24

Section 4: Maintenance & Lubrication

WC1503 Wood Chipper 328-085M

Table of Contents

12/15/15

Rotor Knife Maintenance

Refer to Figure 4-1 on page 23:

1. Manually rotate one of the rotor knives to the top.

2. Unscrew bolts (#5) and remove rotor knife (#6).

3. Rotate the other knife to the top and remove it.

4. Examine bolts (#5) and blades (#6) for damaged

threads and replace with Land Pride parts if needed.

5. Inspect knives for edge wear. Reverse knives if

unused edge is still sharp, resharpen knives if both

edges are worn, and replace knives if both edges

have been ground back so far that the gap between

the cutting edge and knife ledger is more than 1/16".

Reverse Knives

a. Flip knives over so that the sharp edges are

leading in rotation and reattach them with existing

3/8"-24 x 5/8" GR8 bolts (#5). See step 6 below

for special torque instructions.

Resharpen Knives

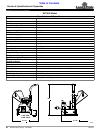

Refer to Figure 4-2:

a. Both knives should be sharpened at the same

original angle of 45

o

and must both be sharpened

at the same service time to maintain proper

balance. Take the following precautions when

sharpening knives.

• Always grind blades to a sharp 45

o

edge.

• Always grind cutting edge straight and

square (90

o

) to the knife’s side.

• Always keep corners of cutting edges square,

not rounded.

• Do not sharpen back side of cutting edge.

• Do not remove more material than necessary.

• Do not heat and pound out a cutting edge.

• Both blades should weigh the same.

b. Reattach knives to rotor (#1) with existing

3/8"-24 x 5/8" GR8 bolts (#5). See step 6 below for

special torque instructions.

Replace Knives With New Knives

Refer to Figure 4-1 on page 23:

a. If rotor knives have been reinstalled and knife

ledger cannot be adjusted to the proper

clearance, then replaced knives with new knives.

See “Check Knife Ledger Clearance” on page

21 for allowable clearance dimensions.

b. Reattach new knives to rotor (#1) with existing

3/8"-24 x 5/8" GR8 bolts (#5). See step 6 below for

special torque instructions.

6. Tighten GR8 knife bolts (#5) to 35-40 ft-lbs. See

“Additional Torque Values” on page 34 for more

information.

7. Adjust knife ledger to the proper clearance

dimensions. For detailed adjustment instructions,

see “Check Knife Ledger Clearance” on page 21.

8. Close upper rotor housing (#2). See step 5 under

“Rotor Knife Access” on page 23.

Sharpening Rotor Knives

Figure 4-2

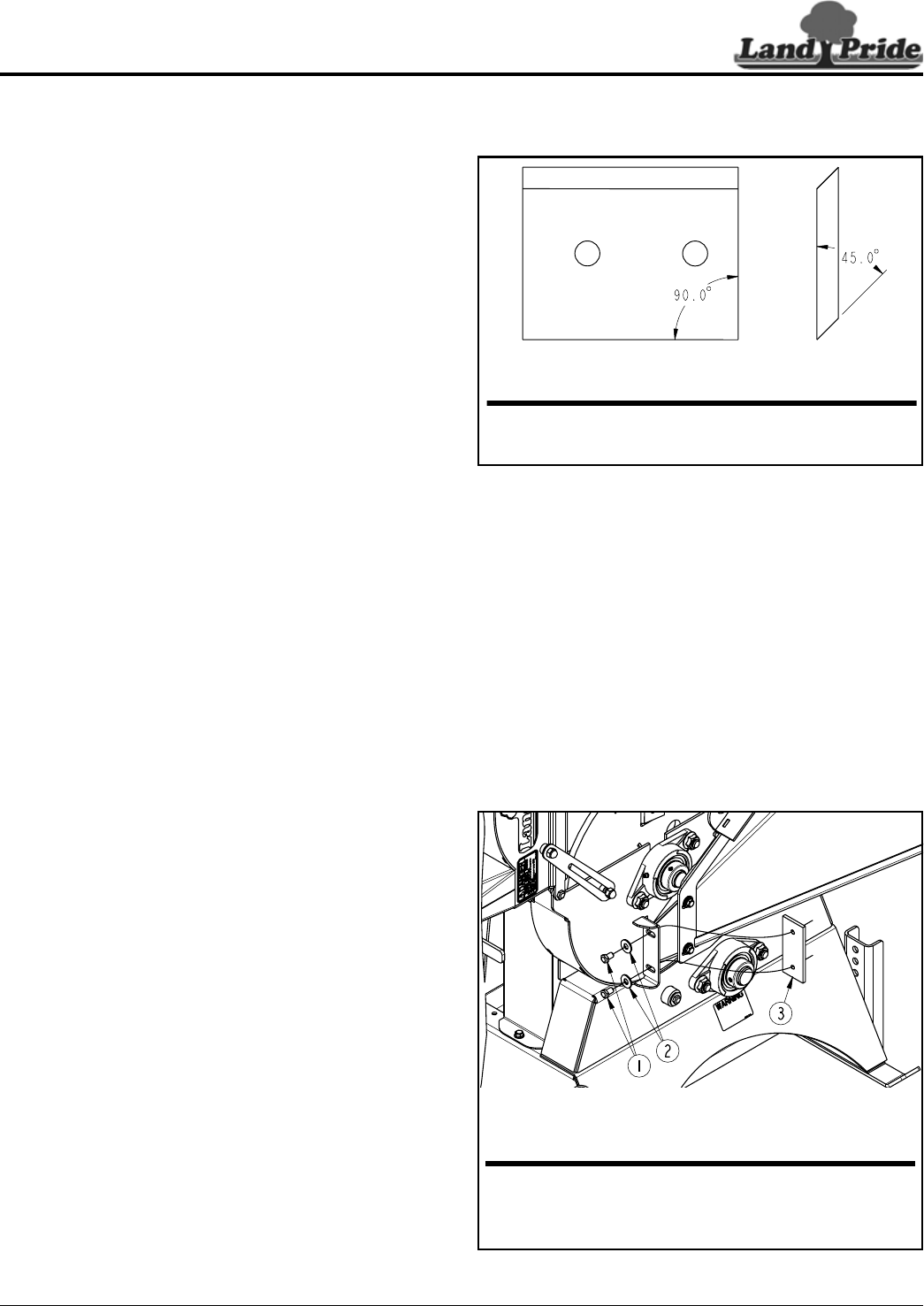

Knife Ledger Maintenance

Refer to Figure 4-3:

The knife ledger has four sharp edges. When an edge

becomes worn and dull or rounded, rotate knife ledger to

a new sharp edge.

1. Remove cap screws (#1), flat washers (#2), and knife

ledger (#3).

2. Rotate knife ledger (#3) to a new cutting edge and

reinstall with existing 3/8"-24 x 5/8" GR8 cap

screws (#1) and flat washers (#2).

3. Adjust knife ledger to the correct clearance. See

“Adjust Knife Ledger Clearance” on page 21.

Accessing Knife Ledger

Figure 4-3

Land Pride Rotor Knife & Bolt Part Nos.

Part No. Part Description

820-472C KNIFE REVERSIBLE - 17.5 ROTOR

802-961C HHCS 3/8-24X5/8 GR8 PLT

35258

Land Pride Knife Ledger Part No’s.

Item Part No. Part Description

1 802-961C HHCS 3/8-24X5/8 GR8 PLT

2 804-011C WASHER FLAT 3/8 USS PLT

3 820-476C KNIFE, LEDGER 3"

35302