ENGINE

Maintenance, repair, or replacement of

the emission controldevices and sys-

tems, which are being done at the

customers expense, may be performed

by any non-read engine repair establish-

ment or individual.Warranty repairs must

be performed by an authorized engine

manufacturer'sservice outlet.

TO ADJUST THROTTLE CONTROL

CABLE

The throttlecentrol has been presetat the

factory and adjustment should not be

necessary. Check adjustmentas de-

scdbed below before loosening cable. If

adjustment is necessary,proceed as

follows:

1. With engine notrunning, move throttle

control lever to fastposition.

2. Check that speed controllever is

against stop screw. If itis not, loosen

casing clamp screw and pull throttle

cable until lever isagainst screw.

Tighten clamp screw securely.

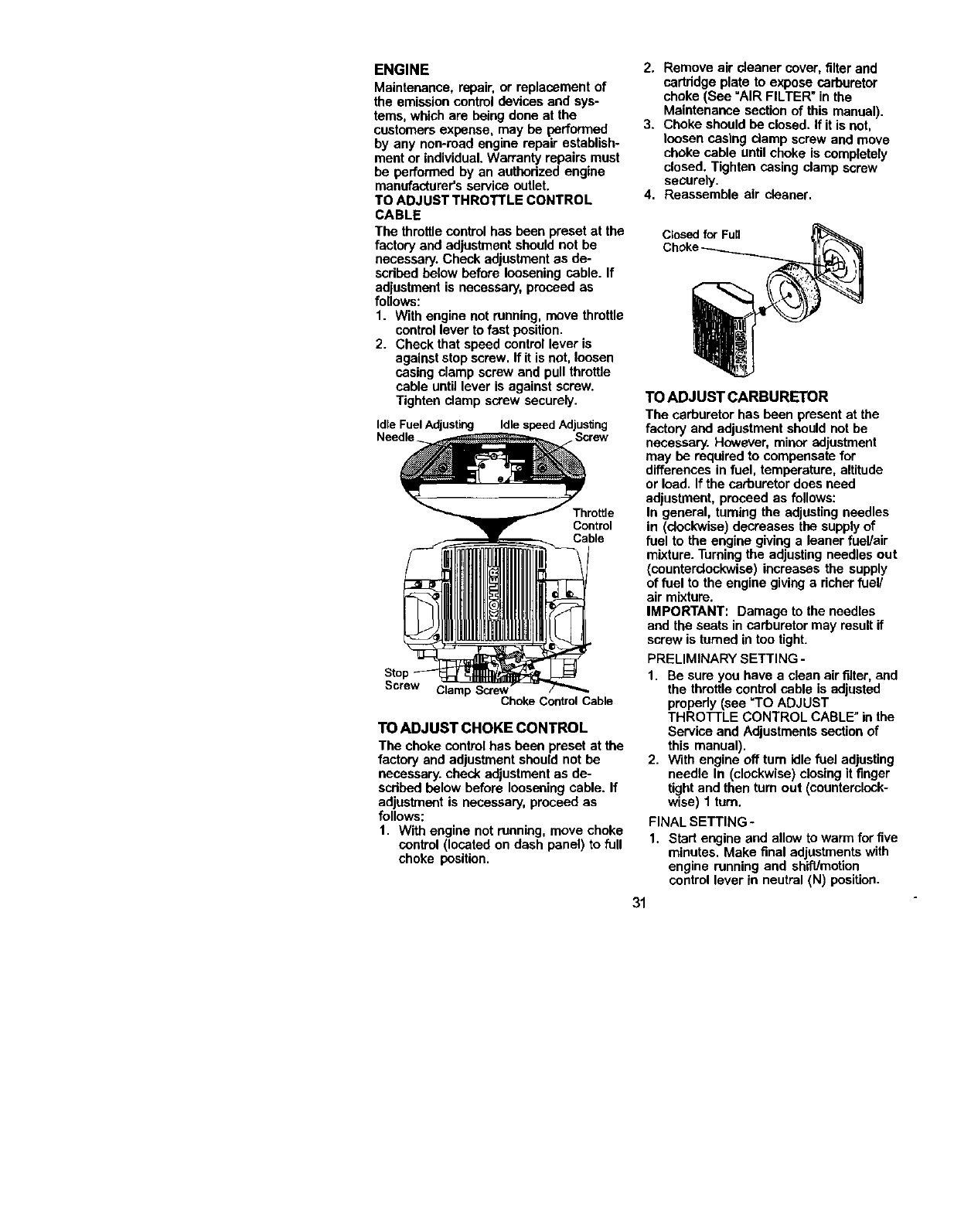

Idle Fuel Adjusting Idle speed Adjusting

Screw

Throttle

Control

Cable

Screw Clamp Screw

Choke Control Cable

TO ADJUST CHOKE CONTROL

The choke controlhas been preset at the

factory and adjustment should not be

necessary, check adjustment as de-

scribed below before loosening cable. If

adjustment is necessary, proceedas

follows:

1. With engine notrunning, move choke

control (located on dash panel) to full

choke position.

2. Remove air cleaner cover, filter and

cartridge plate to expose carburetor

choke (See =AIRFILTER" in the

Maintenance section of thismanual).

3. Choke shouldbe closed. If it is not,

loosen casing clamp screw and move

choke cable untilchoke iscompletely

closed. Tighten casing clamp screw

securely.

4. Reassemble air cleaner.

Closed for Full

TO ADJUST CARBURETOR

The carburetor has been present at the

factory and adjustment shouldnot be

necessary. However, minor adjustment

may be requiredto compensate for

differences in fuel, temperature, altitude

or load. If the carburetor does need

adjustment, proceed as follows:

In general, turning the adjusting needles

in (clockwise) decreases the supplyof

fuel to the engine giving a leaner fuel/air

mixture. Turningthe adjustingneedles out

(counterclockwise) increases the supply

offuel to the engine givinga richerfuel/

air mixture.

IMPORTANT: Damage to the needles

and the seats in carburetor may result if

screw is turned in too tight.

PRELIMINARY SETTING -

1. Be sure youhave a clean air filter, and

the throttlecontrol cable is adjusted

propedy (see =TOADJUST

THRO]3-LE CONTROL CABLE"in the

Service and Adjustments sectionof

this manual).

2. With engine off tum idle fuel adjusting

needle In (clockwise) closingit finger

tightand then turn out (counterclock-

wise) 1 tum.

FINAL SETTING -

1. Start engine and allow to warm for five

minutes. Make final adjustments with

engine running and shift/motion

control lever in neutral (N) position.

31