T190 Compact Track Loader

Operation & Maintenance Manual 100

DRIVE BELT

Belt Adjustment

Stop the engine.

Open the rear door and disconnect the negative (-) cable

from the battery.

Remove three belt shield fasteners and remove the belt

shield.

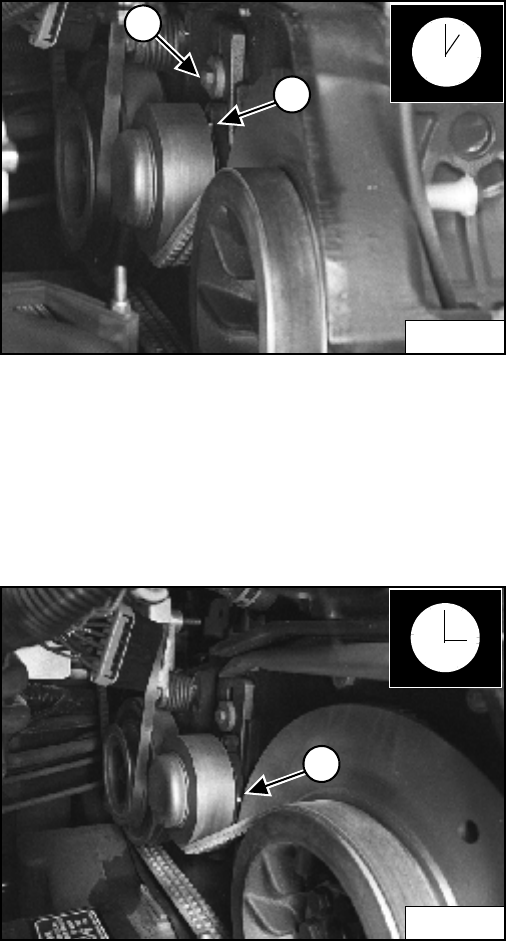

Figure 181

Loosen the bolt (1) [Figure 181] on the spring loaded

drive idler.

NOTE: The pointer will be at the 1 o'clock position (2)

[Figure 181] when the belt tensioner is not

under spring tension.

Figure 182

Push the idler pulley against the belt, using a pry bar

[Figure 182]. The pointer will be at the 3 o'clock

position (1) [Figure 182] when the idler pulley is against

the stop (maximum movement).

Raise the idler assembly slightly so that the pulley is

operating on spring tension and not against the stop.

NOTE: Do not set the idler against the travel stop in

the 3 o'clock position.

Tighten the mounting bolt (1) [Figure 182] to 34-38 Nm

torque.

Run the engine for a few minutes. Stop the engine and

recheck the pointer position.

Readjust if necessary.

After the idler has been in service, readjust when the

pointer reaches the 1 o'clock position.

Install the belt shield and fasteners.

Connect the negative (-) battery cable.

Close the rear door.

Belt Replacement

Follow the steps above to loosen the drive belt tensioner.

Remove the bolt (1) [Figure 182] from the tensioner and

remove the tensioner assembly.

Remove the fan drive belt.

Remove the drive belt from the pump pulley and flywheel

and remove the belt from the loader.

Install the new drive belt. Install the belt tensioner

assembly.

Install the fan drive belt.

Adjust the drive belt, reinstall previously removed

components and continue procedure from Adjusting The

Drive Belt above.

Run the machine for 5 hours and then check belt

adjustment again.

Readjust as necessary.

N-18436

2

1

N-18454

1