T190 Compact Track Loader

Operation & Maintenance Manual 44

TRACK CARRIAGE SYSTEM

Introduction

There are many advantages of a Bobcat Compact Track

Loader. They provide very high flotation, low ground

pressure, turf friendly rubber tracks and excellent

traction.

Compact Track Loader Operating And Maintenance

Tips

Track Tension: Correct track tension is important. If the

tracks are too loose, they can easily derail. If they are too

tight, they will wear faster and cause increased stress on

the complete track carriage system. (See TRACK

TENSION on Page 96.)

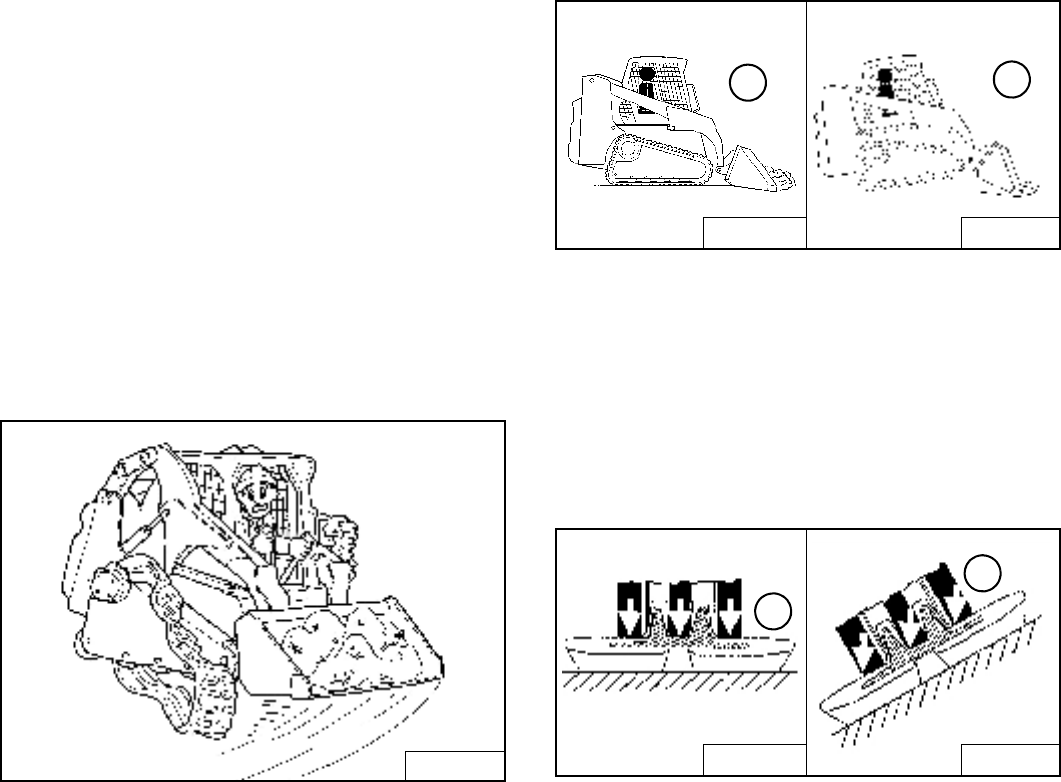

Figure 90

Turning: Use a gradual turn (one lever farther forward

than the other) instead of a fast turn (one lever forward

and one lever backward) on asphalt or concrete surfaces

to prevent reduced track life or derailing of tracks

[Figure 90].

Always carry the load low.

Figure 91

Digging And Leveling: Keep the full length of the tracks

in contact with the ground (1) [Figure 91] for best

traction. Raising the front end of the tracks off the

ground (2) [Figure 91] will reduce traction and cause

increased track wear.

Operating On Slopes: Go directly up or down a slope,

not across the slope to prevent tracks from derailing.

Figure 92

The track carriage components will wear faster when

operated on a slope. When the machine is operated on a

level surface, the weight of the machine is distributed

throughout the entire surface of the rollers to the

tracks (1) [Figure 92]. When operated on a slope, the

weight is directed to the edge of the rollers and against

the lugs of the track (2) [Figure 92] which causes

increased wear.

B-16978A

WRONG

TS-2026

TS-2025

CORRECT

1

WRONG

2

B-17824C

B-17824B

1

2