Section 7

DIAGNOSTIC TESTS

be indicated by excessive current draw or no

RPM.

3. A defective Starter Motor switch.

4. Broken, damaged or weak magnets.

5. Starter drive dirty or binding.

DISCUSSION:

Test 21 verified that Printed Circuit Board action is

delivering DC voltage to the Starter Contactor Relay

(SCR). Test 22 verified the operation of the SCR. Test

23 verified the operation of the Starter Contactor (SC).

Another possible cause of an “engine won’t crank”

problem is a failure of the Starter Motor.

PROCEDURE:

The battery should have been checked prior to this

test and should be fully charged.

Set a VOM to measure DC voltage (12 VDC).

Connect the meter positive (+) test lead to the Starter

Contactor stud which has the small jumper wire con-

nected to the Starter. Connect the common (-) test

lead to the Starter Motor frame.

Set the Start-Stop Switch to its “Start” position and

observe the meter. Meter should Indicate battery volt-

age, Starter Motor should operate and engine should

crank.

RESULTS:

1. If battery voltage is indicated on the meter but

Starter Motor did not operate, remove and bench

test the Starter Motor (see following test).

2. If battery voltage was indicated and the Starter

Motor tried to engage (pinion engaged), but

engine did not crank, check for mechanical bind-

ing of the engine or rotor.

If engine turns over slightly, go to Test 32 “Check and

Adjust Valves.”

NOTE: If a starting problem is encountered, the

engine itself should be thoroughly checked to

eliminate it as the cause of starting difficulty. It is

a good practice to check the engine for freedom

of rotation by removing the spark plugs and turn-

ing the crankshaft over slowly by hand, to be sure

it rotates freely.

*

WARNING! DO NOT ROTATE ENGINE WITH

ELECTRIC STARTER WITH SPARK PLUGS

REMOVED. ARCING AT THE SPARK PLUG

ENDS MAY IGNITE THE GASOLINE VAPOR

EXITING THE SPARK PLUG HOLE.

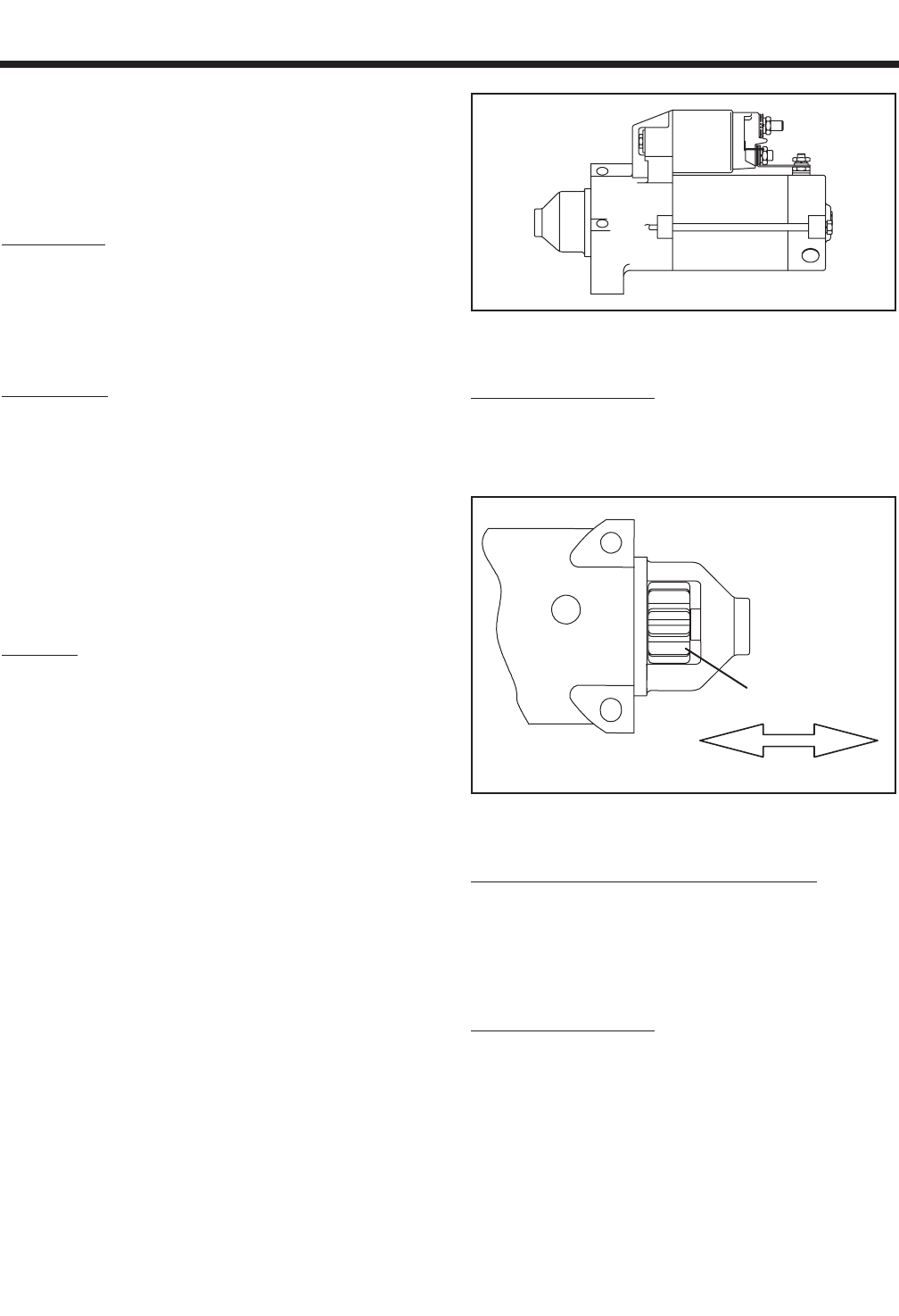

Figure 7-21. – Starter Motor (SM)

CHECKING THE PINION:

When the Starter Motor is activated, the pinion gear

should move and engage the flywheel ring gear. If the

pinion does not move normally, inspect the pinion for

binding or sticking.

PINION

Figure 7-22. – Check Pinion Gear Operation

TOOLS FOR STARTER PERFORMANCE TEST:

The following equipment may be used to complete a

performance test of the Starter Motor:

❏ A clamp-on ammeter.

❏ A tachometer capable of reading up to 10,000 rpm.

❏ A fully charged 12-volt battery.

MEASURING CURRENT:

To read the current flow, in AMPERES, a clamp-on

ammeter may be used. This type of meter indicates

current flow through a conductor by measuring the

strength of the magnetic field around that conductor.

Page 49