Service 19

MAN0458 (9/23/2005)

Blade Clearance

IMPORTANT

■ Make sure that the clearance between the chip-

ping anvil and ALL chipper blades is set to 1/16".

All chipper blades should be rotated until even with

the chipping anvil and measured.

Figure 7. Anvil Clearance

The chipper blades should clear the chipping anvil by

1/16 inch. Anvil is located directly under the chipper

discharge opening. Follow steps to adjust the blade

clearance:

1. Remove the discharge cap or optional discharge

tube for easier access to the anvil.

2. Rotate the disk assembly until a chipper blade is

even with the chipping anvil.

3. Measure the amount of clearance between the

chipper blade and the chipping anvil from inside

the chipper housing. The minimum distance

between the blade and the anvil should be 1/16

inch.

4. Adjust the chipping anvil by loosening the 5/16

bolts holding the anvil to the disk cover and sliding

the anvil inward or outward until the 1/16 inch

clearance is achieved.

NOTE: If the chipping anvil is damaged or worn

unevenly, remove hardware holding anvil to the

disk cover. Rotate anvil to use one of the other

three edges.

5. Tighten hardware to 19 lbs-ft.

6. Install discharge cap or optional discharge tube.

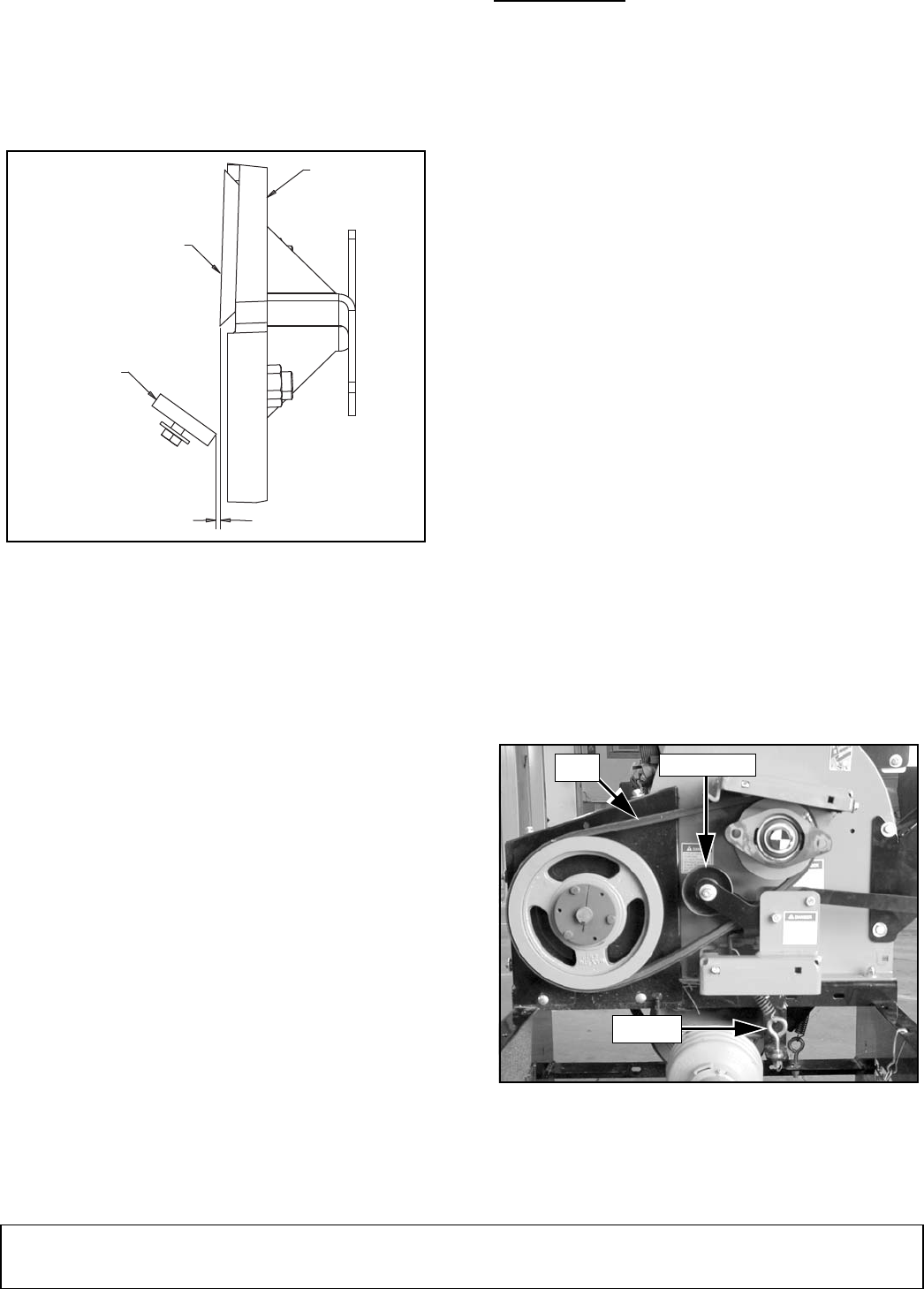

DRIVE BELT

Drive Belt Adjustment

Check the condition of the drive belt(s) annually or after

every 25 hours of operation. Replace cracked, frayed.

worn or stretched belt. Only replace drive belt with orig-

inal banded type belt. Do not use single type belts.

To adjust belt: tighten eyebolt until belt deflection is

7/16" when a 20-lb load is placed against the belt. See

Figure 9.

Front Drive Belt

Front Belt Removal

1. On a hard level surface lower chipper with 3-point

lift arms to the ground.

2. Move engagement lever to the RELEASE (up)

position.

3. Disconnect drive shaft, 3-point lift arms, and top

link from tractor.

4. Place drive shaft in storage position up off the

ground.

5. Remove belt shield from the chipper housing and

save hardware.

6. Remove bearing support weldment from the

chipper housing and save hardware.

7. Loosen the eyebolt to release tension on the belt.

8. Remove hardware and idler pulley from idler

bracket.

9. Remove old belt from around both sheaves.

Figure 8. Front Belt Drive Assembly

1/16"

Chipper Blade

Anvil

Disk

LA4

Idler Pulley

Belt

Eyebolt

DP2