Assembly 23

MAN0458 (9/23/2005)

ASSEMBLY INSTRUCTIONS

DEALER SET-UP INSTRUCTIONS

Assembly of this chipper is the responsibility of the

Woods dealer. If should be delivered to the owner

completely assembled, lubricated, and adjusted for

normal chipping conditions.

Assembly will be easier if parts are aligned and loosely

assembled before tightening hardware. Recommended

torque values for hardware are located in the Bolt

Torque Chart, page 35.

Complete check lists on page 27 when you have

completed the assembly.

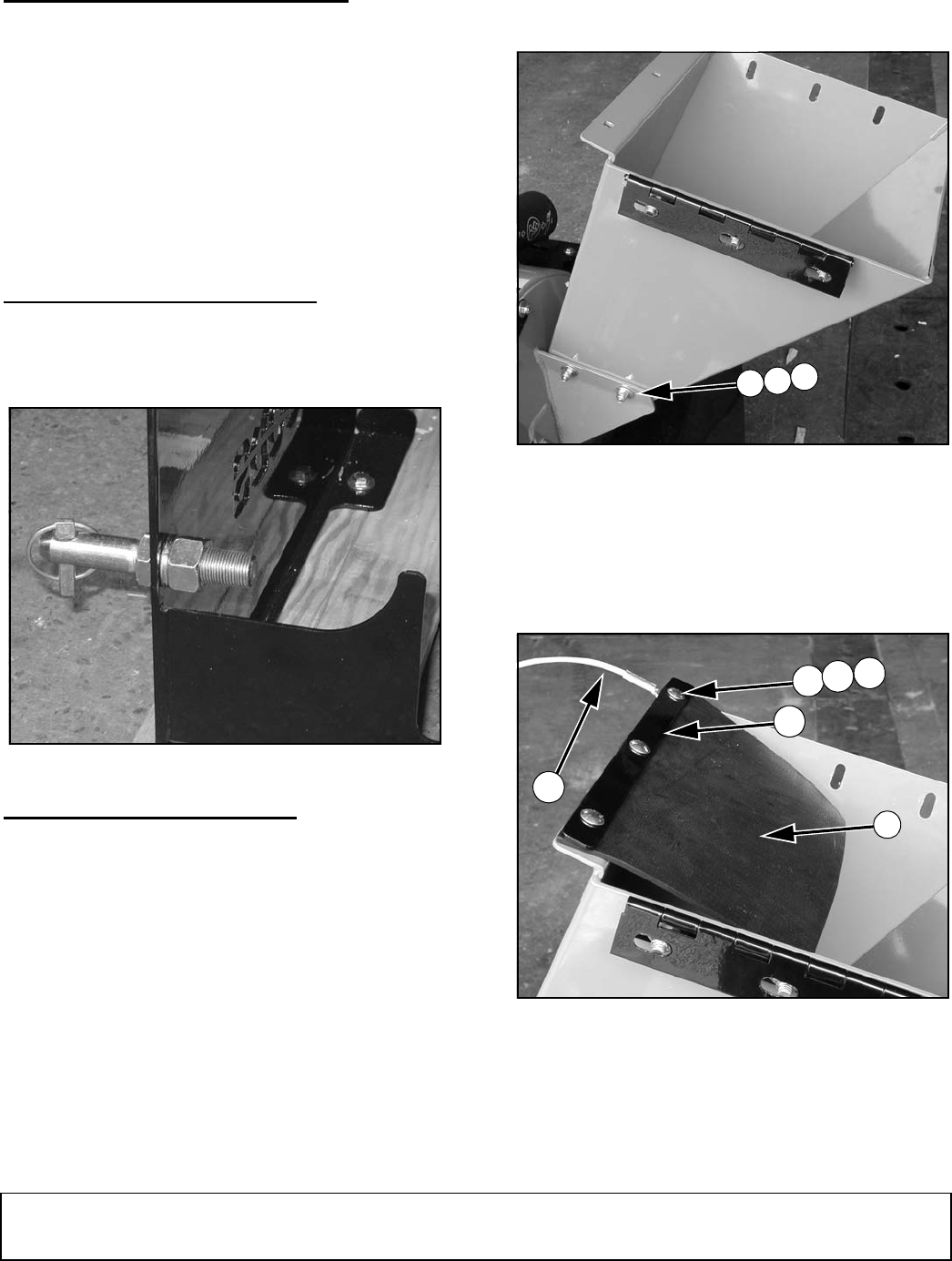

INSTALL 3-POINT HITCH PINS

1. Attach 3-point hitch pins to the chipper frame using

nuts and washers supplied with each pin.

2. Torque pins to 474 lbs-ft.

Figure 11. 3-Point Hitch Pin Installed, Left Pin Shown

INSTALL CHIPPER HOPPER

NOTE: Once all parts are installed and aligned torque

hardware to specifications listed below.

3/8 NC x 1 . . . . . . . . . . . . . . . 35 lbs-ft (47 N-m)

5/16 NC x 1 . . . . . . . . . . . . . . . 19 lbs-ft (26 N-m)

5/16 NC x 3/4. . . . . . . . . . . . . . 19 lbs-ft (26 N-m)

1. Attach chipper hopper to the chipper housing using

four carriage bolts (2), flat washers (1), and lock

nuts (3). See Figure 12 and Figure 17.

NOTE: Make sure the heads of the carriage bolts

are on the inside of the chute.

Figure 12. Chute and Hinge Installed

2. Attach rubber flap (8) to the chute flange using flap

retainer strap (9), three carriage bolts (12), flat

washers (13), and lock nuts (14). Attach lanyard

(10) between the chute flange and washer (13)

farthest from the hinge.

Figure 13. Rubber Flap and Lanyard Installed

3

2

1

DP4

10

DP5

12

9

8

13

14