26

Section 4: Maintenance & Lubrication

WC1503 Wood Chipper 328-085M

Table of Contents

12/15/15

Helpful Operating Hints

The following hints will help protect against a plugged

discharge chute, plugged rotor housing, sheared

driveline bolt, and help keep the chipper running.

• Be careful not to feed too much product at once, feed

oversize product, feed wet product, or feed product too

fast. Doing so can plug the Wood Chipper.

• Alternate leafy material with a non leafy hardwood

piece. Hard wood pieces help clean out leafy material.

Keep alternating leafy material with hardwood pieces

until leafy material is processed.

• Let leafy branches dry for a couple weeks before

chipping them. Dry leaves will process better.

• Maintaining 1/32" gap between ledger bar and knives

will keep knives wiped off, prevent plugging, allow

product to feed better, and keep wood chipping.

Plugged Chutes & Rotor

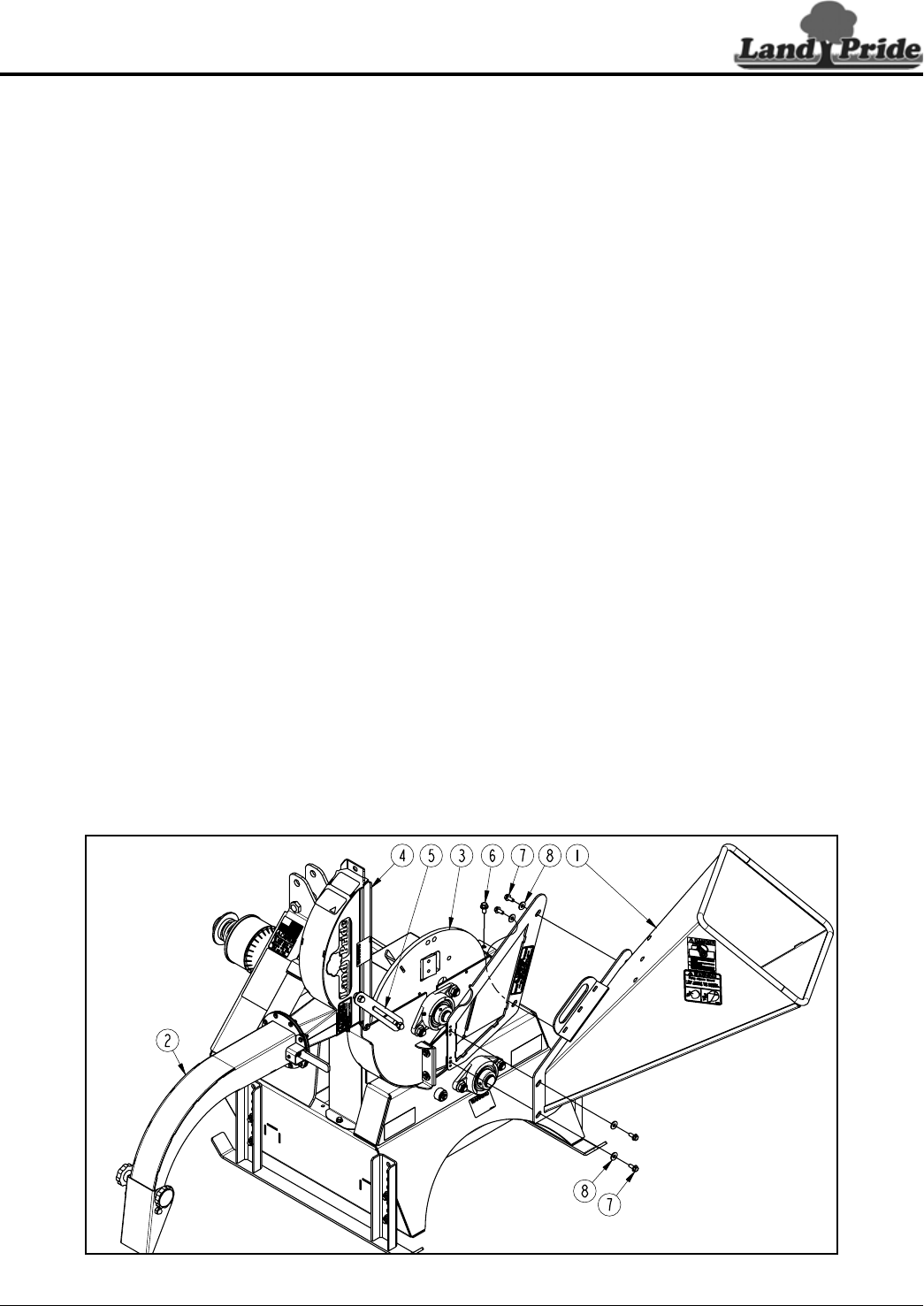

Refer to Figure 4-6:

Clear plugged chutes and rotor as follows:

1. Place gear selector in park, set park brakes,

disengage PTO, shut tractor engine off, remove

switch key, and wait for all moving parts to come to a

complete stop before working on this machine.

2. Disconnect driveline from tractor PTO shaft.

3. Unplug feed chute, discharge chute and rotor as

follows:

Unplug Feed Chute (#1)

a. Be sure to complete steps 1 & 2 above.

b. Pull all material out of feed chute. Make sure

nothing is jammed between inlet opening and

rotor at bottom of feed chute.

c. Loosen product jammed at the bottom with a stick

or board by prying it up and to the right.

d. If prying on product does not free it, then access

inlet opening by removing hex flange screws (#7),

flat washers (#8), and feed chute (#1).

e. Do not reattach feed chute (#1) until after

checking rotor for a plugged situation.

Unplug Rotor (#3)

a. Be sure to complete steps 1 & 2 on this page.

b. Remove hex flange screw (#6).

c. Rotate upper rotor housing (#4) up until locking

strap (#5) supports the housing.

d. Clean rotor housing of debris.

e. Manually rotate rotor to make sure all debris is

removed and rotor is not jammed.

f. Rotate rotor housing (#4) down and secure with

existing 3/8"-16 hex flange serrated screw (#6).

Tighten serrated screw to the correct torque.

Unplug Discharge Chute (#2)

a. Be sure to complete steps 1 & 2 on this page.

b. Make certain discharge chute (#2) is clean. Pull

material out of the discharge chute. If necessary,

use a stick to unplug a jam.

4. Reattach feed chute (#1) with existing 5/16"-18 x 3/4"

GR5 hex flange screws (#7) and flat washers (#8).

Tighten hex flange screws to the correct torque. See

“Feed Chute” on page 12 for detailed installation

instructions of feed chute.

5. Reattach driveline to tractor PTO shaft.

Accessing Rotor Knives

Figure 4-6

35263