37

Section 5: Maintenance & Lubrication

ZSR54, & ZSR60 Accu-Z Razor

®

Zero Turn Mowers 357-344M

Table of Contents

12/15/15

9. Remove top port plug (#4). This will allow the

transaxles to vent during oil fill.

10. Fill transaxle with oil by adding oil to the expansion

tank (#7) until oil appears at the top port opening

(approximately 2 qts.). See page 50 for transaxle oil

specifications.

11. Install top port plug (#4) and tighten to 180 in-lbs.

12. Continue to add oil to the expansion tank until oil

reaches the full cold line (approximately 1/2" up from

the bottom of the tank).

13. Reinstall expansion tank cap (#7) by hand. Be

careful to not over-tighten.

14. Wipe off all excess oil. A degreaser may be needed to

remove excess oil.

15. Repeat steps 1 to 14 for the right side.

Transaxle Purging Procedures

It is critical that air is purged from the hydrostatic drive

system to keep it efficient. This is because compression

and expansion rate of air is higher than that of oil.

This purge procedure should be implemented any time

the hydrostatic system has been opened to facilitate

maintenance or after the oil has been changed.

Symptoms of a hydrostatic system that has not been

purged may be:

1. Noisy operation.

2. Lack of power after short term operation.

3. High operation temperature and excessive

expansion of oil.

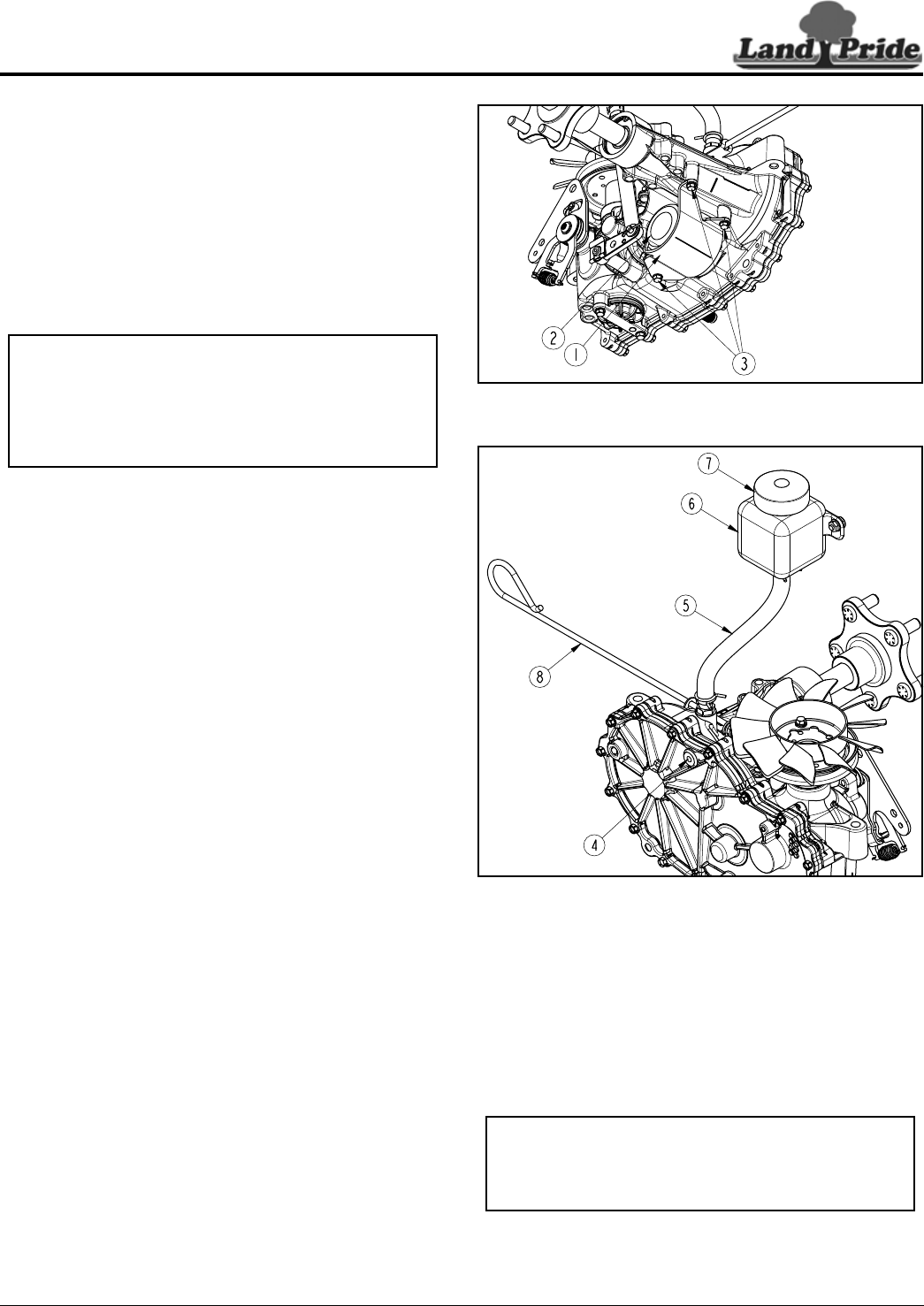

Refer to Figure 5-11:

Before purging system, make sure fill tubes (#10) are full

of oil and expansion tanks (#11) are filled to the cold full

line. Squeeze all air from fill tubes and add oil if

expansion tanks are low. See page 50 for transaxle oil

specifications. The following procedures are best

performed with mower drive wheels off the ground and

then repeated under normal operating conditions. If this

is not possible, the procedure should be performed in an

open area free of any objects or bystanders.

1. Open both transaxle bypass valves by pulling out on

the bypass valve rods (#13) and lifting them into the

slot to lock them in position. Bypass valve rods are

located at the rear of the engine platform.

2. Start the engine and place both control levers in

neutral. Slowly move the control levers completely

forward and reverse 5 to 6 times.

NOTE: The fill tube (#5) should be hand squeezed

several times to burp out air and to drain oil from the

expansion tank into the tube. Be careful not to

damage the tube while squeezing it. Use a

protective cloth wrapped around the tube if using a

tool to squeeze such as a pair of pliers.

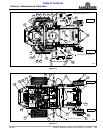

Left Transaxle (View of Oil Filter)

Figure 5-10

Left Transaxle (Inboard View)

Figure 5-11

3. Close both bypass valves by pulling back on the rods,

lowering them down and slowly releasing them to

allow the springs to pull back on the rods.

4. With engine running and control levers in neutral,

slowly move levers forward and reverse 5 to 6 times.

5. Stop engine and check fill tubes (#10) and expansion

tanks (#11). Squeeze all air from fill tubes and add oil

if expansion tanks are low.

6. It may be necessary to repeat Steps 1 to 5 until all air

is completely purged from the system and the

transaxle operates at normal noise levels and travels

at normal speeds.

27804

27805

IMPORTANT: The transaxle is considered purged

when transaxles are at the proper oil level, operate

at normal noise levels, oil temperatures are not

excessively high, and mower does not lack power.