8

OIL BURNER

P*LBX furnaces are equipped with

Beckett AF Series oil burners with the

Beckett CleanCut pump and R7184B oil

primary control. P*DHX furnaces are

equipped with Beckett AF Series oil

burners with the R8184N oil primary con-

trol. The oil burner must align properly

with the cerafelt fiber chamber (firepot).

The cerafelt fiber chamber is initially

quite soft, but hardens and becomes

quite brittle after the first firing. The fire-

pot is held in place by a retaining

bracket; however, it is possible for the

firepot to shift if subjected to rough han-

dling during transit.

BEFORE OPERATING THE FUR-

NACE CHECK BURNER ALIGNMENT

WITH COMBUSTION CHAMBER.

THE END CONE OF THE AIR TUBE

MUST BE CENTRED TO THE AC-

COMODATING RING PROVIDED IN

THE DESIGN OF THE COMBUSTION

CHAMBER. ADJUST ALIGNMENT AS

NECESSARY BEFORE THE FIRST

FIRING.

OIL BURNER NOZZLES

All furnace models are certified for multi-

ple firing rates. Choose the firing rate

that most closely matches the calculated

heat loss of the building. Models, firing

rates and nozzles are listed in Appendix

A: AF Burner Set-Up.

BURNER ELECTRODES

Correct positioning of the electrode tips

with respect to each other, to the fuel oil

nozzle, and to the rest of the burners is

essential for smooth light ups and proper

operation. The electrode tips should be

adjusted to a gap of 5/32”, 1/16” ahead

of the nozzle, 5/16” above the centerline

of the nozzle. The “Z” dimension (front

edge of the burner head to the front face

of the nozzle is 1-1/8 inches.

Electrode positioning should be checked

before the first firing of the furnace.

The electrode porcelains should be free

of cracks, the electrode tips should be

tapered and free of burrs, and the con-

tact rods must be clean and be in firm

contact with the ignition transformer con-

tact springs. The electrodes must not

come into contact with the burner head.

OIL BURNER SET-UP

The burner air supply is adjusted to

maintain the fuel to air ratio to obtain

ideal combustion conditions. A lack of air

causes "soft" and "sooty" flames, result-

ing in soot build-up throughout the heat

exchanger passages. Excess combus-

tion air causes a bright roaring fire and

high stack temperatures resulting in poor

fuel efficiency.

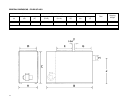

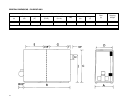

PREPARATIONS:

Drill a ¼” test port in the venting, ideally

at least 2 flue pipe diameters away from

the furnace breeching, if venting horizon-

tally from the furnace, (typically P*LBX)

or from the flue pipe elbow if venting

vertically (typically P*DHX) before reach-

ing the furnace. (see Figures 4 and 5).

The test port will allow flue gas samples

to be taken and stack temperatures to be

measured.

Before starting the burner, check the

burner alignment with the combustion

chamber (fire pot), check that the correct

nozzle is tightened into place, and that

the burner electrodes are properly posi-

tioned.

The Beckett burner bulk air band should

be closed, and the air shutter initial set-

ting should be approximately 7.00.

Note A: Locate hole at least 6 inches on

the furnace side of the draft control.

Note B: Ideally, hole should be at least

12 inches from breeching or elbow.

PROCEDURE:

Start the burner and allow it to run at

least ten minutes. Set the air shutter to

give a good flame visually. The combus-

tion air supply to the burner is controlled

by adjusting the air shutter on the left

side of the burner, and, if necessary, the

bulk air band. To adjust, loosen the bolt

on the movable shutter. Move the shutter

gradually until a good flame (visually)

has been achieved. Re-snug the bolt.

Check the initial draft setting as the fur-

nace warms up. The draft may be meas-

ured at the test port. The final breech

draft should be - 0.02 inches w.c. to

provide adequate over-fire draft.

Fig. 4: Horizontal Smoke Test Port Location Fig. 5: Vertical Smoke Test Port Location