PRELIMINARY ROUGH-IN

The floor structure beneath the unit must be able to

support a total weight of the unit and bather(s).

Refer to page 2, SPECIFICATIONS, for weight speci-

fications. Refer to COMPONENT IDENTIFICATION

on page 4 to help identify parts.

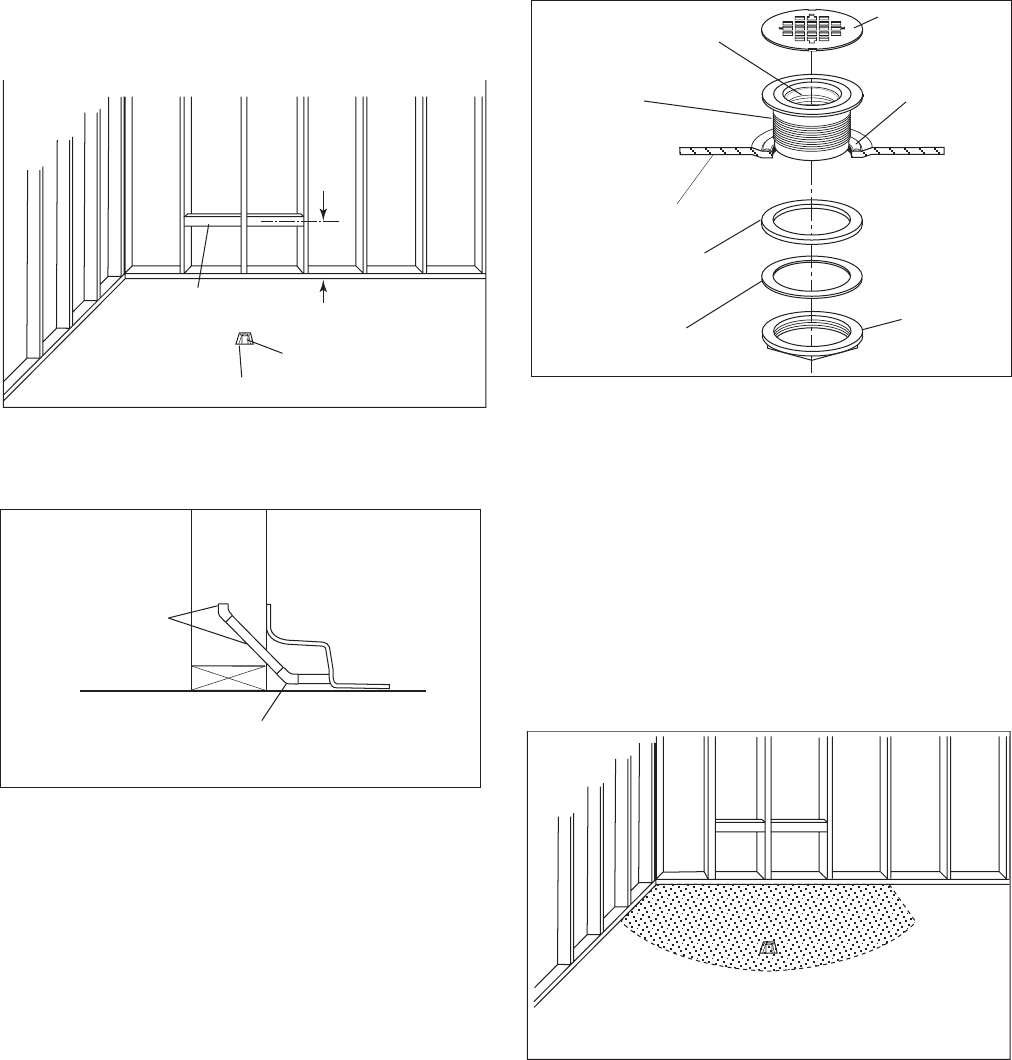

STEP 1

Provide an opening in the subfloor no less than 5" x 5"

square. This opening should be located on the center

lines of the shower base drain hole.

Install blocking in studwall for seat flange.

STEP 2

Remove the stainless steel strainer from the drain

assembly. Disassemble the locknut and two gaskets

from the back of the drain assembly. Apply a 1/4" bead

of caulking (silicone) to the drain hole and insert the drain

assembly. Replace the rubber washer, fiber washer,

and lock nut in that order. Hand tighten the locknut.

Remove excess sealant from finished side.

Apply a lubricant (common household liquid soap

works well) to the inside of the rubber seal of the drain

assembly.

STRAINER

DRAIN

ASSEMBLY

SILICONE

SEALANT

SHOWER BASE

RUBBER WASHER

FIBER WASHER

NUT

APPLY LUBRICANT

BASE INSTALLATION

INSTALLATION INSTRUCTIONS

STEP 3

If the subfloor is level, no other preparation is neces-

sary. You can proceed to install the shower base. If the

subfloor is not level, level the subfloor by spreading floor

leveling compound, mortar, plaster or minimal expan-

sion structural foam with a minimum density of 5 lbs/

cubic feet EVENLY over ENTIRE area where base will

be installed. The compound used MUST make contact

with the entire bottom surface of the base. Both sides of

a joint or splice of subfloor should be level to each other.

Level and support waste pipe cutout area greater than 5"

x 5". The base is NOT to be supported by the tile flange.

SPREAD MORTOR OR LEVELING

COMPOUND ETC EVENLY OVER ENTIRE AREA

45° COPPER ELBOW

PROVIDED (2)

COPPER FITTINGS

AND TUBING

NOT PROVIDED

STUD

WALL

DETAIL 1

5"x5" OPENING (MIN. AS POSSIBLE)

2" WASTE PIPE

21"

C

L

BLOCKING

5

Jacuzzi Whirlpool Bath

©

BZ00000 03/05

CAUTION: A nonflammable protective barrier must

be placed between soldering work and base unit to

prevent damage to the base.

WATER SUPPLY ROUGH-IN