13

Section 1: Assembly and Set-up

9/24/08

RCR2684 Rotary Cutter 312-785M

Land Pride

Table of Contents

Driveline Installation

If the Rotary Cutter is to be used on more than one

tractor, an additional driveline may be required especially

if a quick hitch is used.

!

CAUTION

Do not use a PTO adaptor. A PTO adapter will increase strain

on the tractor’s PTO shaft resulting in possible damage the

shaft and driveline.

!

CAUTION

Tractor PTO shield and all Rotary Cutter guards must be in

place at all times during operation!

!

CAUTION

Always engage parking brake, shut off tractor and remove key

before dismounting from tractor.

!

WARNING

Damaged drivelines can cause serious injury or death.

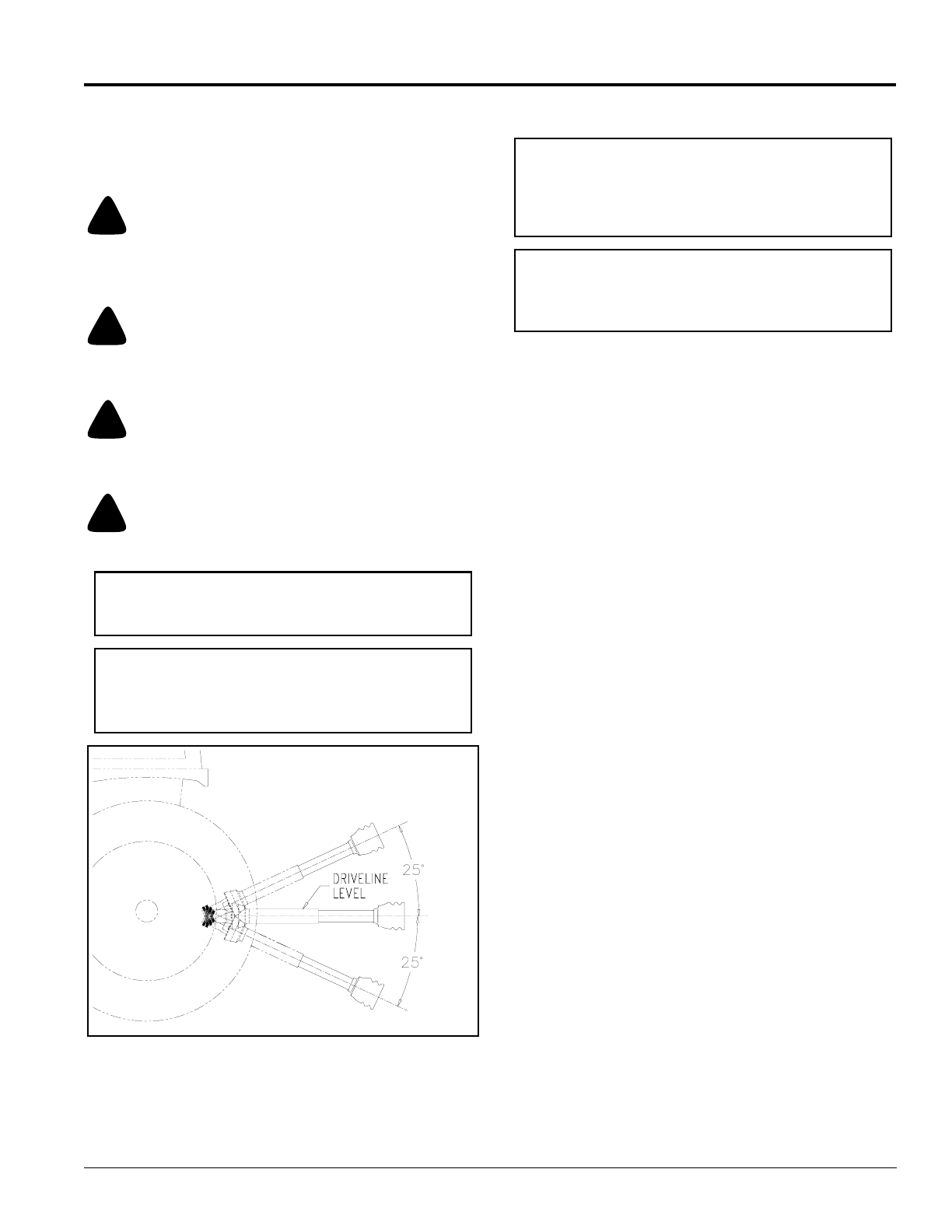

Maximum PTO Driveline Movement During Operation

Figure 1-10

IMPORTANT: Some tractors are equipped with

multispeed PTO ranges. Be certain your tractor ‘s

PTO is set for 540 rpm.

IMPORTANT: Avoid premature driveline

breakdown. A driveline that is operating must not

exceed an angle of 25 degrees up or down while

operating the 3-point lift. See Figure 1-10 below.

24872

Driveline Minimum Length

Refer to Figure 1-11 on page 14:

1. Obtain the shortest distance possible between

tractor PTO shaft and gearbox shaft by starting the

tractor and slowly engaging 3-point lift to move the

lower arms up or down until the gearbox shaft is

aligned and level with the tractor's PTO shaft.

Securely block cutter deck in this position.

2. Place tractor gear selector in park, shut tractor

engine off, set park brake and remove switch key.

3. Attach driveline to cutter and tractor as follows:

a. Remove gearbox shaft cover (#8). (See Figure 1-

9 on page 12.)

b. Slide inner yoke of driveline over the gearbox

shaft and secure with locking collar.

c. Slide outer yoke of driveline over the tractor's PTO

shaft and secure with locking collar.

d. Skip to step 5 on page 14 if driveline fits between

tractor and Rotary Cutter.

4. The driveline will require shortening if it is too long to

fit between the tractor and Rotary Cutter. Shorten

driveline as follows:

a. Check to make sure cutter and tractor PTO shafts

are level with each other and the deck is securely

supported at this height with support blocks.

b. Pull driveline profiles apart into two sections as

shown in Figure 1-11.

c. Attach outer driveline universal joint to tractor

PTO shaft and inner driveline universal joint to

gearbox shaft. Pull on each driveline section to be

sure universal joints are secured.

d. Hold driveline sections parallel to each other to

determine if they are too long. The inner and outer

shields on each section should endapproximately

1" short of reaching the universal joint shield on

the adjacent section (see “B” dimension). If they

are too long, measure 1" (“B” dimension) back

from the universal joint shield and make a mark at

this location on the inner and outer shields.

e. Cut off inner shield at mark (“X” dimension). Cut

same amount off inner shaft (“X1” dimension).

Repeat cut off procedure (“Y”&“Y1” dimensions)

to cut outer driveline half.

f. Remove all burrs and cuttings.

IMPORTANT: Always check driveline minimum

length during initial setup, when connecting to a

different tractor and when alternating between using

a quick hitch and a standard 3-point hitch. More than

one driveline may be required to fit all applications.

IMPORTANT: It is necessary to align and level the

tractor’s PTO shaft with the gearbox shaft when

checking driveline minimum length. Too long a

driveline can damage tractor, gearbox and driveline.