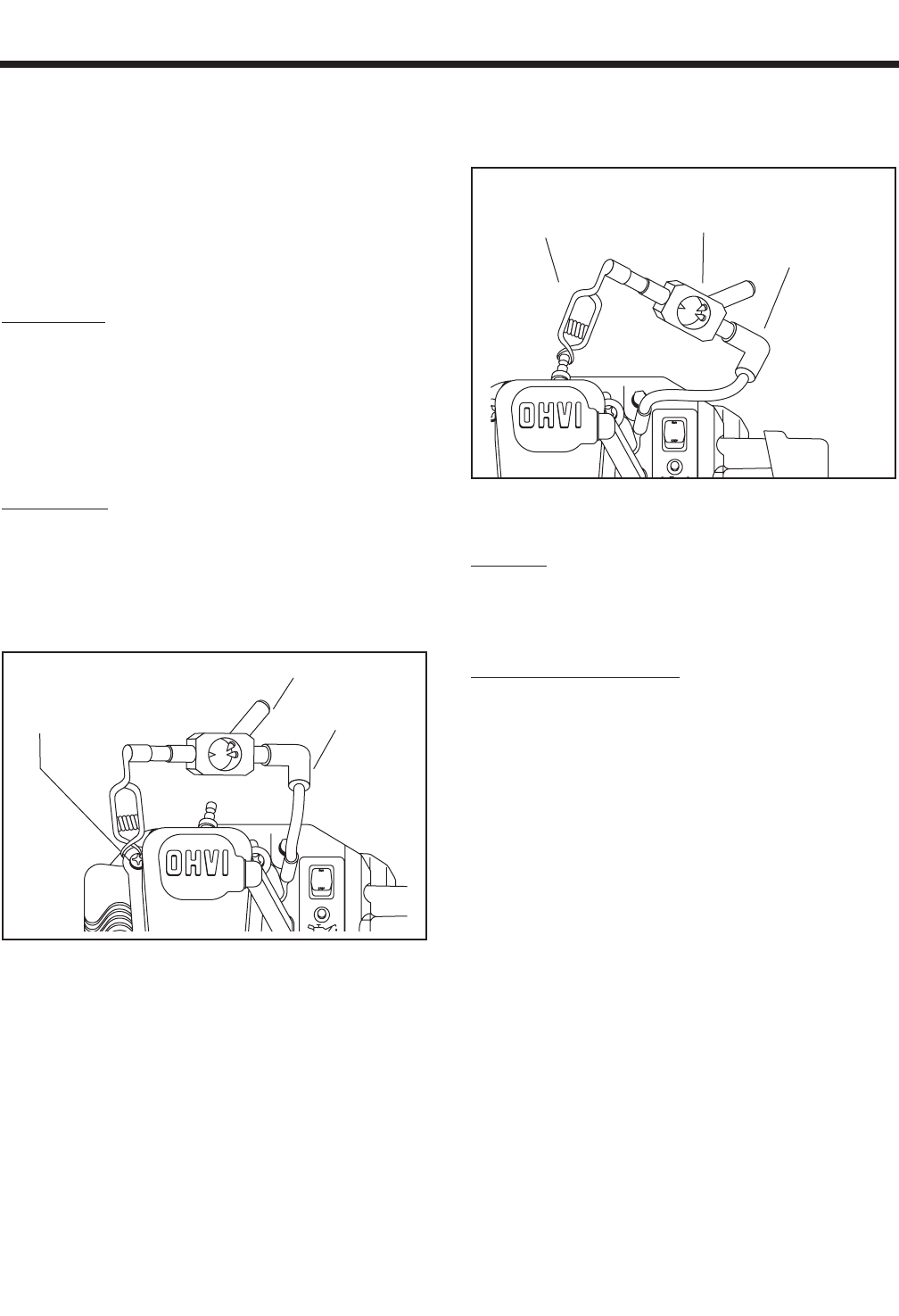

1. Disconnect a high tension lead from a spark plug.

2. Attach the high tension lead to the spark tester

terminal.

3. Ground the spark tester clamp by attaching to the

cylinder head (see Figure 7-32).

SPARK TESTER CLAMP

GROUNDED TO

CYLINDER HEAD

SPARK TESTER

SPARK PLUG

BOOT

Figure 7-32. – Testing Ignition System

4. Crank the engine rapidly. Engine must be crank-

ing at 350 rpm or more. If spark jumps the tester

gap, you may assume the ignition system is work-

ing properly. Repeat on remaining cylinder spark

plug.

5. To determine if an engine miss is ignition related,

connect the spark tester in series with the high

tension lead and the spark plug. Then, start the

engine. If spark jumps the tester gap at regu-

lar Intervals, but the engine miss continues, the

problem may be in the spark plug or fuel system.

Repeat on remaining cylinder spark plug. Proceed

to Test 30.

6. If spark jumps the tester gap intermittently, the

problem may be in the Ignition Magneto. Proceed

to Test 31.

SPARK TESTER CLAMP

CONNECTED TO

SPARK PLUG

SPARK TESTER

SPARK PLUG

BOOT

Figure 7-33. – Checking Engine Miss

RESULTS:

1. If no spark or if engine miss is apparent, go to

Test 31.

2. If ignition spark is good, go to Test 30.

CYLINDER BALANCE TEST:

If the engine is hard starting, runs rough, misses or

lacks power, perform a cylinder balance test to deter-

mine whether both cylinders are operating to their full

potential.

Tools Required:Two Ignition Testers (Generac P/N

0C5969)

Attach an ignition tester between the spark plug lead

and each spark plug (Figure 7-33).

Start and run engine running at top no load speed

and note spark at ignition testers. If the spark is equal

at both ignition testers, the problem is not ignition

related. A spark miss will be readily apparent. Now

note RPM of engine. Ground out one cylinder by con-

tacting ignition tester and a good ground on engine as

shown in Figure 7-34. Note RPM loss. Reattach plug

wire then repeat procedure with the other cylinder.

Note the RPM loss. If the difference between the two

cylinders does not exceed 75 RPM, the amount of

work the two cylinders are doing should be consid-

ered equal.

If the RPM loss is greater than 75 RPM this indicates

that the grounded cylinder with the least RPM loss is

the weakest of the two cylinders. Look to that cylinder

for a problem.

Example:

Engine RPM - Both Cylinders = 2570 RPM

Engine RPM - No. 1 Cylinder Grounded = 2500 RPM

Engine RPM - No. 2 Cylinder Grounded = 2300 RPM

Conclusion: No. 1 cylinder is weakest of the two cylinders.

Page 54

Section 7

DIAGNOSTIC TESTS