MAINTENANCE

MAINTENANCE

SR20M/SR14M 04/94 Maintenance Section 5-2

© 2004 Alamo Group Inc.

Before operating your Rotary Cutter, make sure it is properly lubricated and thoroughly inspected. Only a

minimum of time and effort is required to regularly lubricate and maintain this machine to provide long life

and trouble free operation.

WARNING Always disengage the PTO before raising the Rotary Cutter for transporting or making

adjustments.

LUBRICATION INFORMATION

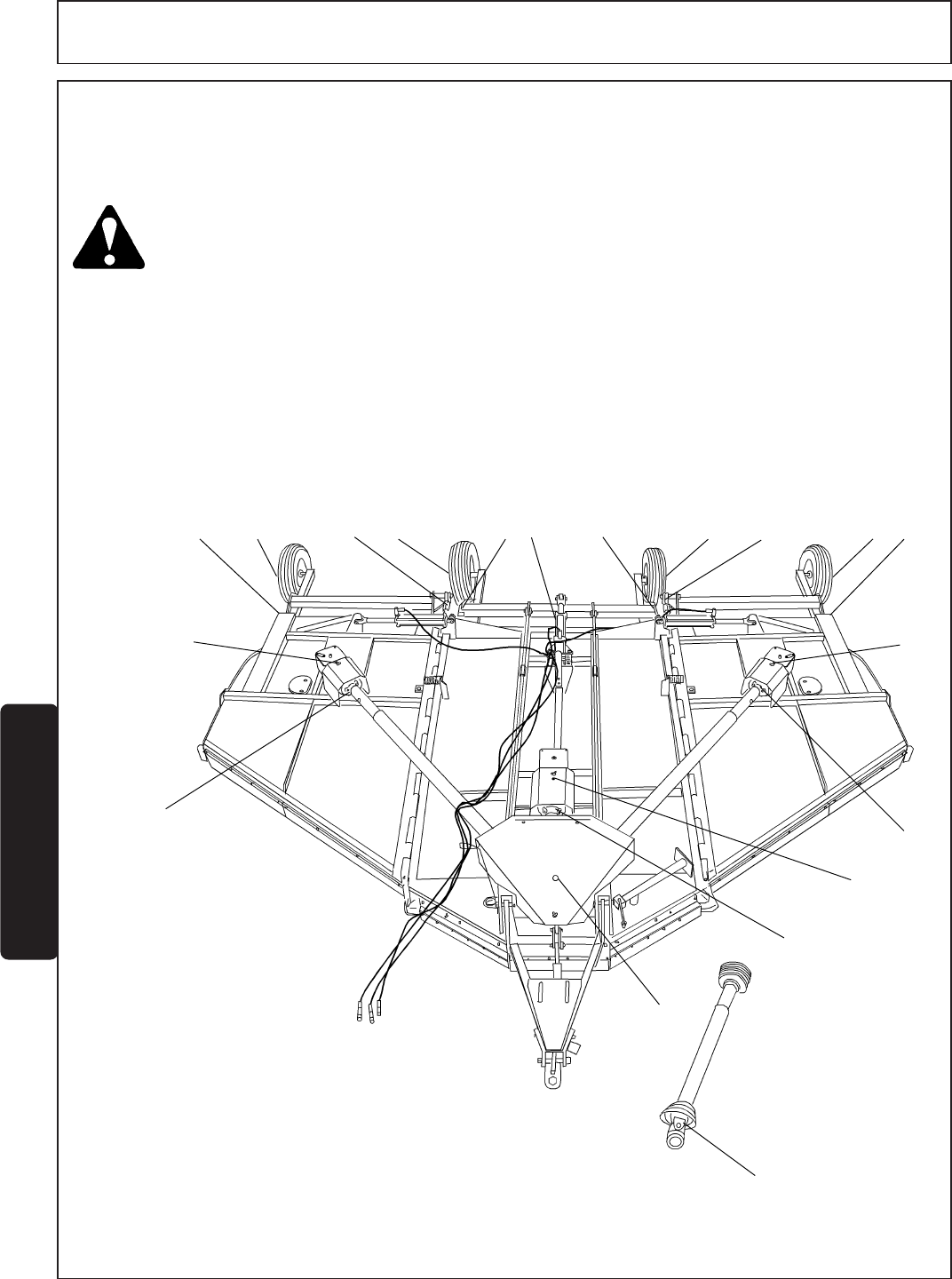

Do not let excess grease collect on or around parts, particularly when operating in sandy areas. The

accompanying illustration shows lubrication points. The chart gives the frequency of lubrication in hours,

based on normal operating conditions. Severe or unusual conditions may require more frequent lubrica-

tion. FIGURE 1.

Use an SAE multi-purpose, lithium-type grease for all locations shown except location #2 use lubricant

NLGI 000 Grease (P/N 000769030). Be sure to clean the fitting thoroughly before using grease gun. Daily

lubrication of the wing driveline slip joint is necessary. Failure to maintain proper lubrication will result in

damage to U-joints, gearbox, and/or driveshaft.

Lubrication Fitting Location

ITEM DESCRIPTION FREQUENCY

1 U-Joints 8 hours

2 Gearbox Check daily

3 Divider Gearbox Check daily

4 Axle Adjustment Rod 8 Hours

5 Wheel Hubs Weekly

6 Axle Pivot Points 8 hours

FIGURE 1

6

6655 5 564 4

3

1

1

1

1

2

2

2