Section 7

DIAGNOSTIC TESTS

TEST 14 – TRY CRANKING THE ENGINE

DISCUSSION:

If the Start-Stop Switch on the generator panel is

actuated, but the Fuel Pump does not run (priming

function doesn’t work), perhaps battery voltage is not

available.

PROCEDURE:

Hold the Start-Stop Switch at “START”. The engine

should crank and start.

RESULTS:

1. If the engine cranks normally, but the priming

function still doesn’t work, go to Test 20.

2. If engine will not crank, go to Test 16. Refer to

Problem 6 of Section 6.

3. If engine cranks but won’t start, go to Problem 7

of Section 6.

4. If engine starts hard and runs rough, go to

Problem 8 of Section 6.

TEST 15 – CHECK FUEL PUMP

DISCUSSION:

An inoperative Fuel Pump will (a) prevent the priming

function from working and (b) prevent the engine from

starting.

PROCEDURE:

1. Remove Fuel Filter and verify that filter is not

clogged. Replace filter if necessary.

2. Verify that fuel is available to Fuel Filter inlet. Use

an alternative fuel supply if questionable.

3. Remove air filter access panel and air filter.

Remove fuel hose from pump. Place a suit-

able container to catch fuel from fuel pump line.

Activate fuel primer switch. Pump should operate

and fuel should flow. If pump does not operate,

proceed to Step 4.

4. This step will test the ground wire. Disconnect

Connector 2 at the Fuel Pump. Set the VOM to

measure resistance. Connect one test lead to

the Black wire, (Pin 2 of Connector 2) that goes

to the Control Panel (see Figure 7-14). Connect

the other test lead to a clean frame ground .

“Continuity” should be measured.

5. To test for an open fuel pump coil, connect one

test lead to the Red Wire (Pin 1 of Connector 2)

going to the fuel pump. Connect the other test lead

to the Black Wire (Pin 2 of Connector 2) going to

the Fuel Pump (see Figure 7-14). The VOM should

indicate Fuel Pump coil resistance of about 29.5

kW. (Current draw of the pump at nominal voltage

is approximately 1.4 amperes MAXIMUM).

Short to Ground:

6. To test for a shorted fuel pump coil, connect one

test lead to the Red Wire

(Pin 2 of Connector 2,

see Figure 7-14)

. Connect the other test lead to

the fuel pump housing. “Infinity” should be mea-

sured.

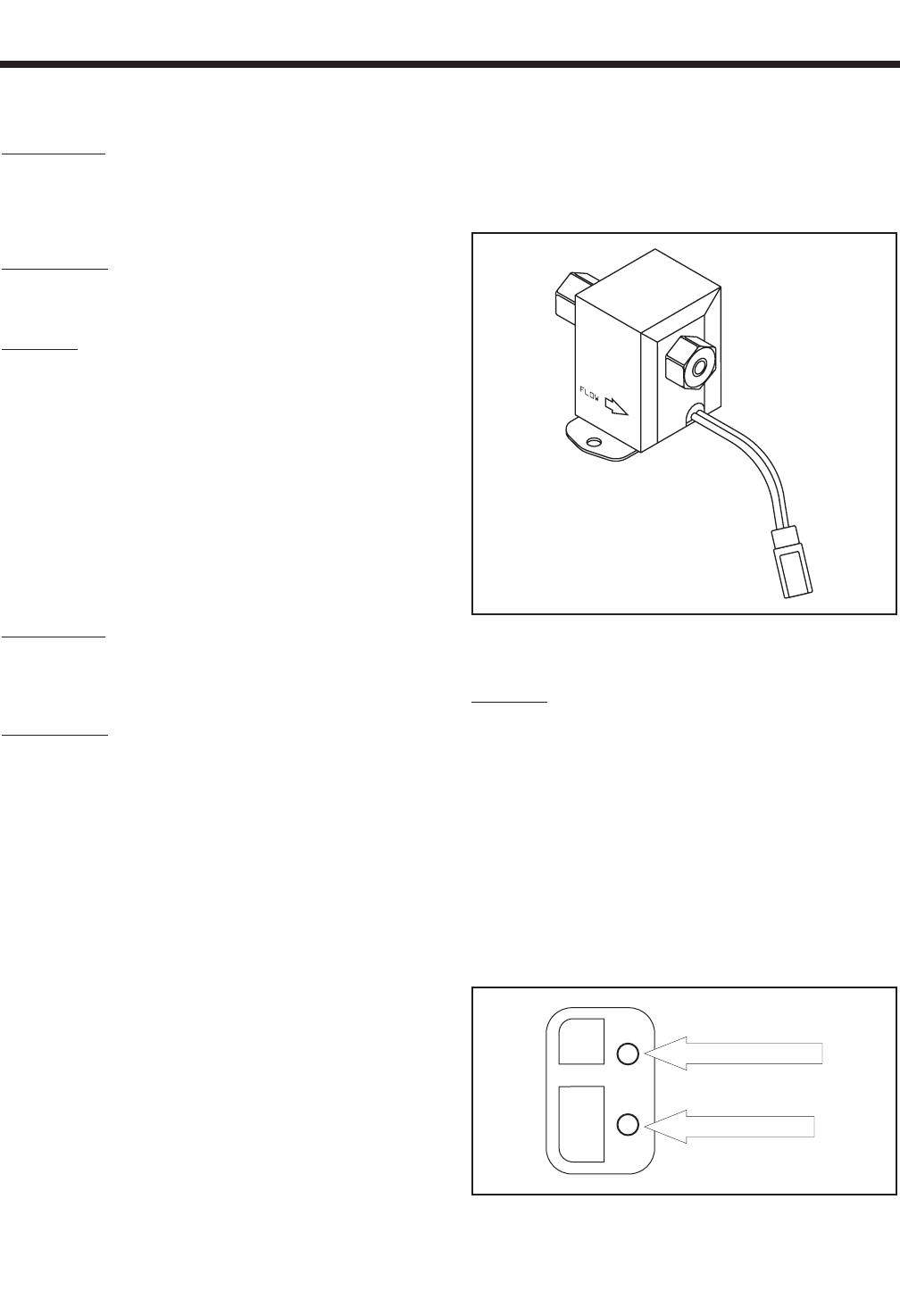

FLOW

Figure 7-13. – Electric Fuel Pump

RESULTS:

1. If “Continuity” was not measured in Step 4, repair

or replace Wire 0 between Connector 2 and the

ground terminal.

2. If “Continuity” is measured in Step 4, but pump

does not operate in Step 3, replace the Fuel

Pump.

3. If the pump fails Step 5 or Step 6, replace the

Fuel Pump.

Note: If desired, a pressure gauge can be attached

to the pumps outlet side. Pump outlet pressure

should be 2.0 to 3.5 psi.

4. If the pump operates normally, go to Test 28.

PIN 1 - RED WIRE

PIN 2 - BLACK WIRE

Figure 7-14. – Harness to Fuel Pump

Page 44