21

Section 3: Adjustments

WC1503 Wood Chipper 328-085M

Table of Contents

12/15/15

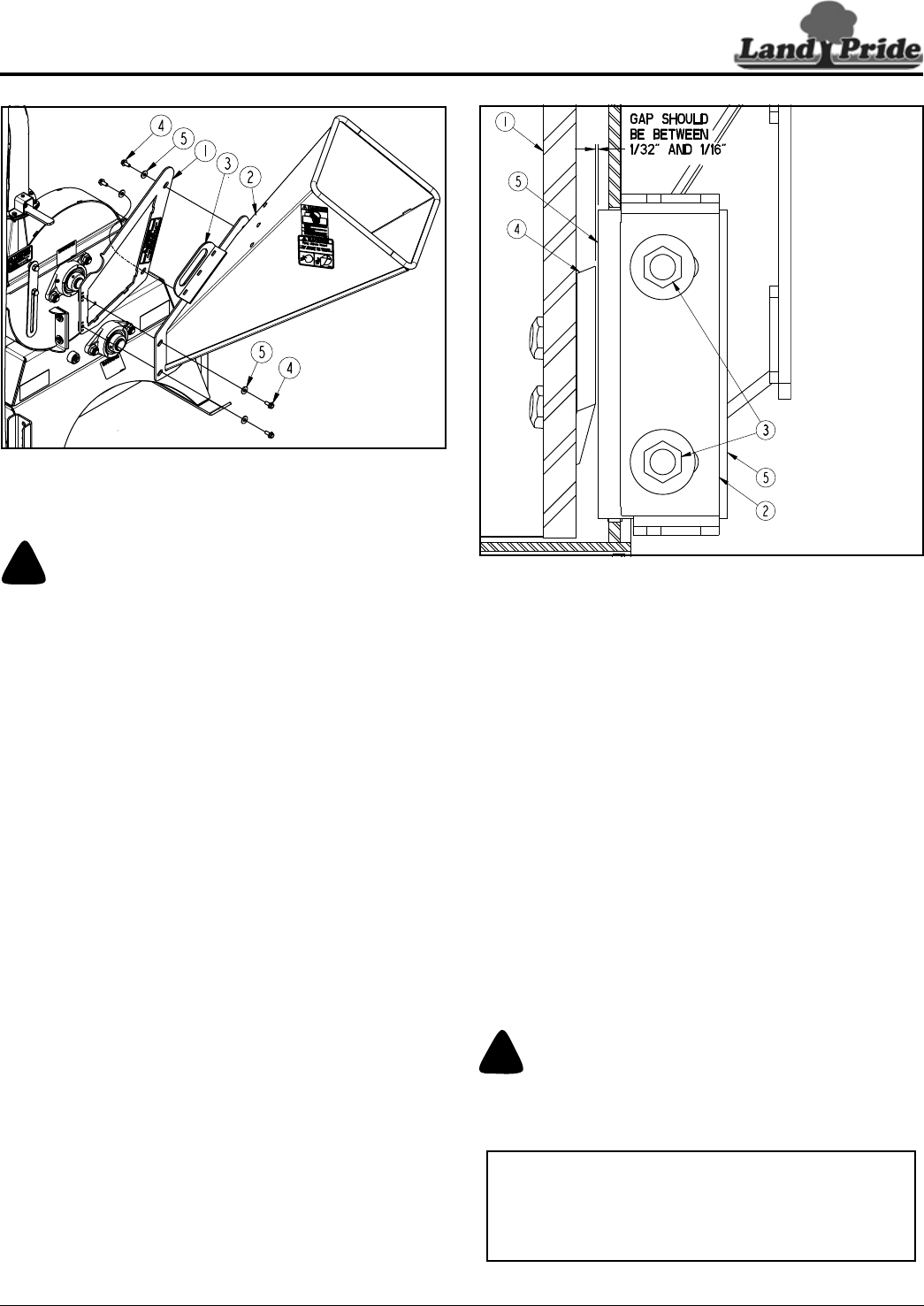

Cut Away View of Rotor (#4), Ledger (#5), and Knife (#4)

Figure 3-5

c. Repeat steps 4.a. & 4.b. above to realign the

second knife edge (#4) with ledger (#5). Go to

step 5 below if second knife edge is OK.

5. Make sure rotor housing is clear of all tools and loose

components that may have collected in the housing.

Refer to Figure 3-4:

6. Attach feed chute (#2) to inlet flange (#1) with

existing hex flange screws (#4) and flat washers (#5).

Tighten hex flange screws to the correct torque. See

“Feed Chute” on page 12 for detailed installation

instructions of feed chute.

7. Reconnect driveline to the tractor PTO shaft.

Adjust Knife Ledger Clearance

Refer to Figure 3-5 & Figure 3-6 on page 22:

See “Check Knife Ledger Clearance” on this page to

determine if gap between knife and knife ledger is OK.

If gap between knife and knife ledger is not OK, then

adjust knife ledger as follows:

!

CAUTION

Ledger bolts must be tightened to the correct torque value

provided under “Additional Torque Values” on page 34.

Not doing so can damage the chipper and cause bodily injury.

1. Loosen hex bolts (#3).

35259

NOTE: Credit card can be used to set gap.

Tolerances in manufacturing vary due to weld pull.

Set closest knife to ledger with 1/32" shim and lock

ledger in place. Rotate rotor and check other knives

for clearance.

Feed Chute Removal & Assembly

Figure 3-4

Check Knife Ledger Clearance

!

CAUTION

Knives are sharp. ALWAYS wear gloves and eye protection

while inspecting and adjusting ledger clearance.

Refer to Figure 3-5:

The knives cut best if knife ledger (#5) is adjusted with a

1/32" to 1/16" gap between cutting edge of knives (#4)

and knife ledger (#5). The larger the gap, the faster the

product will self-feed. Do not exceed 1/16" gap.

1. Make certain gear selector is in park and park brake

is set. Disengage PTO, shut tractor engine off,

remove switch key, and wait for all moving parts to

come to a complete stop before working on this unit.

2. Disconnect driveline from tractor PTO shaft.

Refer to Figure 3-4:

3. Remove hex flange screws (#4), washers (#5) and

feed chute (#2) to access inlet opening.

4. Check gap between knife ledger and cutting knives

as follows:

a. Refer to Figure 3-6 on page 22: Manually rotate

rotor (#1) until cutting edge of knife (#4) is in

alignment with knife ledger (#5).

b. Refer to Figure 3-5: Check gap between cutting

knife and ledger with a 1/32" gauge and again with

a 1/16" gauge.

• If the 1/32" gauge will not fit between knife and

ledger or if the gap between knife and ledger is

larger than 1/16", then the ledger needs to be

readjusted. See “Adjust Knife Ledger

Clearance” on this page for instructions.

• If the 1/32" gauge fits between ledger and knife

and the 1/16" gauge fits snug or does not fit at

all, then the gap is OK.

35252