Operation 13

MAN0458 (9/23/2005)

TRACTOR STABILITY

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up result-

ing in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Figure 1. Tractor Stability

STARTING THE CHIPPER

Do not put chipper into service unless all

shields and guards are in place and in good condi-

tion. Replace if damaged.

Make sure the cutting chamber is empty before

starting the machine.

Shift tractor transmission into park or neutral

and set brakes before engaging PTO and chipper.

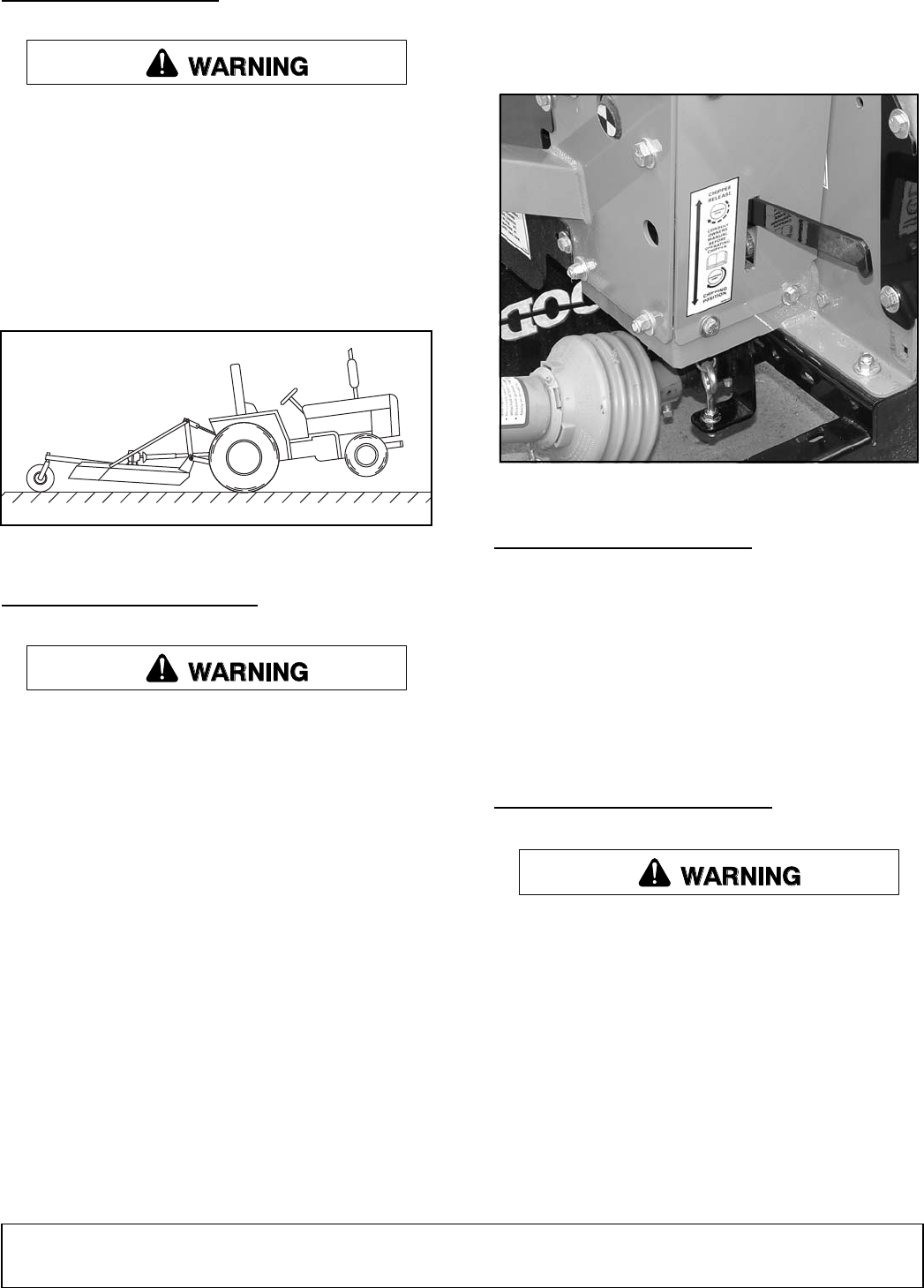

1. Make sure the cutting chamber is empty before

starting and the chipper engagement handle is in

the RELEASE (up) position.

2. Set parking brake, start the tractor, and engage the

tractor PTO.

3. Move the chipper engagemement handle to the

CHIPPING (down) position and increase the

engine speed to the rated PTO rpm position.

NOTE: Carefully engage the rotor by slowly moving the

engagement handle to the CHIPPING position, allow-

ing the rotor to speed up gradually, increase the throttle

to full throttle position. Engaging the clutch too quickly

with the engine at full or half throttle will bog down the

engine and will shorten the life of the belt.

Figure 2. Chipper Engagement Handle

STOPPING THE CHIPPER

1. Lower the tractor rpm’s.

2. Move the chipper engagement handle to the

RELEASE (up) position.

3. Disengage the tractor PTO handle and shut off the

engine.

4. Allow chipper to come to a complete stop.

CLEARING PLUGGED DISK

Keep hands and feet out of feed and discharge

openings while machine is operating to avoid seri-

ous personal injury. Turn off power and allow

machine to come to a complete stop before clear-

ing obstructions.

1. Remove the discharge cap.

2. Remove debris, taking care to avoid the chipper

blades which can be extremely sharp.

3. Replace discharge cap once debris is removed.

CD1564-2