OPERATION

OPERATION

Operation Section 4-21

© 2004 Alamo Group Inc.

SR14/SR20 10/03

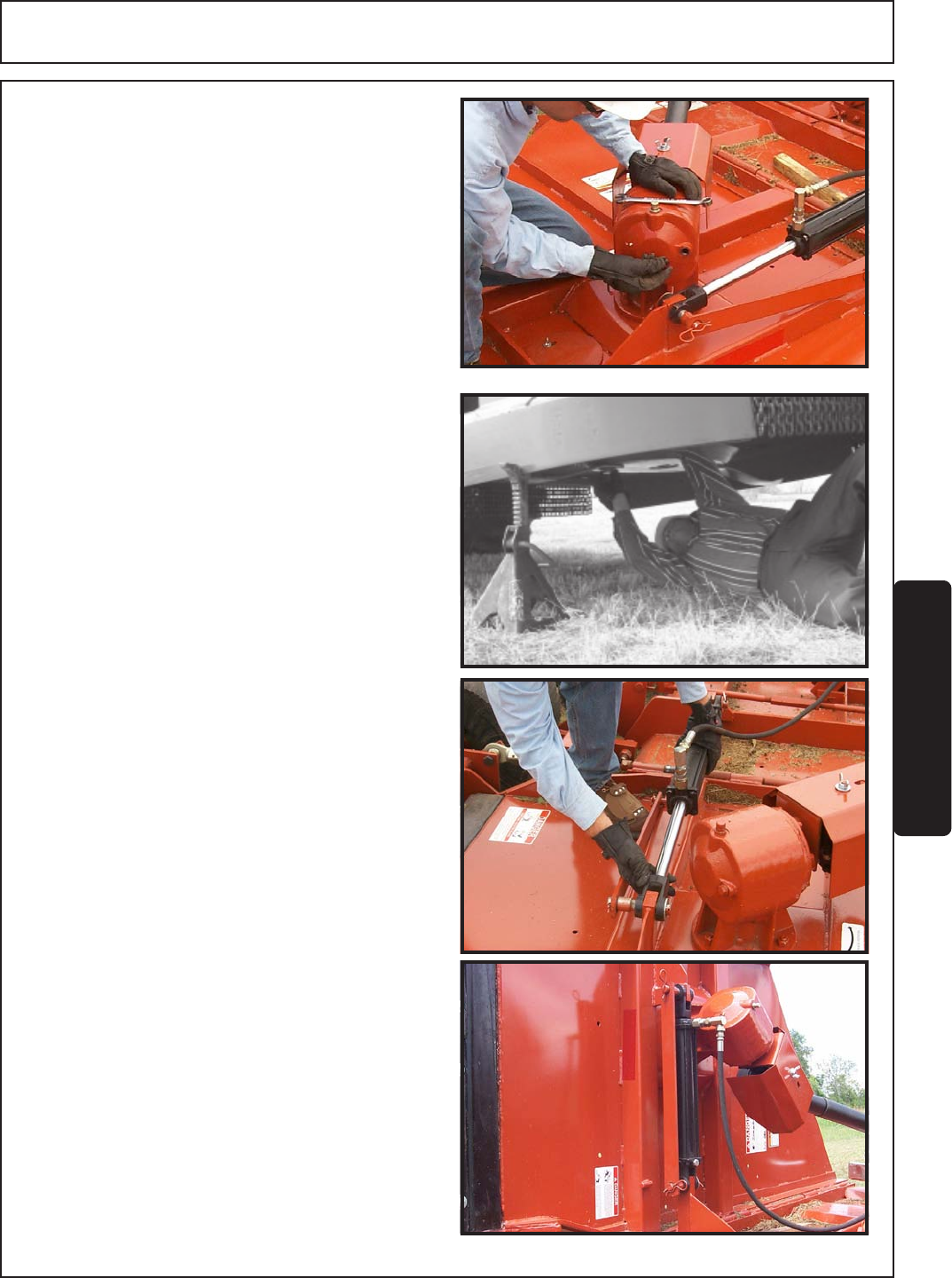

¾ Ensure each hydraulic cylinder is installed and

retained correctly. Ensure the proper size pins

are used to retain the cylinders in place and are

secured with pins.

¾ Check for hydraulic oil leaks on the cylinders, along

the hydraulic lines, and at tractor hydraulic ports.

IMPORTANT: DO NOT use your hands to check

for oil leaks. Use a piece of heavy paper or

cardboard to check for hydraulic oil leaks.

¾ Perform scheduled lubrication as specified in the

maintenance section.

¾ Inspect each gearbox oil level and replenish if

needed. A low oil level is a warning sign that the

gearbox may be cracked or its seal is damaged

and needs to be replaced.

¾ Ensure all gearbox vents are in place and free from

clogs.

¾ Ensure that the mower is equipped and secured

with wing brace supports.

¾ Check the condition of the wing hinge pins.

¾ Check the condition of the mower axle suspension

spring.

¾ Inspect mower tire condition, wheel bearings, and

lug nut torque.

¾ Inspect blades and blade bolts for looseness and

excessive wear. Make sure the mower is securely

blocked up before crawling beneath. Replace

damaged, worn, and missing blades as complete

sets to maintain rotary balance.

¾ Ensure carrier hub nuts are tightened with the cotter

pin inserted and spread.

¾ Inspect the condition of the deck skid shoes and

the skid shoe attaching hardware.