11

Section 1: Assembly & Set-Up

WC1503 Wood Chipper 328-085M

Table of Contents

12/15/15

Section 1: Assembly & Set-Up

Tractor Requirements

Tractor horsepower rating is 12 to 30 hp. with a minimum

of 25 hp when operating at maximum capacity. Tractors

outside the horsepower range must not be used.

The rear power take-off (PTO) speed must be 540 RPM

maximum and have a 1 3/8”-6 spline PTO shaft.

A 3-Point Category I hitch is required. The lower 3-Point

arms must be stabilized to prevent side-to-side

movement. Most tractors have sway blocks or adjustable

chains for this purpose.

!

WARNING

Ballast weights may be required to maintain steering control.

Refer to your tractor’s operator’s manual to determine proper

ballast requirements.

Dealer Preparations

Make sure that the intended tractor conforms to the

“Tractor Requirements” stated above. Read and

understand the Operator’s Manual for this Wood Chipper.

An understanding of how it works will aid in its assembly

and setup.

Go through the Assembly Checklist before assembling

the Wood Chipper. Speed up your assembly task and

make the job safer by having all needed parts and

equipment readily at hand.

Torque Requirements

Refer to “Torque Values Chart” on page 34 to

determine correct torque values for common bolts.

Assembly Checklist

✔ Check Ref.

Make sure miscellaneous assembly tools are on hand:

Assortment of wrenches & sockets.

Have a minimum of two people available during assembly.

Check to see if ballast weights are needed.

See specifications for weight of Wood Chipper.

Page 30

Make sure all major components, driveline, and

loose parts are shipped with the machine. Refer

to section on “Assembly and Set-Up”.

Pages

11-15

Make sure all fasteners & pins are installed in

the correct location.

Refer to the Parts Manual if unsure.

Parts Manual

328-085P

Make sure all bolts are tight and cotter pins are

spread. Refer to “Torque Values Chart”

Page 34

Make sure all grease fittings are in place &

lubricated. Refer to “Lubrication Points”

Page 28

Make sure drive belts are aligned & tensioned.

Refer to “V-Belt Take-up”.

Page 22

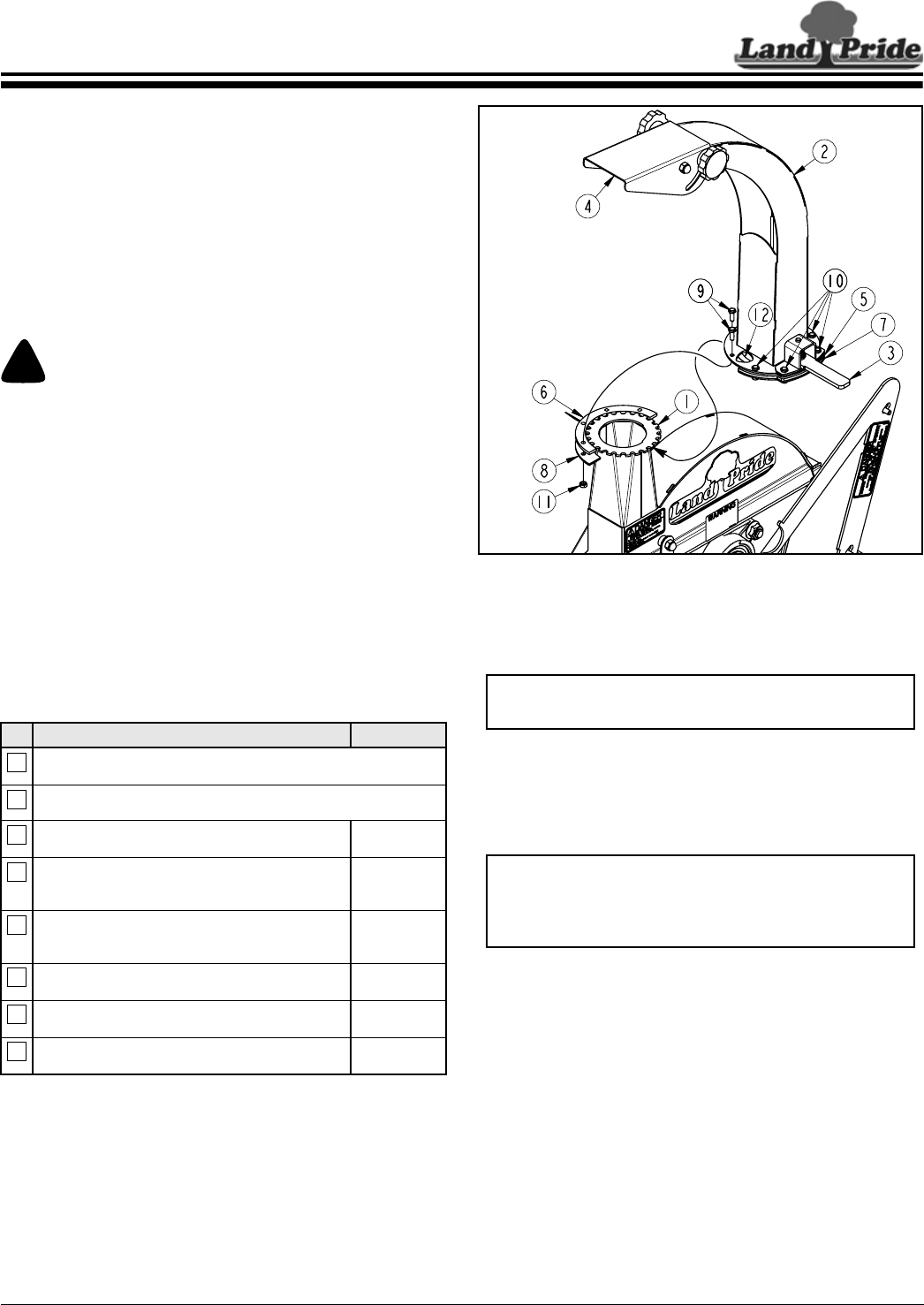

Discharge Chute Assembly

Figure 1-1

Discharge Chute

Refer to Figure 1-1:

1. Loosen the four rear bolts (#10) by two or three turns.

Do not remove bolts or nuts securing bolts.

2. Remove the front four bolts (#9), half-clamp

plate (#8), and half-spacer plate (#6) from discharge

spout (#2). Keep hardware for reuse.

3. Make sure bottom half-clamp plate (#7) is positioned

against underside of notched plate (#1). Being

careful not to damage plastic bearing (#12), slide

front of discharge chute (#2) onto notched plate (#1)

until discharge chute is centered over the notched

plate.

4. Place half-spacer plate (#6) on top of half-clamp

plate (#8) with bolt holes in alignment with each

other.

5. Position bottom half-clamp plate (#8) against

underside of notched plate (#1) as shown.

6. Bolt chute (#2) to half-spacer plate (#6) and half-

clamp plate (#8) with the four removed 1/4”-20 x 3/4"

GR5 cap screws (#9) and hex lock nuts (#11).

7. Draw all eight hex lock nuts (#11) up snug and then

back each one off 1/2 turn.

35251

NOTE: Half-clamp plate (#8) and half-spacer

plate (#6) are shipped bolted to discharge spout (#2).

IMPORTANT: Be careful not to damage plastic

bearing attached with adhesive to underside of

discharge chute while attaching chute to the

chipper’s notched plate.