T190 Compact Track Loader

97 Operation & Maintenance Manual

TRACK TENSION (CONT’D)

Adjusting (Cont’d)

Decrease Track Tension:

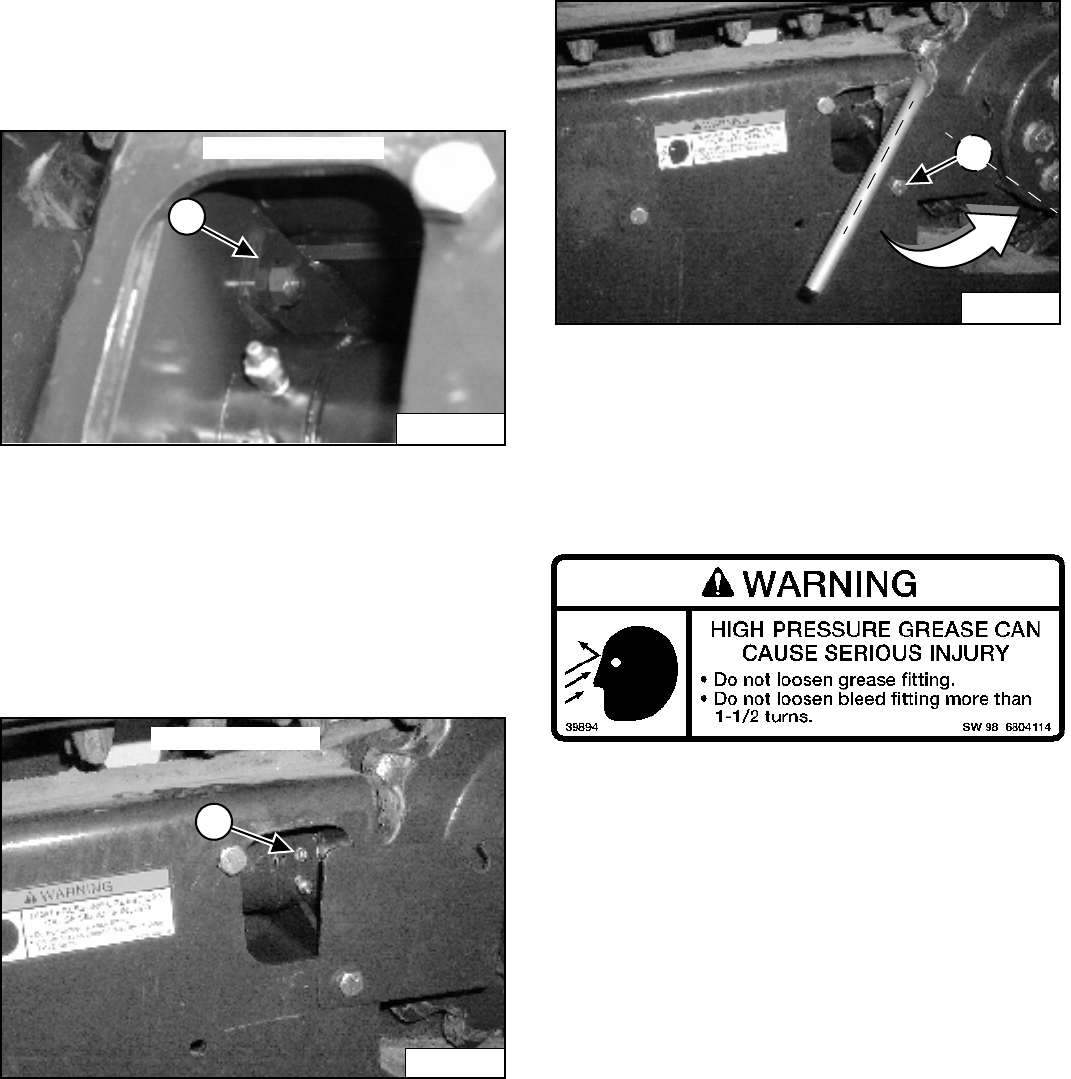

Figure 175

NOTE: There are stop blocks (1) [Figure 175] that

keep the cylinders from turning. If the

cylinders turn, the fittings will not be

accessible. Check the stop block bolts to be

sure they are tight.

Pressure must be released from the spring and

adjustment cylinder to decrease track tension.

Figure 176

Figure 177

Install the bleed tool (MEL-1560) on the bleed fitting (1)

[Figure 176] (upper fitting on left side, lower fitting on

right side).

Adjust and tighten the collar to fit behind the edge of the

access hole and the cover [Figure 177].

Tighten the cover bolt (1) [Figure 177] to secure the tool.

Turn the tool 1/4 turn counterclockwise and let the grease

flow into a container. Turn the tool one additional turn to

continue to release pressure.

Repeat the procedure for the other track.

Dispose of the grease in an environmentally safe manner.

NOTE: Track replacement must be performed by a

qualified Bobcat Technician. See your Bobcat

dealer.

P-26945

1

Right Side Shown

P-24626

Left Side Shown

1

P-24625

1