Maintenance

Lubricate Grease Fittings

Note: See chart for service intervals.

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Lubricate ttings with NGLI grade #2

multi-purpose gun grease.

Refer to the following chart for tting locations

and lubrication schedule.

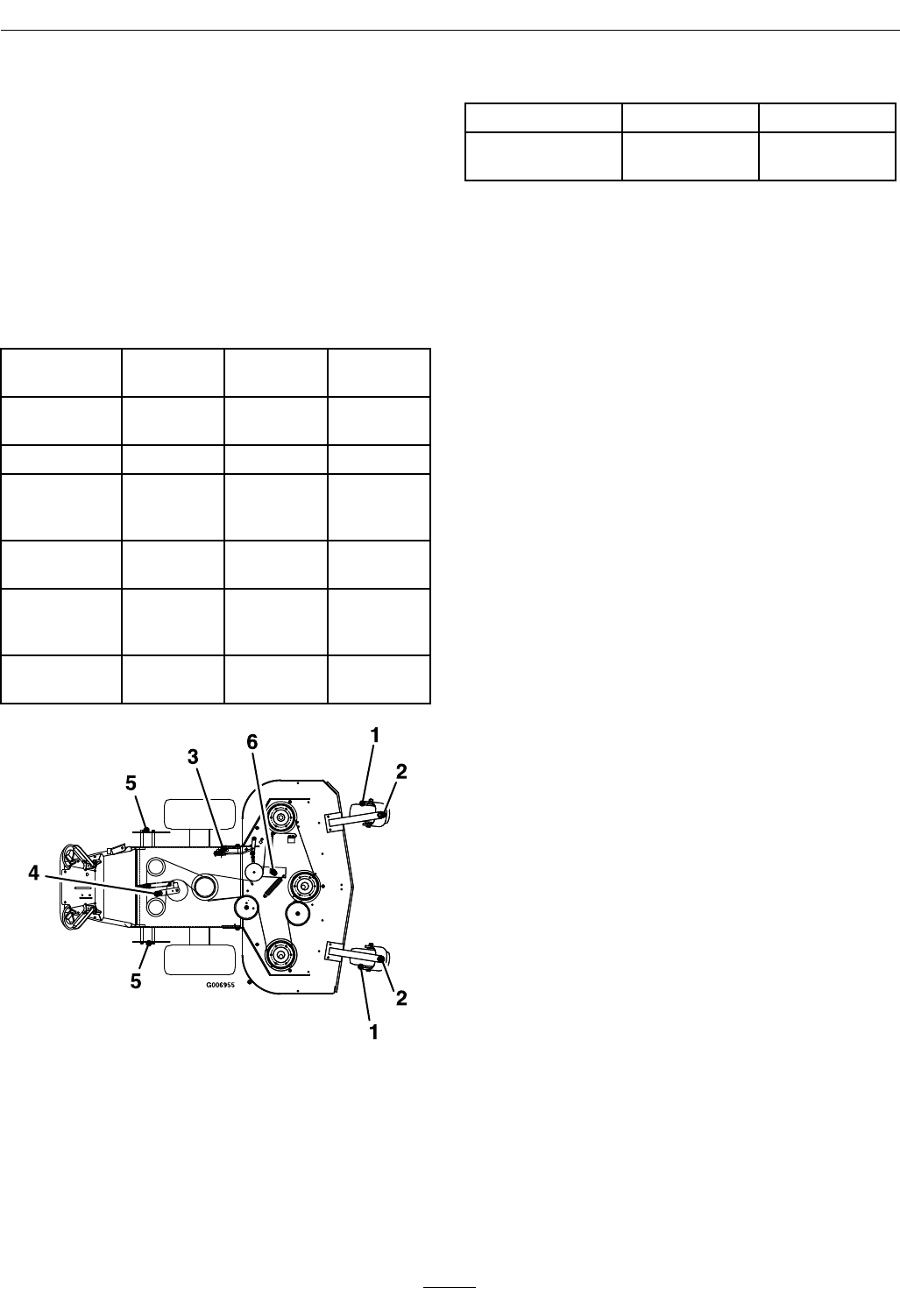

Lubrication Chart

Fitting

Locations

Initial

Pumps

Number of

Places

Service

Interval

1. Caster Wheel

Bearings

12 2

Daily

2. Caster Pivots

2 2

Daily

3. PTO

Engagement

Bellcrank

1 1

Monthly

4. Pump Drive

Idler Pivot

2 1

40 hours

5. Pump

Control

Bearings

2 2

40 hours

6. Mower Deck

Idler Pivots

2 1

40 hours

Number 4 Idler Pivot (Pump Drive) Located

under engine deck

Number 4 and 6 (Idler Pivots) Disassemble and grease

once a month under a “No Load” condition.

3. Lubricate pivot points with a spray penetrating

lubricant as shown in the Spray Lubricant Chart.

Spray Lubricant Chart

Spray Lubricant Chart (cont'd.)

Pivot Point

Number of Places

Service Interval

1. PTO Engagement

Upper Bellcrank

1

40 hours

Check Spark Plugs

Service Interval: Every 160 hours

Remove spark plugs, check condition and reset gaps,

or replace with new plugs. See Engine Owner’s

Manual.

Change Fuel Filter

Service Interval: As required

A fuel lter is installed in the fuel line between the

fuel tank and the engine. Replace when necessary.

Change Hydraulic System

Filter

Service Interval: After the rst 250 hours

Every 500 hours/Yearly

(whichever comes

rst) thereafter

(Every 250 hours/Yearly if

using Mobil 1 15W50)

Note: Use only Exmark Part No. 109–4180 for

Summer use above 32°F (0°C) or P/N 1-523541 for

Winter use below 32°F (0°C) (Refer to Transmission

section in Specications for lter specications).

1. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2. Carefully clean area around lter. It is important

that no dirt or contamination enter hydraulic

system.

3. Unscrew lter to remove and allow oil to drain

from reservoir.

Important: Before reinstalling new lter, ll

it with Exmark Premium Hydro oil and apply

a thin coat of oil on the surface of the rubber

seal.

Turn lter clockwise until rubber seal contacts the

lter adapter, then tighten the lter an additional

2/3 to 3/4 turn.

24