14

Section 1: Assembly & Set-up

RCF2784 Rotary Cutters 326-364M

12/15/15

Table of Contents

Check Driveline Maximum Length

Refer to Figure 1-7:

The driveline maximum allowable length must, when fully

extended, have a minimum overlap of profile tubes by not

less than 1/2 the free length with both inner and outer

profile tubes being of equal length.

1. Apply multi-purpose grease to the inside of the outer

shaft and reassemble the driveline.

2. Assemble the two driveline profiles together with just

1/2 overlapping of the profile tubes as shown. Once

assembled, measure and record maximum allowable

length here. ________

Driveline Maximum Extended Length

Figure 1-7

3. Continue with “Check Driveline Interference” on

right side of this page.

Check Driveline Interference

1. Make certain driveline yokes are properly attached.

2. Start tractor and raise Rotary Cutter just enough to

remove support blocks from under the cutter.

3. Slowly engage tractor hydraulic 3-Point control lever

to lower cutter while checking for sufficient drawbar

clearance. Move drawbar ahead, aside, or remove if

required.

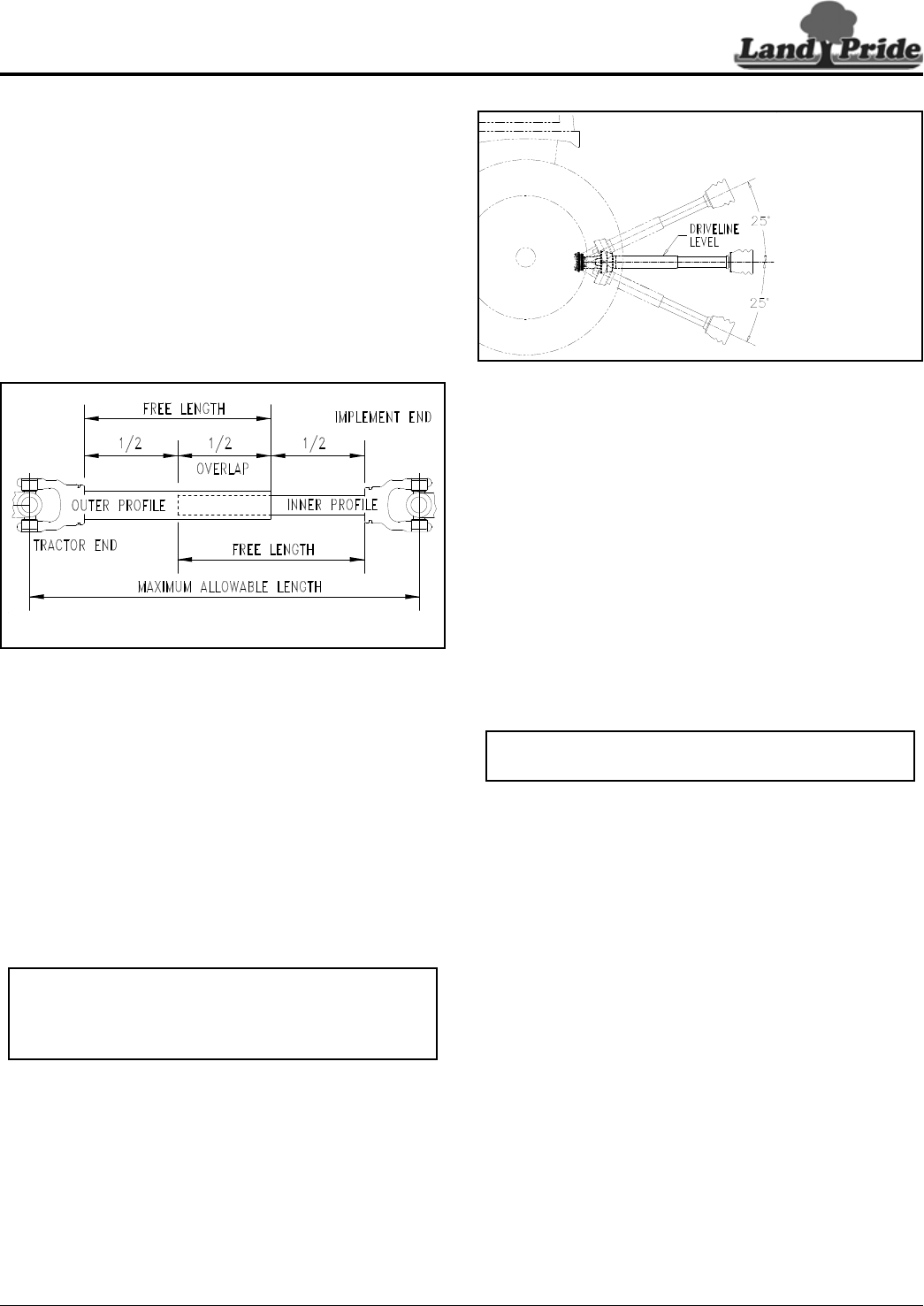

Refer to Figure 1-8:

4. With PTO off, raise implement fully up to make the

following checks below. If driveline exceeds any of

the limits listed, set tractor 3-Point lift limiter at a

height that will keep the driveline within its lift limits

and to avoid premature driveline breakdown.

• Driveline does not exceed 25

o

up.

• Driveline does not exceed maximum allowable

length recorded in step 2 under “Check Driveline

Maximum Length”.

24804

Outer Shielding has been removed for clarity.

IMPORTANT: Avoid premature driveline breakdown.

A driveline that is operating must not exceed an

angle of 25 degrees up or down while operating 3-

point lift.

Maximum PTO Driveline Movement During Operation

Figure 1-8

Pull-Type Cutter Assembly & Set-up

The following instructions are for assembling the

Pull-Type cutter. See page 9 for “3-Point Cutter

Assembly & Set-up” instructions.

Hitch Assembly

The tongue, drivelines, dual tailwheel axle, and ratchet

jack option or hydraulic cylinder option will need to be

assembled to the deck.

Refer to Figure 1-9 on page 15:

1. Discard 2 1/2" long bushing (not shown) shipped with

hitch pins (#1). Attach tongue (#7) to deck with hitch

pins (#1) and 1" long spacers (#4). Secure hitch pins

with linchpins (#21).

2. With bearing lock collar facing driveline (#25), attach

bearing support assembly (#5) to tongue (#9) with

bushings (#6), flat washers (#18), lock washer (#19),

hex nut (#15), and 5/8"-11 x 7 1/2" GR5 hex head cap

screw (#10). Tighten hex nut to the correct torque.

3. Attach spring hose loop mounting bracket (#3) to the

right-hand clevis with 3/8" -16 x 1" GR5 hex head cap

screw (#11) and lock nut (#16). Tighten lock nut to the

correct torque.

4. Attach spring hose loop (#22) to spring hose loop

mounting bracket (#3) with 3/8" -16 x 1" GR5 cap

screw (#9), flat washer (#17), and lock nut (#13)

Tighten lock nut to the correct torque.

5. Attach parking jack support stob (#2) to the left-hand

clevis lower hole with 3/4"-10 x 1 3/4" GR5 hex head

cap screw (#12) and lock nut (#16). Tighten lock nut

to the correct torque.

6. Attach parking jack (#27) to stob on tongue with

detent hitch pin (#28). Make certain detent hitch pin

is fully inserted.

24872

IMPORTANT: Be sure bearing lock collar in bearing

support assembly (#5) is facing driveline (#25).