CAUTION: Incorrect cable

adjustment couldcausethe

wheelsandtines to rotate

unexpectedly.Follow

adjustment procedures

carefully. Failureto do socould

result in personal injury or

property damage.

4. Checkfor correct spring/caNetension

as instructed in Section 5, Checkingand

Adjusting Forward Clutch Belt Tension.

5. Whentension iscorrect, tighten the two

jam nuts (B) securely.

STEP5: CHECKTRANSMISSIONGEAR

OILLEVEL

Thetransmission was filledwith gearoil at

the factory. However,besure to check the

oil level at this time to makecertain it is

correct.

IMPORTANT: Donot operatethe tiller if

the gearoil levelis low. Doingso will result

in severedamageto the transmission

components.

1. With the tiller on level ground, pull the

Depth Regulator Lever (R, Figure2-13)

backand then slide it to the second notch

from the top. NOTE:Ifthe lever does not

move, lift the tine hood flap and lookfor a

plastic tie securing the lever in place. Cut

and removethe tie.

2. Removethe oil levelcheck plug (M, Fig-

ure 2-10) on the left-side of the transmis-

sion. (Due to dried paint on the plug

threads, it may require some force to re-

move the plug the first time.) Thegear oil

level iscorrect if oilstarts to flow out ofthe

holeas the plug is removed. If so, securely

reinstall the plug.

Figure 2-10: Gear oil level checkplug.

3. If oil does not flow from the checkhole,

add oil as follows:

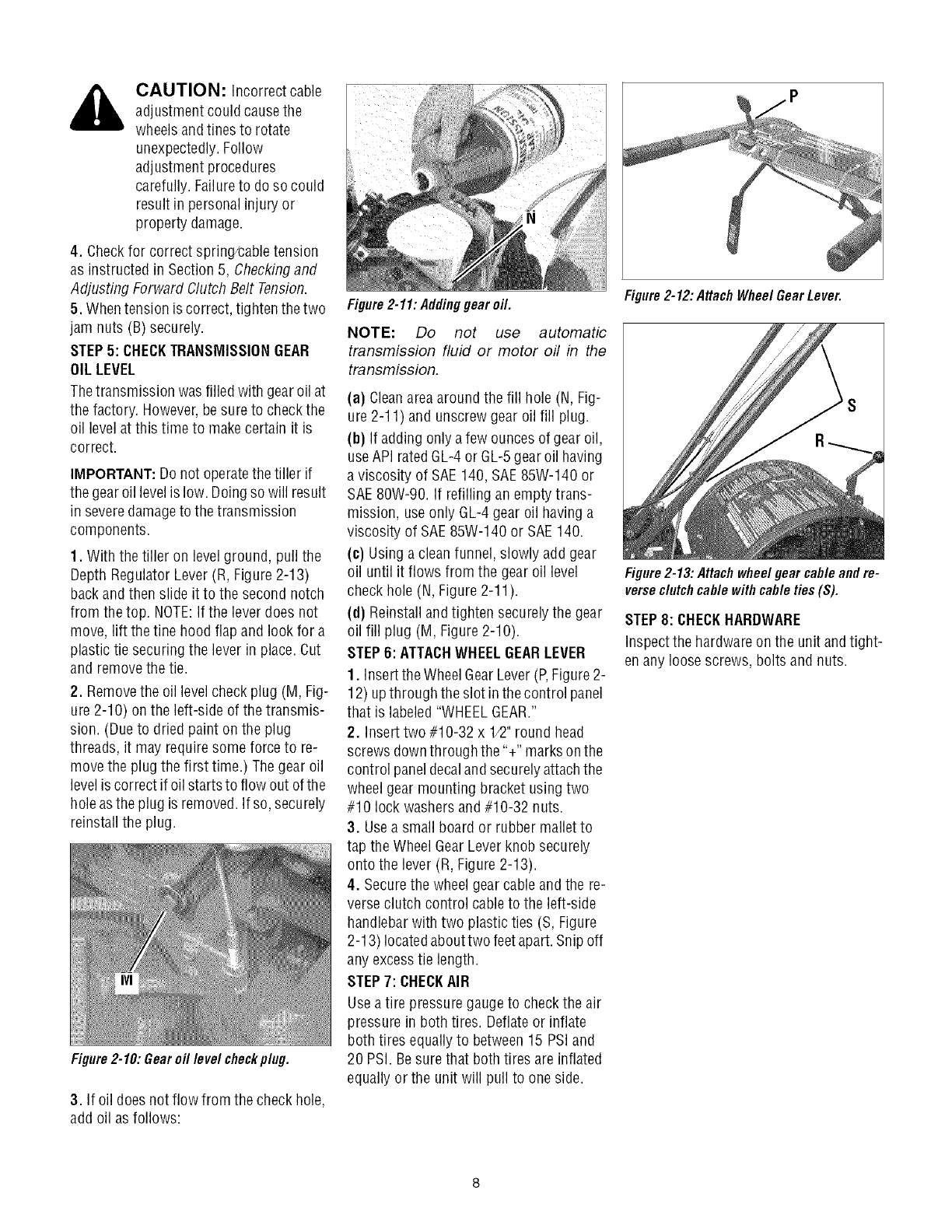

Figure2-11:Addinggearoil.

NOTE: Do not use automatic

transmission fluid or motor oil in the

transmission.

(a) Cleanareaaround the fill hole (N, Fig-

ure 2-11) and unscrewgear oil fill plug.

(b) If adding onlya few ounces of gear oil,

use APIrated GL-4or GL-5gearoil having

a viscosity of SAE140, SAE85W-140 or

SAE80W-90. If refilling an emptytrans-

mission, useonly GL-4gear oil having a

viscosity of SAE85W-140 or SAE140.

(c) Using aclean funnel, slowly add gear

oil until it flows from the gear oil level

check hole (N, Figure2-11).

(d) Reinstall and tighten securelythe gear

oil fill plug (M, Figure2-10).

STEP6: ATTACHWHEELGEARLEVER

1. Insert the WheelGearLever (P,Figure 2-

12) upthrough theslot in thecontrol panel

that is labeled"WHEELGEAR."

2. Insert two #10-32 x 1/2"round head

screws downthrough the'%" marks onthe

control paneldecalandsecurelyattachthe

wheel gear mounting bracket using two

#10 lock washersand #10-32 nuts.

3. Usea small board or rubber malletto

tap the Wheel GearLever knob securely

onto the lever (R, Figure2-13).

4. Securethe wheelgear cable and the re-

verseclutch control cableto the left-side

handlebarwith two plastic ties (S, Figure

2-13) locatedabout two feetapart.Snip off

any excesstie length.

STEP7: CHECKAIR

Usea tire pressuregauge to checkthe air

pressure in both tires. Deflateor inflate

both tires equally to between15 PSiand

20 PSI. Besure that both tires are inflated

equally or the unit will pull to one side.

Figure2-12: AttachWheel Gear Lever.

Figure2-13:Attachwheelgearcableandre-

verseclutchcablewithcableties(S).

STEP8: CHECKHARDWARE

Inspectthe hardware on the unit andtight-

en anyloose screws, bolts and nuts.